Method for implementing thick copper wire down-lead bonding

A technology of wire bonding and implementation method, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve unapplied problems, and achieve the effects of saving gold, strong welding wire and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

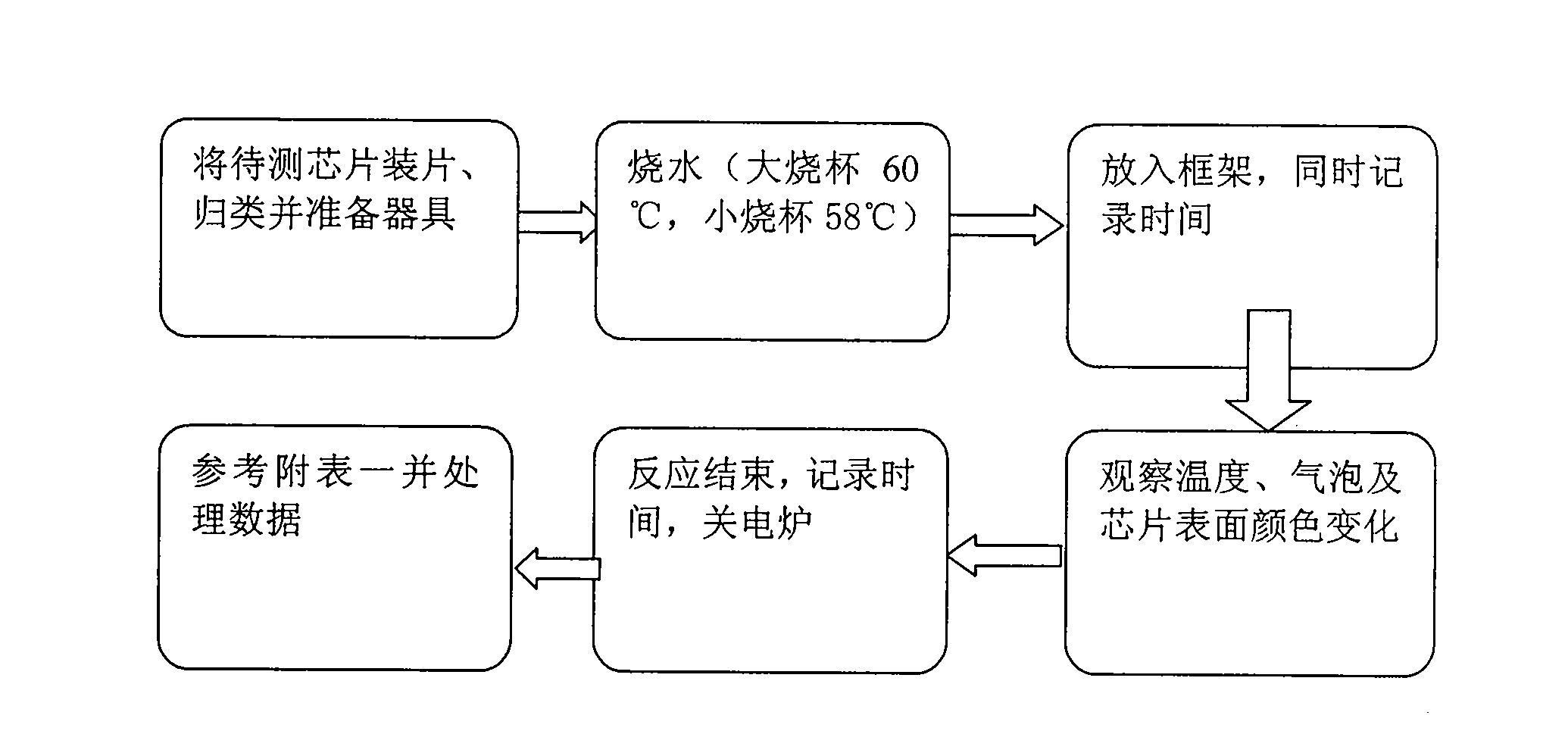

[0039] The main technical key points of the present invention are: protection of copper balls during crystallization, design optimization of a chopper, detection of chip aluminum layer thickness, and optimized matching of key process parameters.

