Foundation treatment water drain structure of geotextile filter tube vacuum preloading method

A vacuum preloading method and foundation treatment technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as large impact and loss, high price, and shortage of medium and coarse sand resources, and achieve short construction period and low cost. Low, reduce the effect of loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

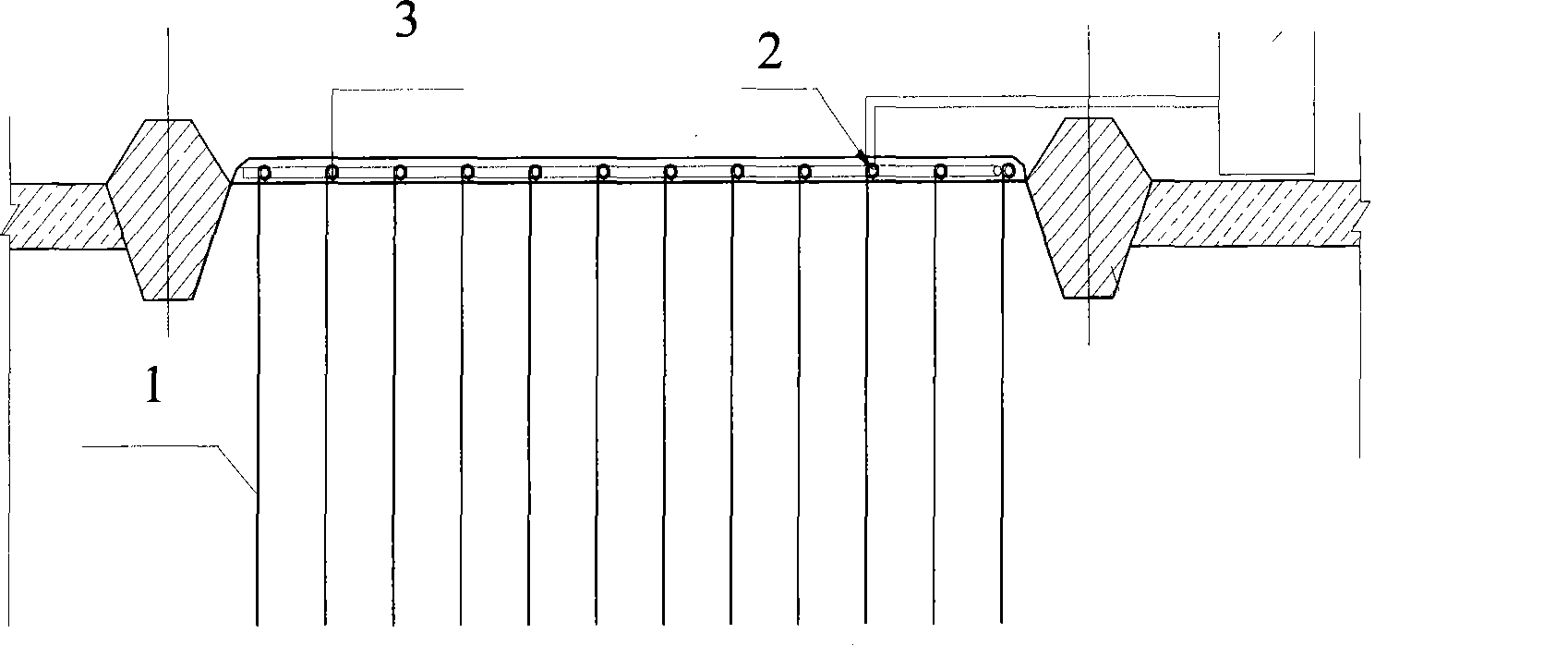

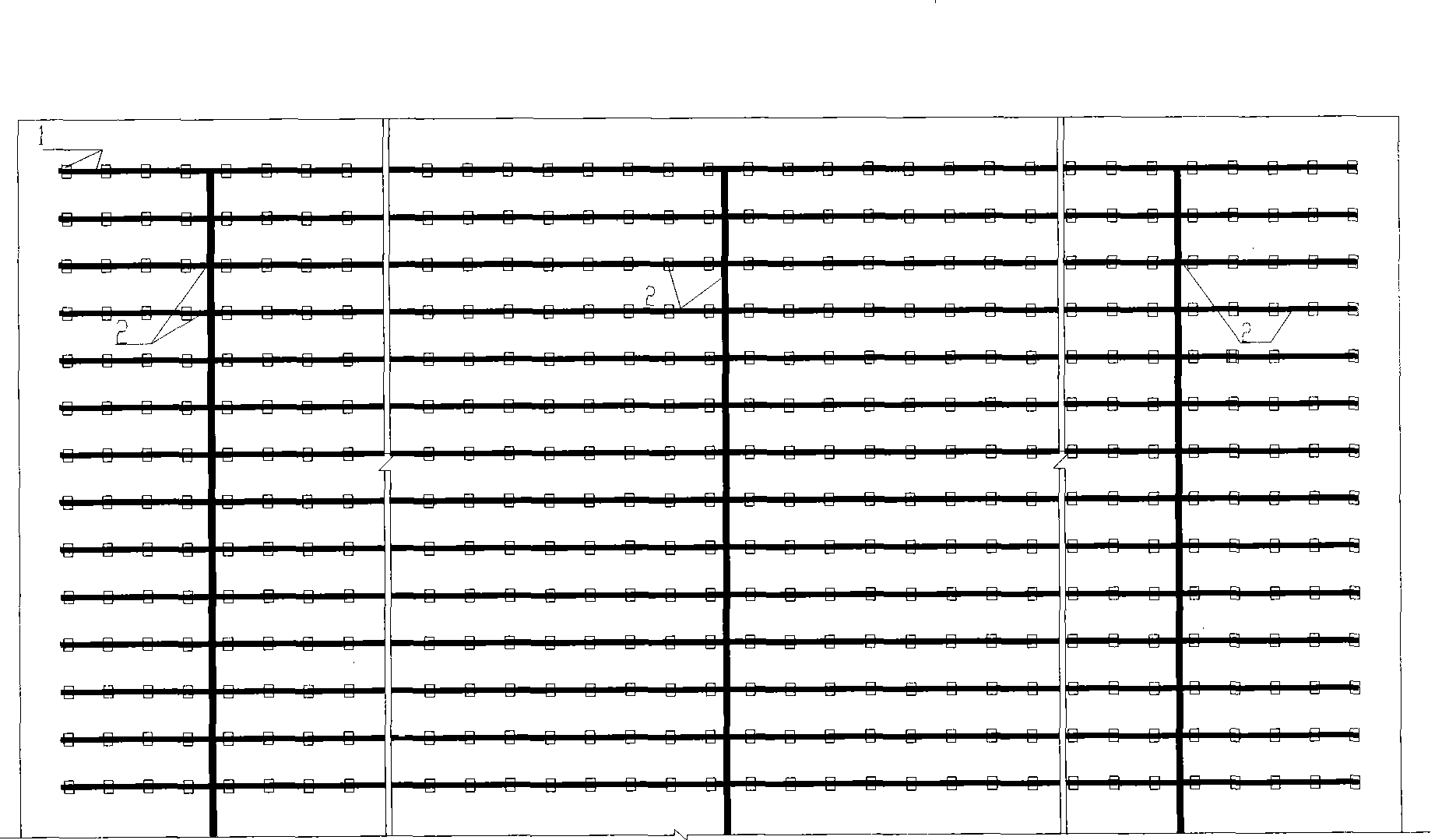

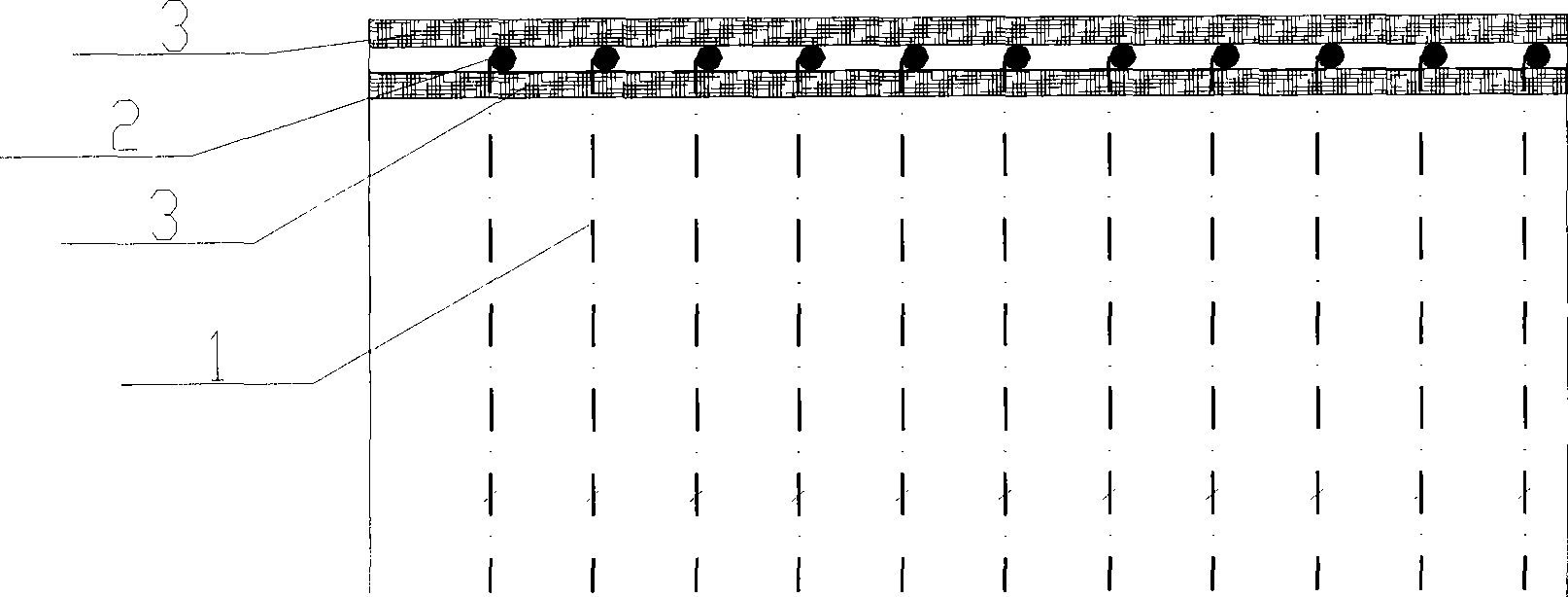

[0014] The application of the drainage structure of the geotextile filter tube vacuum preloading method foundation treatment of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The drainage structure of the geotextile filter tube vacuum preloading method ground treatment of the present invention follows the reinforcement mechanism of the traditional vacuum pressure method ground treatment, and the structure is based on the traditional vacuum preloading method ground treatment. Optimized processing.

[0016] The geotextile filter tube vacuum preloading drainage structure of the present invention includes a drainage system and a sealed vacuum system. The drainage system includes a plastic drainage board 1 embedded in the soil, a filter pipe 2 and a plastic drainage system. The plate joints are directly connected, and a layer of geotextile 3 for protecting the filter tube is respectively arranged on the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com