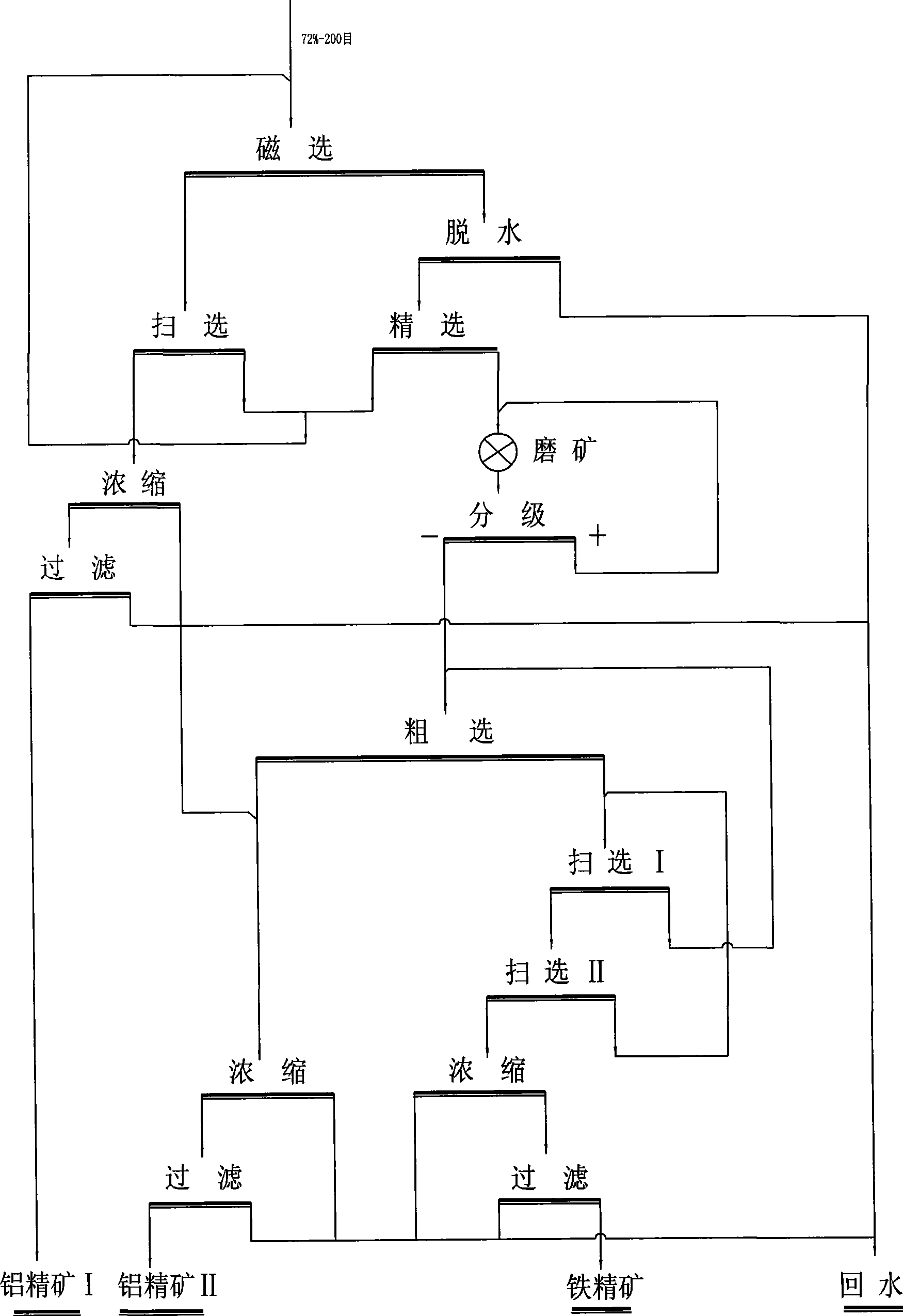

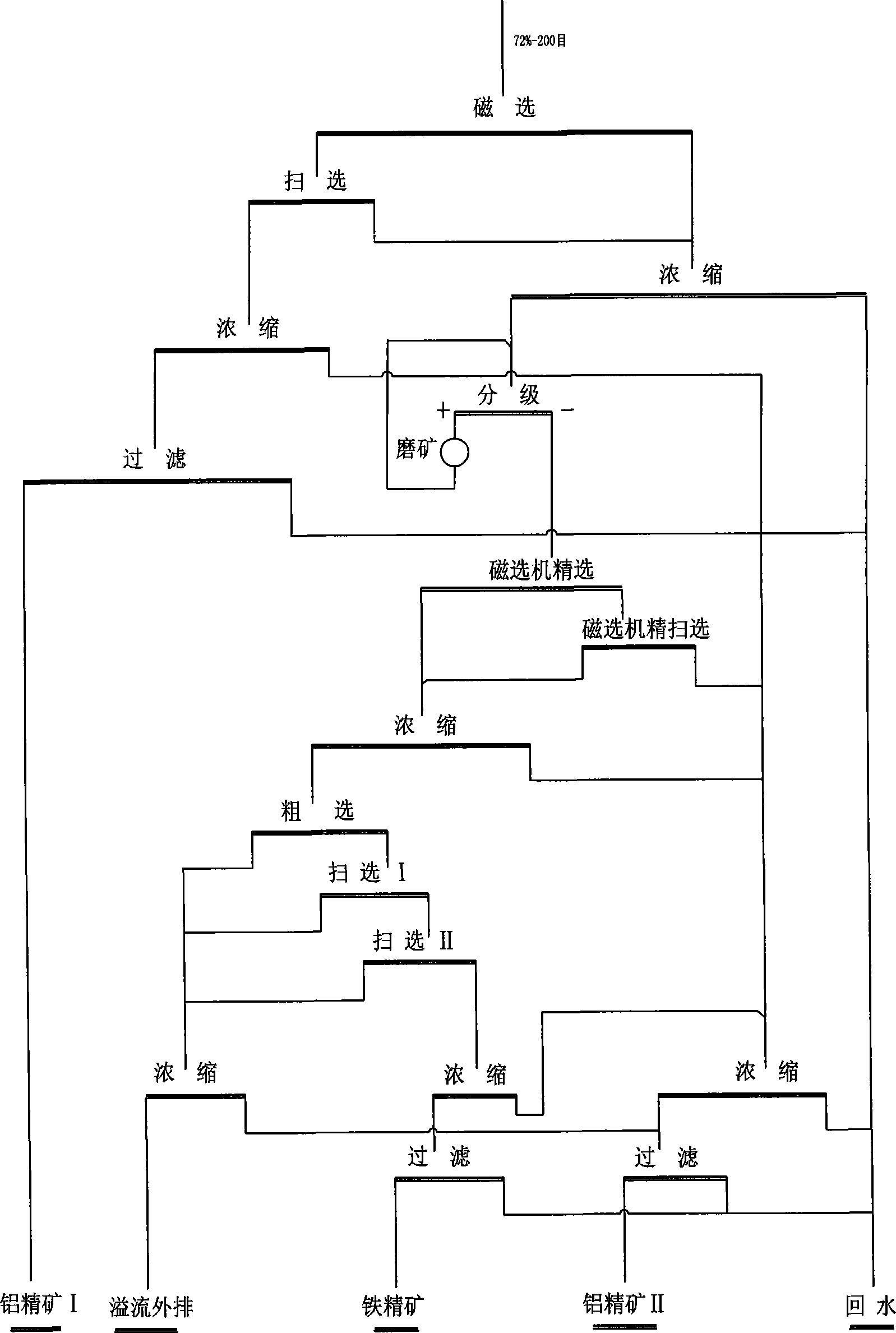

High iron bauxite dressing method

A technology for high-speed iron bauxite and beneficiation methods, applied in chemical instruments and methods, flotation, wet separation and other directions, can solve problems such as adverse effects and adverse effects on the grade of iron concentrates, and achieve continuous and stable production and improve quality. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