[0040] Protection when the copper ball crystallizes

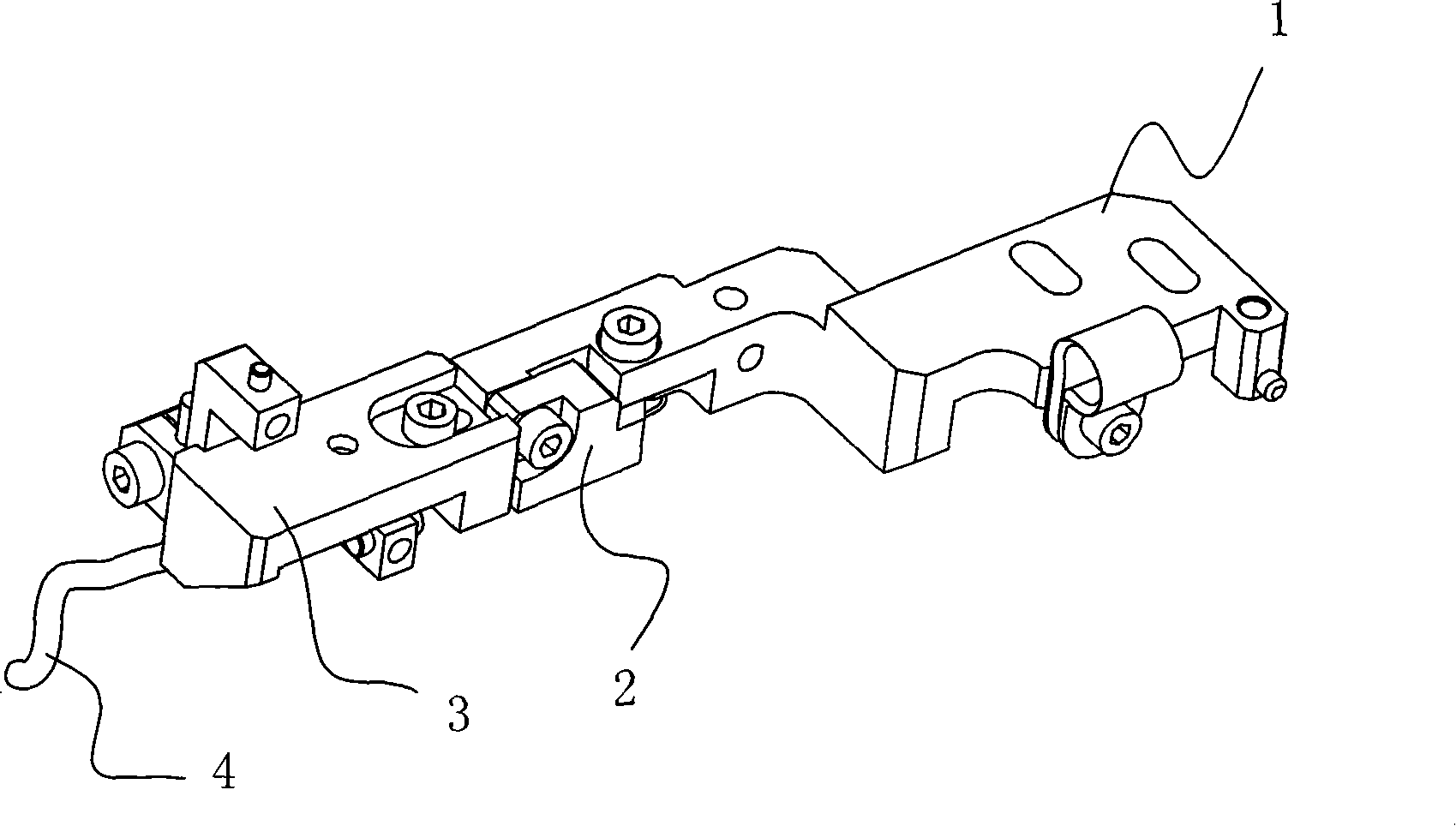

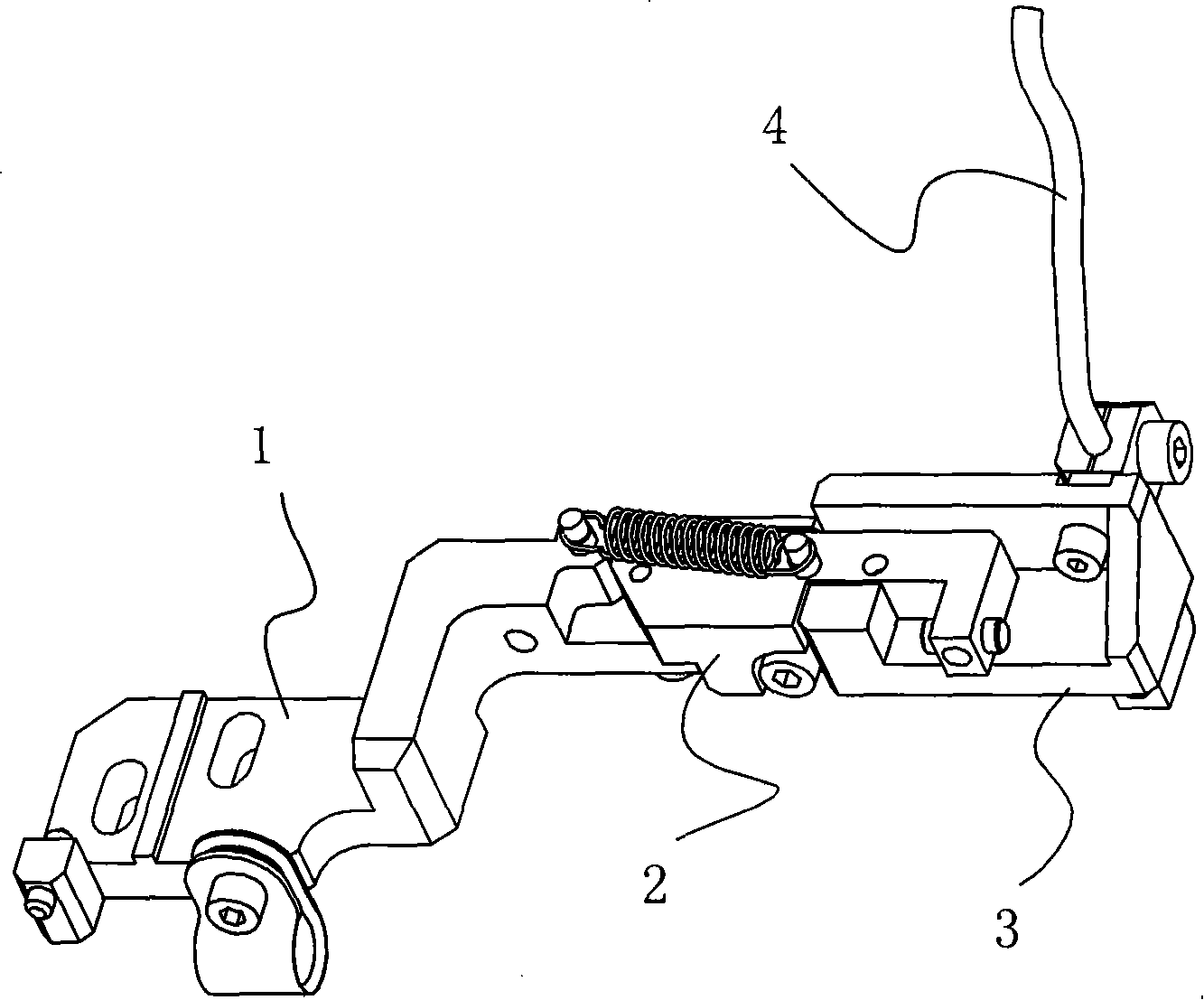

[0041] The protective gas device consists of four parts: the fixed foot 1 of the protective gas device fixed to the equipment, the first intermediate connection section 2, the second intermediate connection section 3, and the nozzle 4 of the protective gas device. The diameter of the nozzle requires φ2mm.

[0042] The fixed foot 1 of the shielding gas device is fixed on the welding head of the equipment, and the material of the fixed foot is aluminum alloy; the first intermediate connecting section 2 is connected with the fixed foot 1 of the shielding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com