Support plate for elements of flat membrane bioreactor

A bioreactor and support plate technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems affecting membrane separation efficiency and selectivity, large pressure loss, etc. , to avoid local pressure loss, improve balance, and reduce suction loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

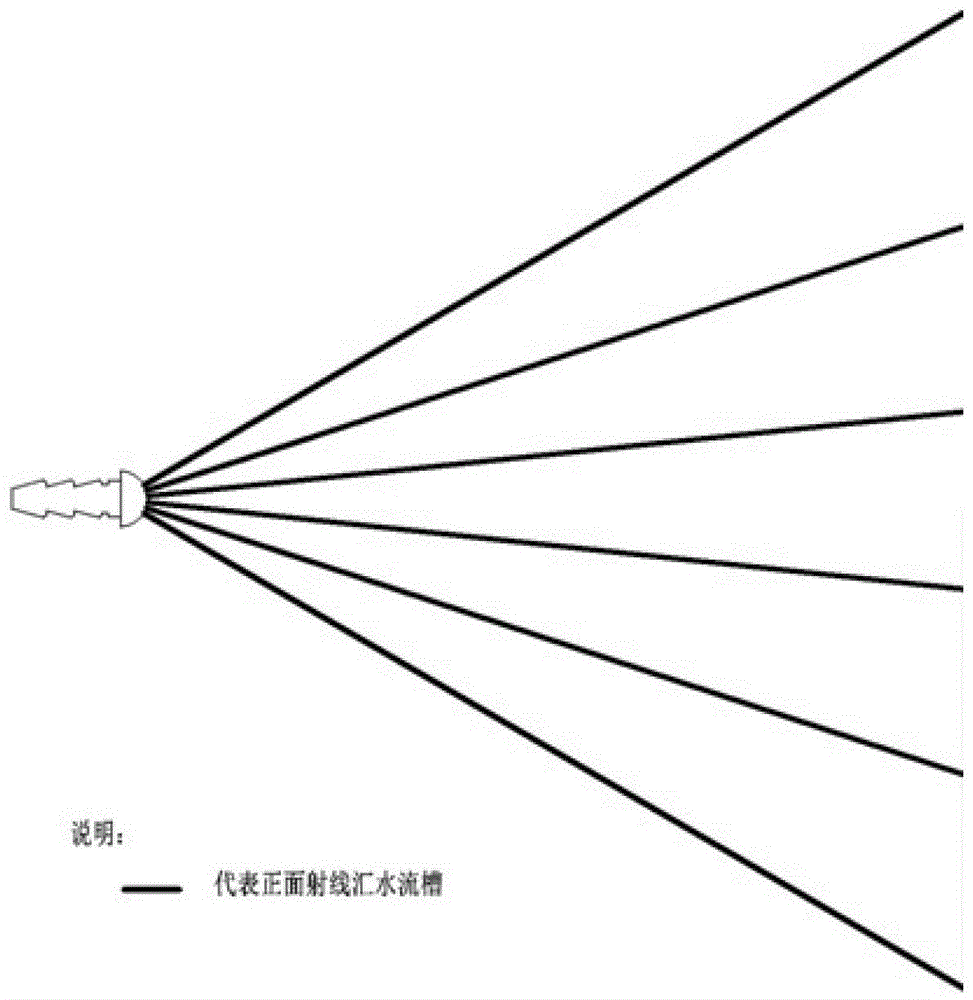

[0036] Such as figure 1 Shown: a support plate for a flat membrane bioreactor element, the surface of the support plate is arranged with a water flow groove, the water flow groove is connected to the water outlet, the water flow groove is arranged on one side of the support plate, and the water flow groove is connected to the water outlet The ray catchment trough for the emission point is arranged in a fan shape.