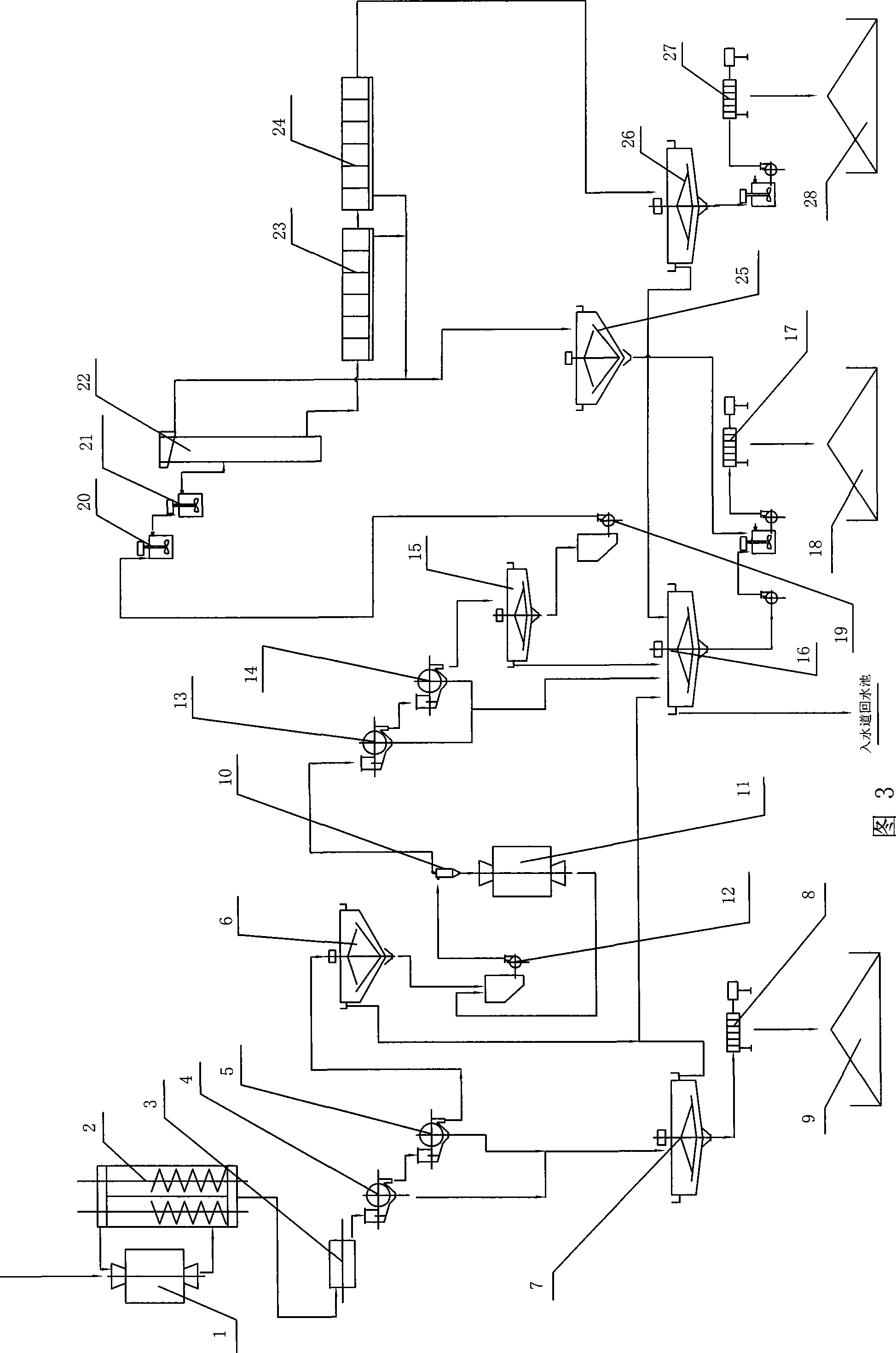

[0022] The raw ore goes through crushing and grinding 1 and 2, and the particle size of the product reaches 72%-200 mesh. It enters the first coarse and first sweep magnetic separation operation drum sieve 3 to separate the slag, and the pulp of the drum sieve 3 enters the vertical ring pulsating high gradient magnetic separator 4, the vertical ring The concentrate from the pulsating high-gradient magnetic separator 4 enters the vertical ring pulsating high-gradient magnetic separator 5, and the magnetically separated concentrates from the magnetic separation operations 4 and 5 pass through concentration 6 and the bottom flow is pumped into the cyclone 11 by the sand pump 12; the vertical ring pulsating The tailings of high-gradient magnetic separator 4 and 5 go into the thickener 7 filter 8 and the filtered product is high-grade aluminum concentrate I9, Al 2 o 3 The grade is 65-70%, and the recovery rate is 55%. The underflow of the cyclone 11, the underflow concentration is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com