Method for inhibiting carbon dioxide released by mineralizing organic material

A technology of organic materials and ferric hydroxide is applied in the field of inhibiting the release of carbon dioxide from the mineralization of organic materials, which can solve the problems of occupying large land resources and air pollution, and achieve the effects of inhibiting the release of mineralization, reducing the degradation rate, and inhibiting the degradation of mineralization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

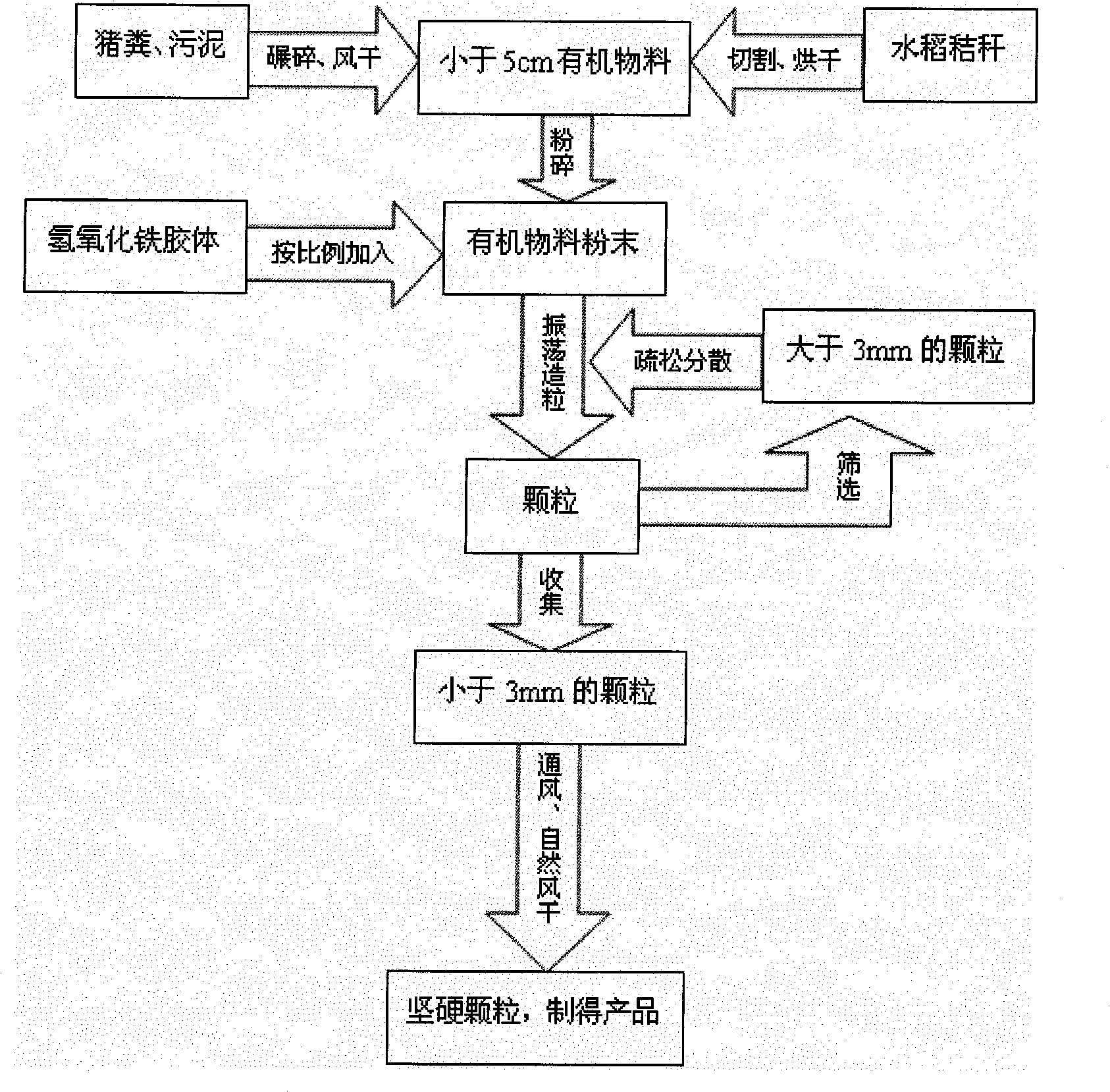

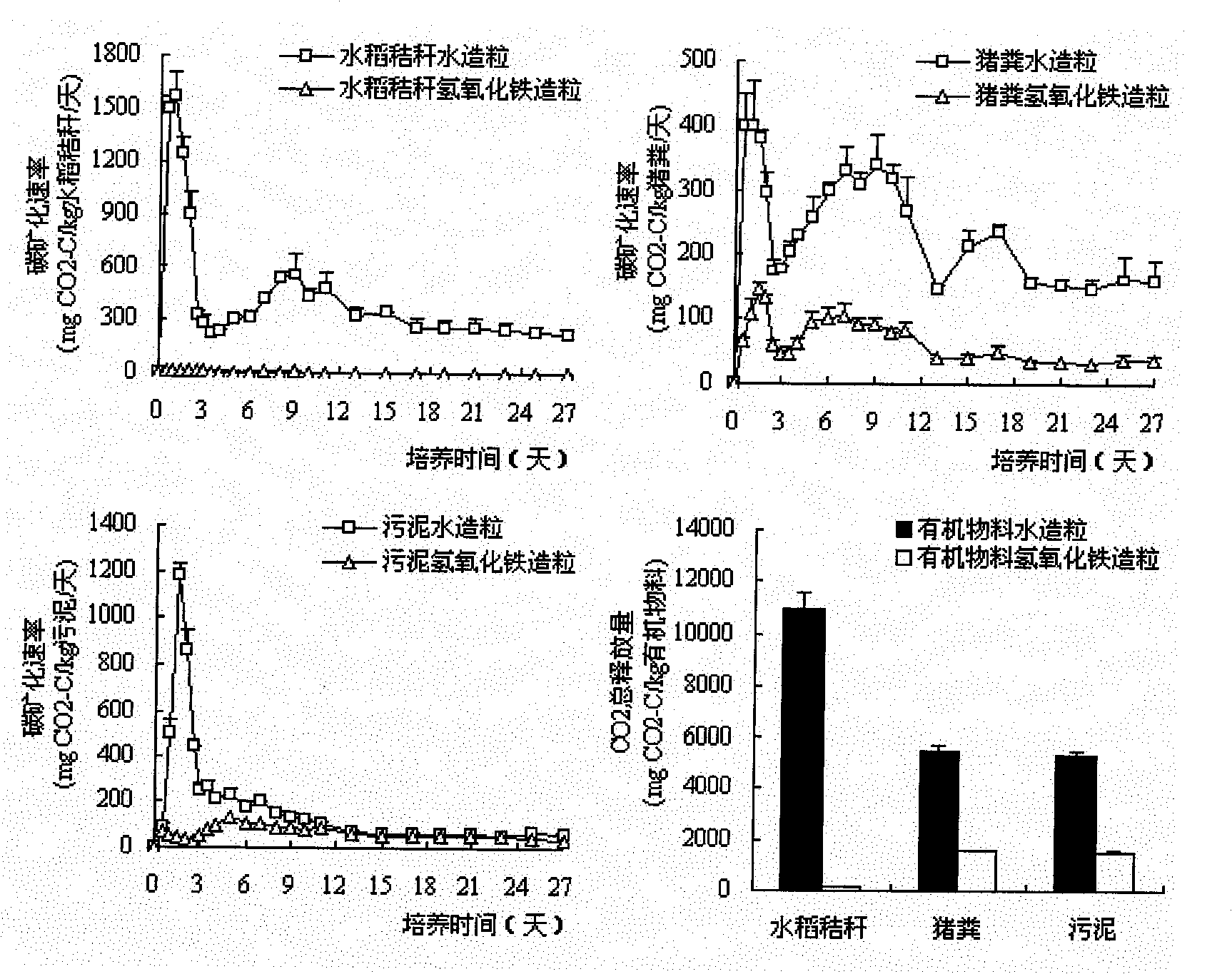

[0029] Refer to attached figure 1 , figure 2 and image 3 .

