Vertical reaction device for preparing nano carbon fibre in batch

A technology of carbon nanofibers and a reaction device, which is applied in the field of reaction devices for preparing carbon nanofibers, and devices for preparing tubular and solid carbon nanofibers in batches, can solve the problems of low temperature, inability to reach the graphitization temperature, and inability to master the process of solid carbon nanofibers, etc. Achieve the effect of increasing productivity and increasing the probability of contact

Inactive Publication Date: 2010-11-24

HUNAN UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The shape of tubular carbon nanofibers is similar to that of multi-walled carbon nanotubes, and the production process is easier to control; while the formation of solid nanocarbon fibers may be due to the low temperature in the local growth area, which cannot reach the graphitization temperature.

None of the existing equipment can solve the problem of the temperature gradient in the reaction chamber, so it is still impossible to master the process of preparing solid nano-carbon fibers, and there is no method for continuously preparing solid nano-carbon fibers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

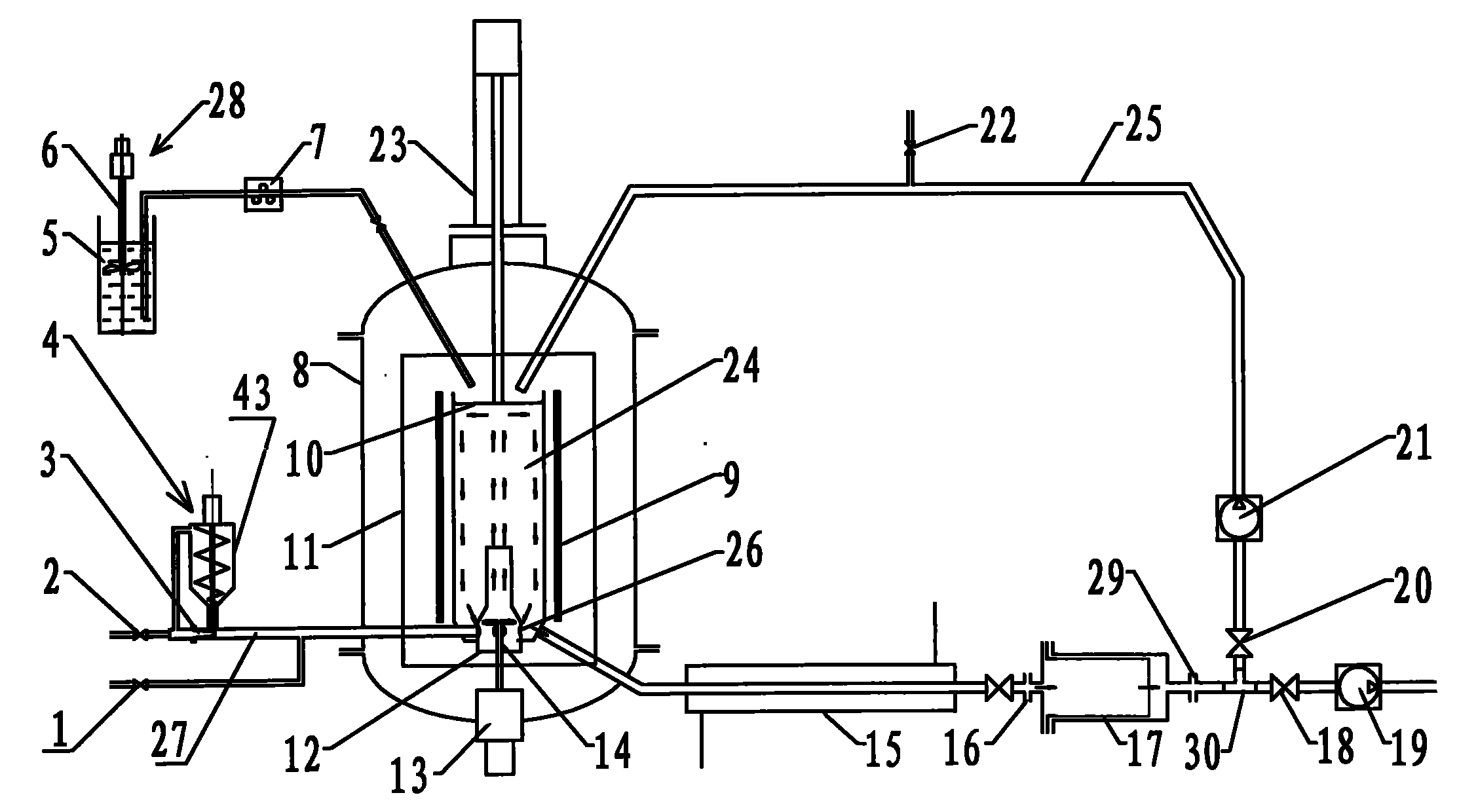

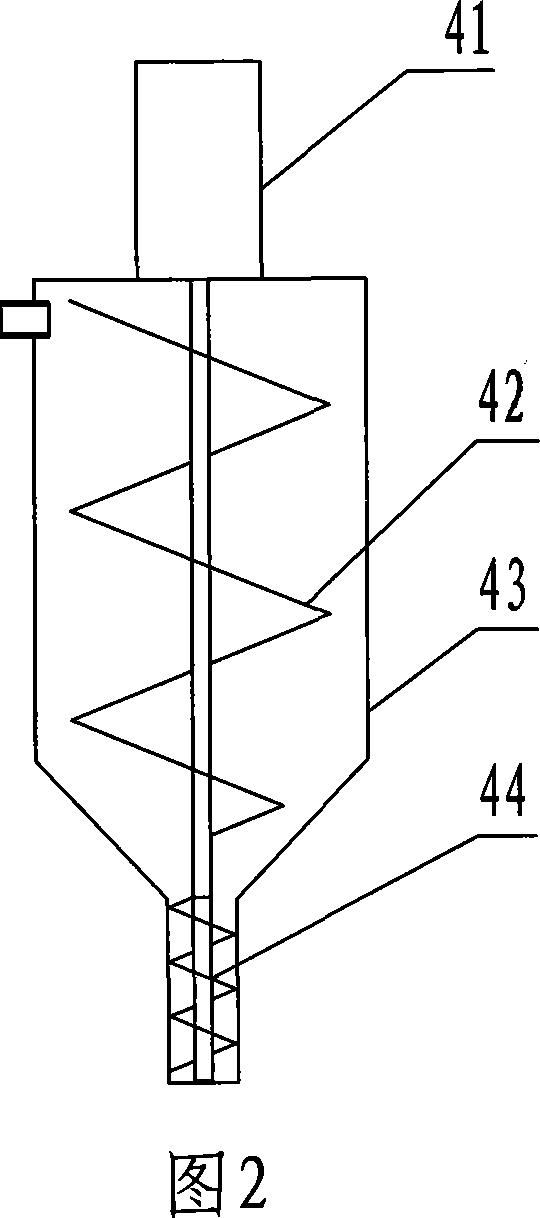

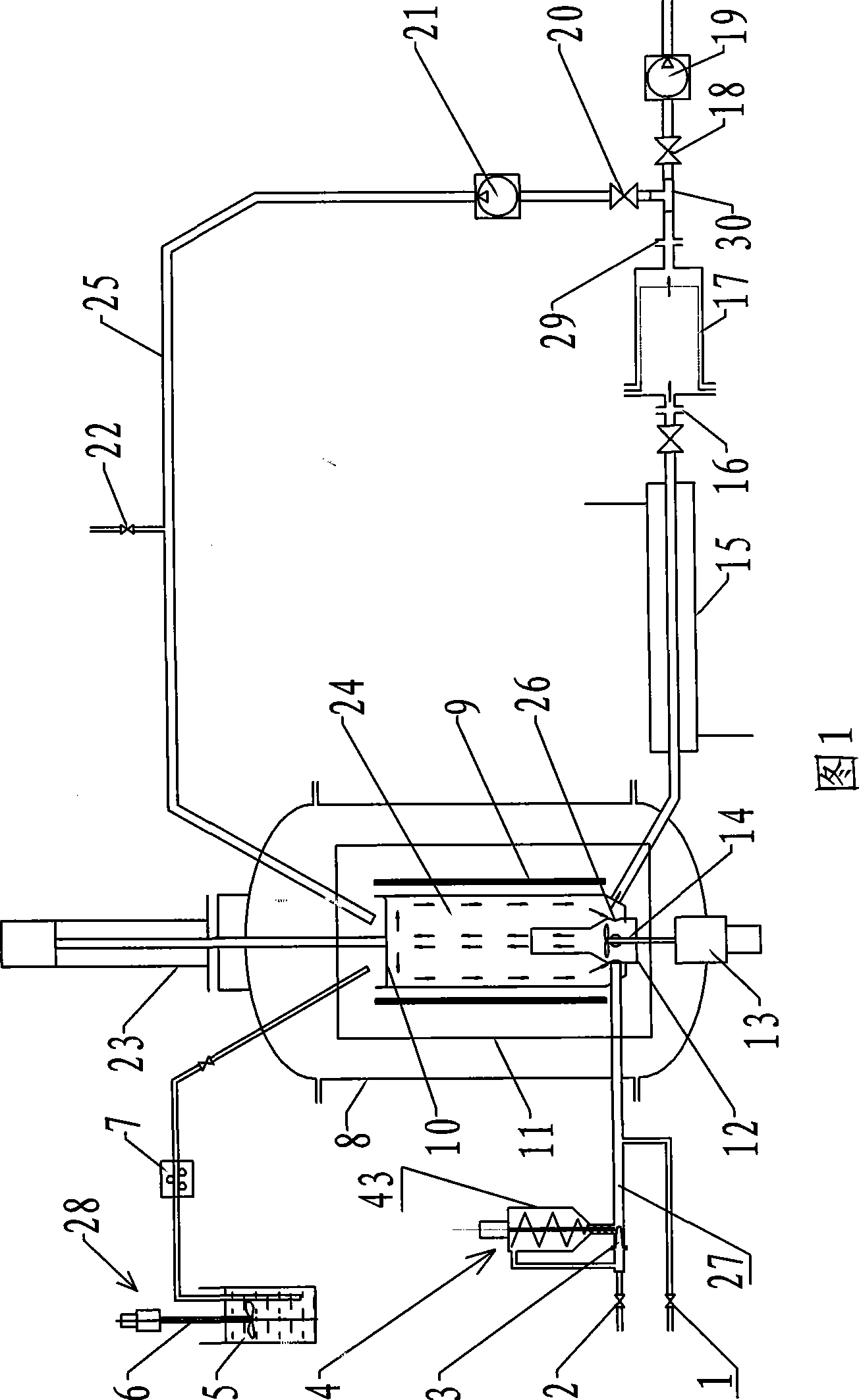

