Method and device for measuring ultrasonic wave coal wall temperature

A temperature measurement and ultrasonic technology, applied in the field of temperature measurement devices, can solve the problems of temperature sensing element structure, strict performance requirements, unfavorable for coal wall temperature measurement, inability to perform accurate measurement, etc. Low, low-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation

[0018] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

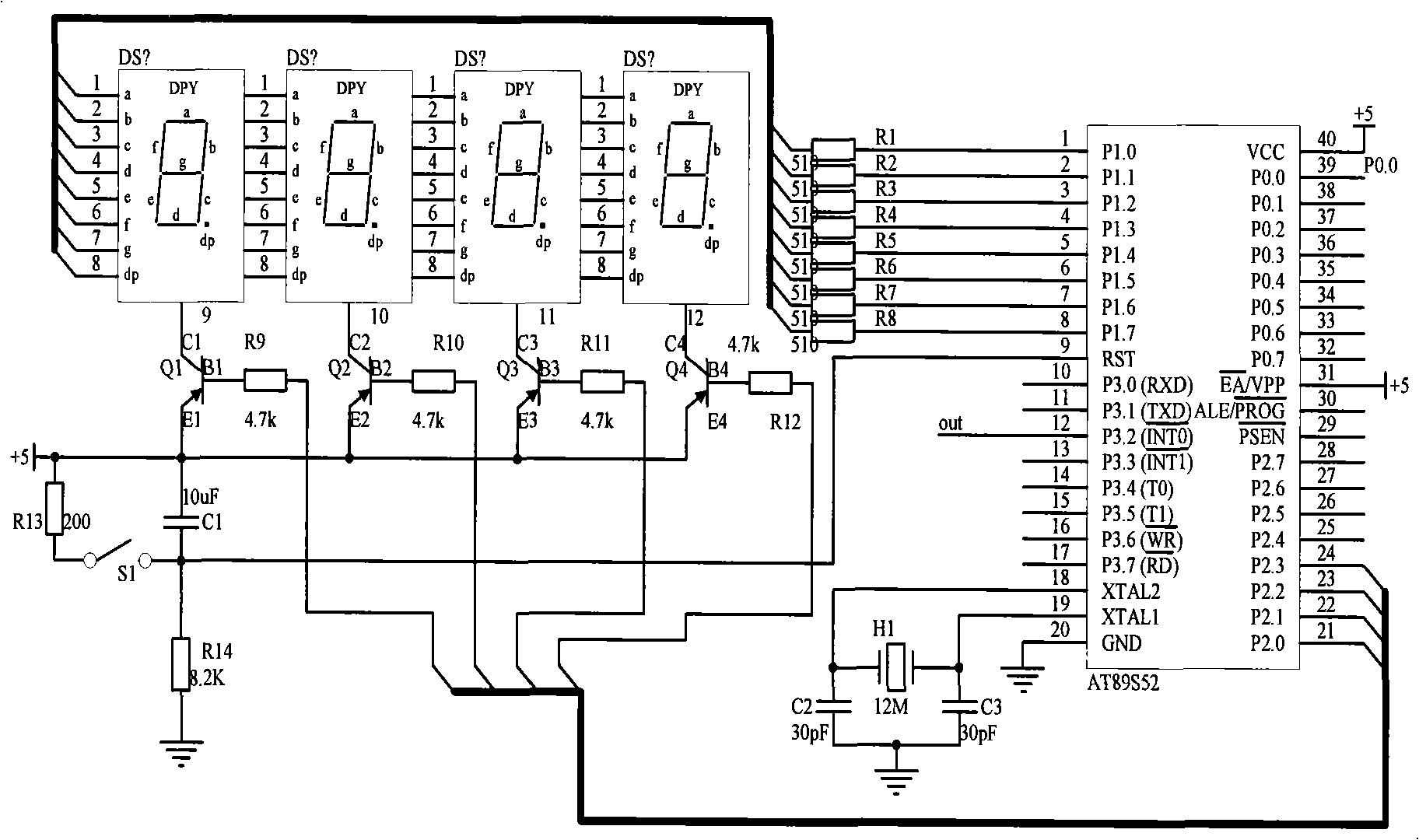

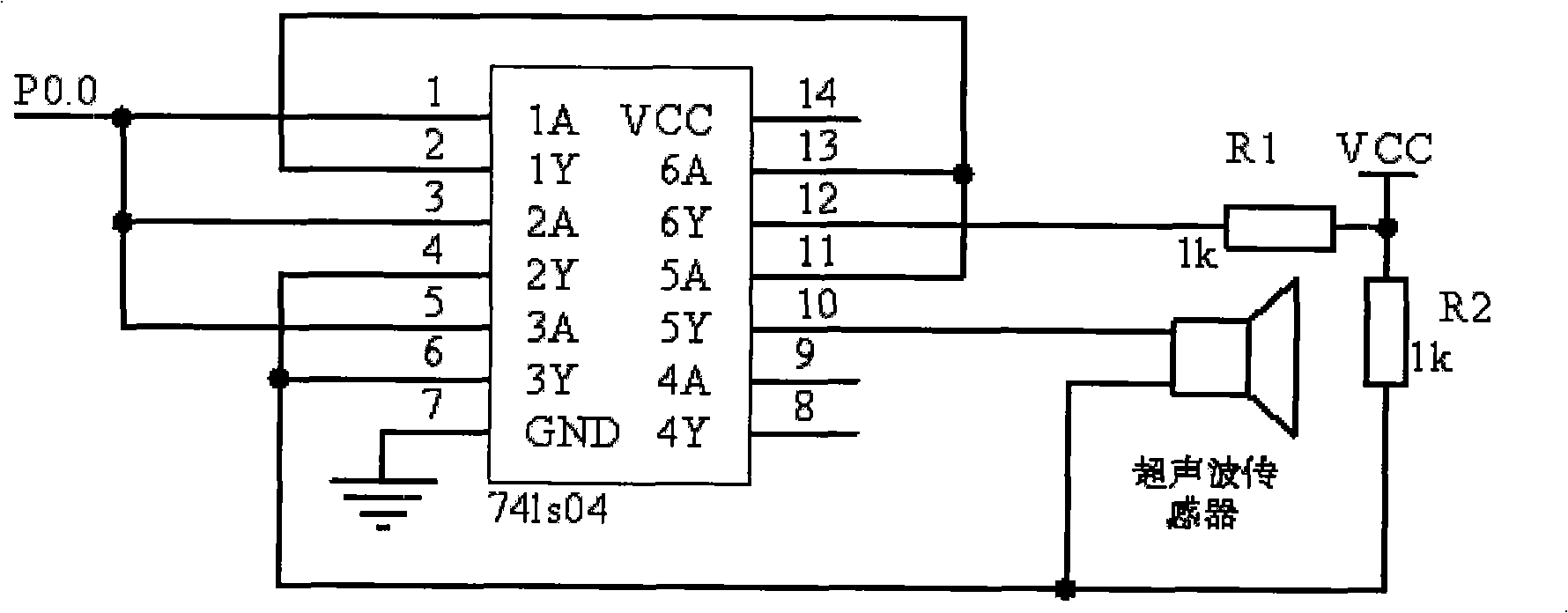

[0019] figure 1 As shown, the ultrasonic temperature measuring device mainly includes a single-chip microcomputer circuit, a digital display, an ultrasonic transmitting circuit, an ultrasonic receiving circuit and an ultrasonic sensor. The ultrasonic sensor is connected to the ultrasonic transmitting circuit and the ultrasonic receiving circuit at the same time. It is connected with the ultrasonic receiving circuit, and the single-chip microcomputer circuit is connected with the digital display. Among them, the model of the ultrasonic sensor is TCF40-25TR1, the microcontroller circuit adopts AT89S52, the model of the digital display is SM410561K, the driving chip of the ultrasonic transmitting circuit adopts the inverter 74ls04, and the receiving chip model of the ultrasonic receiving circuit is CX20106A. The single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com