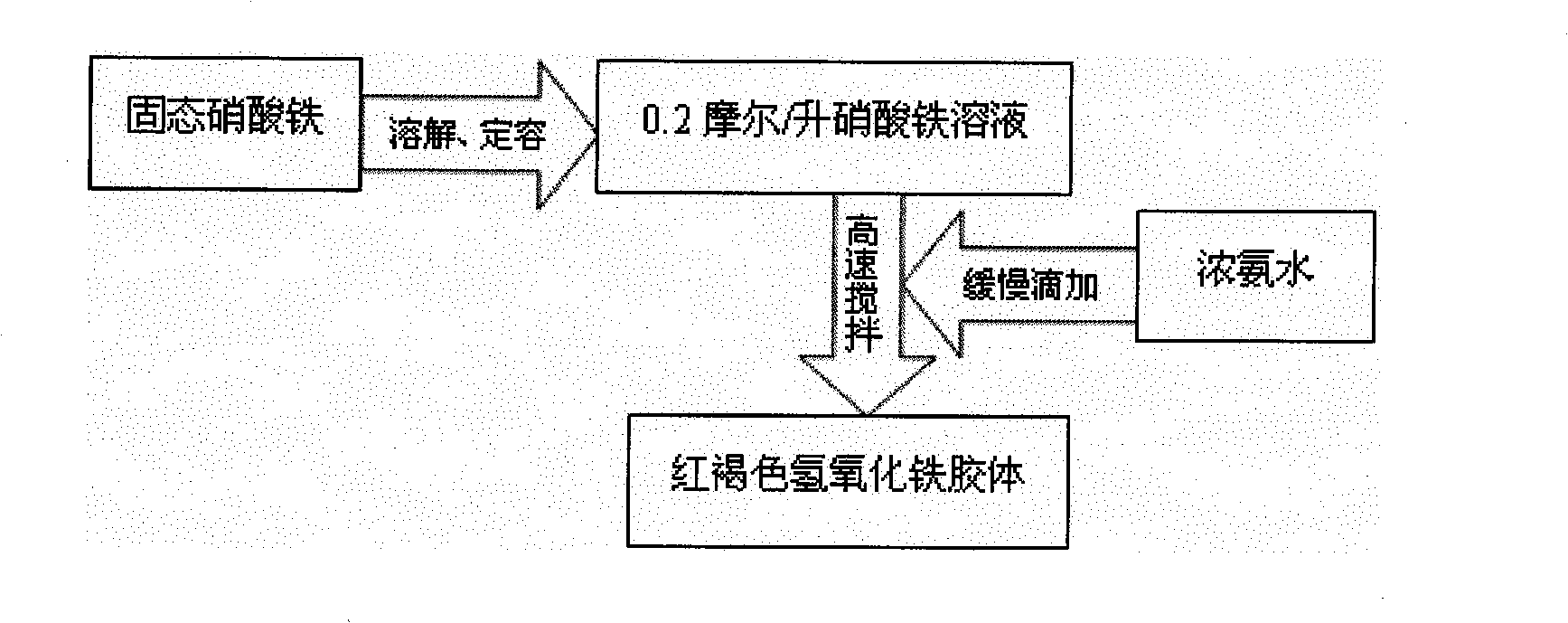

[0030] The organic material processing method of the present invention collects sludge, pig manure or rice straw respectively, pulverizes the bulk sludge and pig manure and air-dries them, cuts and dries the rice straw, and pulverizes them into 60-mesh powder. According to the formula ratio of 10 grams of organic material powder: 5 milliliters of ferric hydroxide colloid, granulate respectively, and in addition, granulate according to the formula ratio of 10 grams of powder: 5 milliliters of deionized water as a control, respectively make sludge, pig manure or rice straw Water-based granules and ferric hydroxide colloidal granules. Pellets with a particle size of less than 3mm were collected and air aged until hard and dry. Weigh a certain amount of granules and put them into a culture bottle, adjust the water to 60% of the maximum water holding capacity of each organic material, plug the bottle tightly, cultiv...

Embodiment 2

[0041] Refer to attached figure 1 , figure 2 and Figure 4 .

[0042] The organic material treatment method is to collect sludge, pig manure or rice straw separately, crush and air-dry the bulk sludge and pig manure, cut and dry the rice straw, and crush it into 60-mesh powder. According to the formula ratio of 10 grams of organic material powder: 5 milliliters of ferric hydroxide colloid, granulate respectively, and in addition, granulate according to the formula ratio of 10 grams of powder: 5 milliliters of deionized water as a control, respectively make sludge, pig manure or rice straw Water-based granules and ferric hydroxide colloidal granules. Pellets with a particle size of less than 3mm were collected and air aged until hard and dry. Weigh a certain amount of granules and put them into nylon mesh bags, and bury them in the farmland for natural mineralization. Samples were taken regularly from the date of embedding to measure the organic carbon content and calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com