The invention discloses a vertical type reaction device for preparing nanometer carbon fiber in batch. In the reaction device, the periphery of an reaction chamber of a vertical type furnace body is provided with an electric heater and coated with a temperature-preservation layer, the bottom thereof is provided with a water-cool copper rod and the lower part thereof is provided with an air vent; the lower part of the water-cool copper rod is provided with a fan; an air outlet of a main inlet pipe is communicated with a feed delivery pipe of a solid catalyst feeder and connected to the bottom of the reaction chamber; a discharge hole of a liquid catalyst feeder is arranged at the upper end of the reaction chamber and doctor-bars scraped from the reaction product in the reaction chamber canbe arranged at the front end of a piston of a cylinder; a feeding inlet of a cooler is connected to the bottom of the reaction chamber while a feeding outlet is connected with one end of a collector through a valve and a first quick-release coupling; after the other end of the collector passes through a second quick-release coupling, one path is connected with an air inlet of a vacuum pump while the other path is connected with one end of a gas circulator; and one end of a communicating pipe is connected with the other end of the gas circulator while the other end of the communicating pipe isconnected to the top of the reaction chamber. The reaction device improves the productivity of the nanometer carbon fiber greatly and controls the growthform of the nanometer carbon fiber effectively.

Description

Vertical reaction device for preparing nano carbon fibers in batches Technical field The invention relates to chemical equipment, in particular to a reaction device for preparing carbon nanofibers, in particular a device suitable for preparing tubular and solid carbon nanofibers in batches. Background technique Among the methods for preparing carbon nanofibers, the most promising industrialized method is catalytic chemical vapor deposition (CVD), which uses catalysts to crack gaseous hydrocarbons (natural gas, methane, ethylene, acetylene, etc.), and other carbon-containing compounds (CO, methanol, etc.) , Using supported or unsupported iron, cobalt, and nickel as catalysts to prepare carbon nanofibers at appropriate temperatures. The method has the characteristics of simple process, low raw material cost, high output, and the production equipment is also easy to develop. At present, there are no reports on the industrialized equipment for the production of carbon nanofibers i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B31/02

Inventor 唐元洪张勇

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com