Embodiment 2

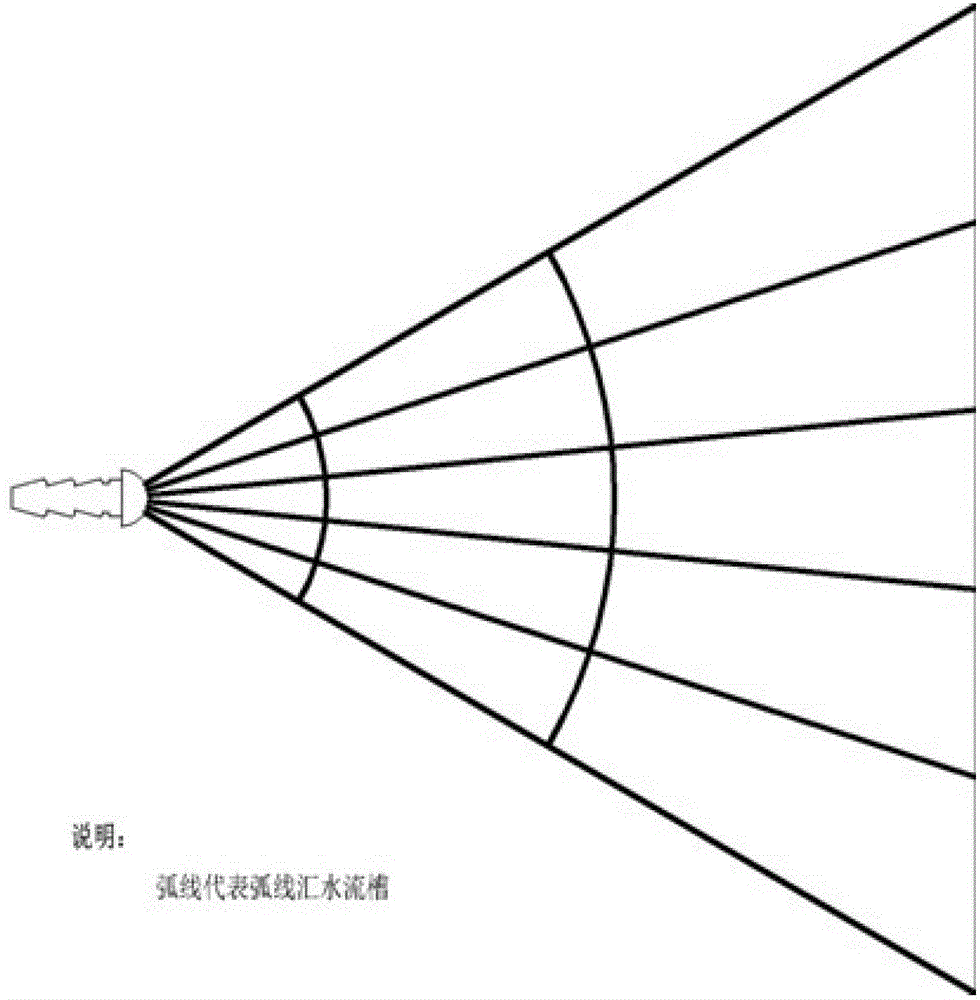

[0038] A support plate for a flat membrane bioreactor element, the surface of the support plate is arranged with a water collection flow channel, the water collection flow channel is connected to the water outlet, the water collection flow channel is symmetrically arranged on both sides of the support plate, and the water collection flow channel is launched from the water outlet Point ray catchment troughs are arranged in a fan shape.

Embodiment 3

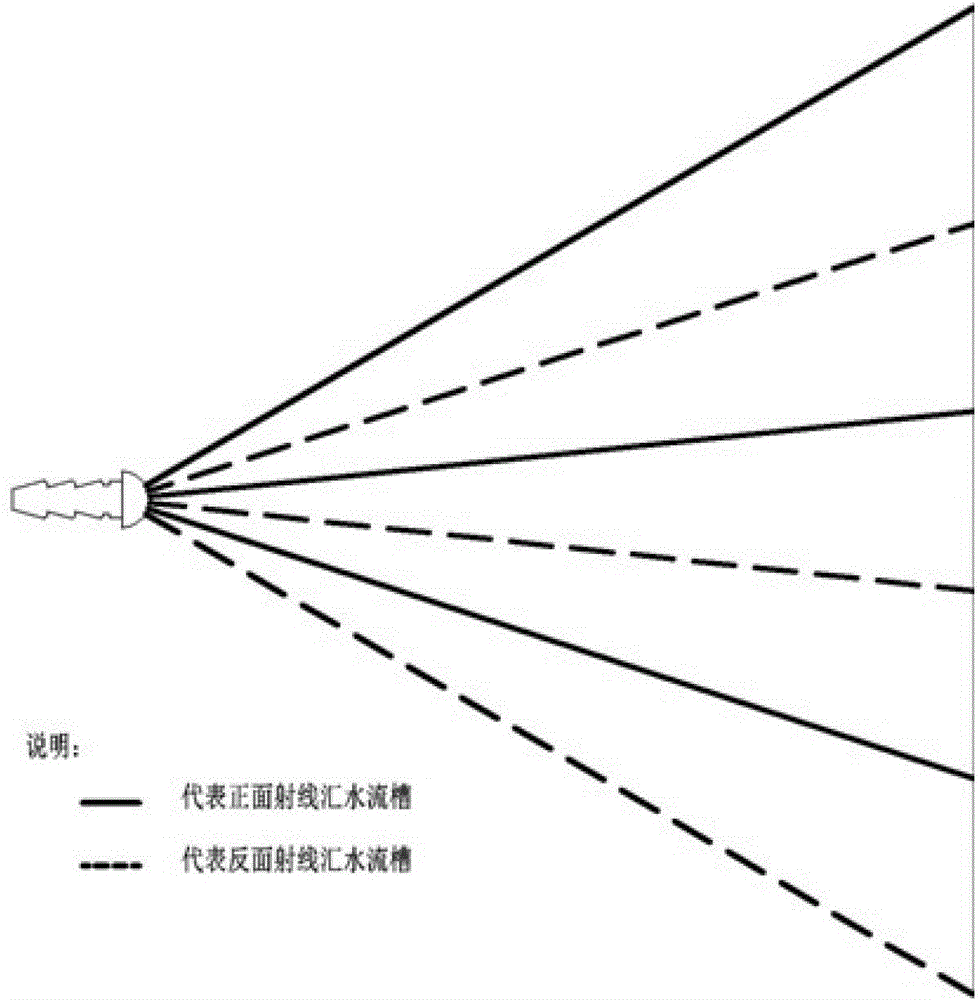

[0040] Such as figure 2 Shown: a support plate for a flat membrane bioreactor element, the surface of the support plate is arranged with a water flow groove, the water flow groove is connected to the water outlet, the water flow groove is staggered on both sides of the support plate, and the water flow groove is based on the water outlet The ray catchment trough for the emission point is arranged in a fan shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com