Method for producing synthesis gas from hydrocarbon substance-containing slurry

A synthesis gas and crude synthesis gas technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problem of large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

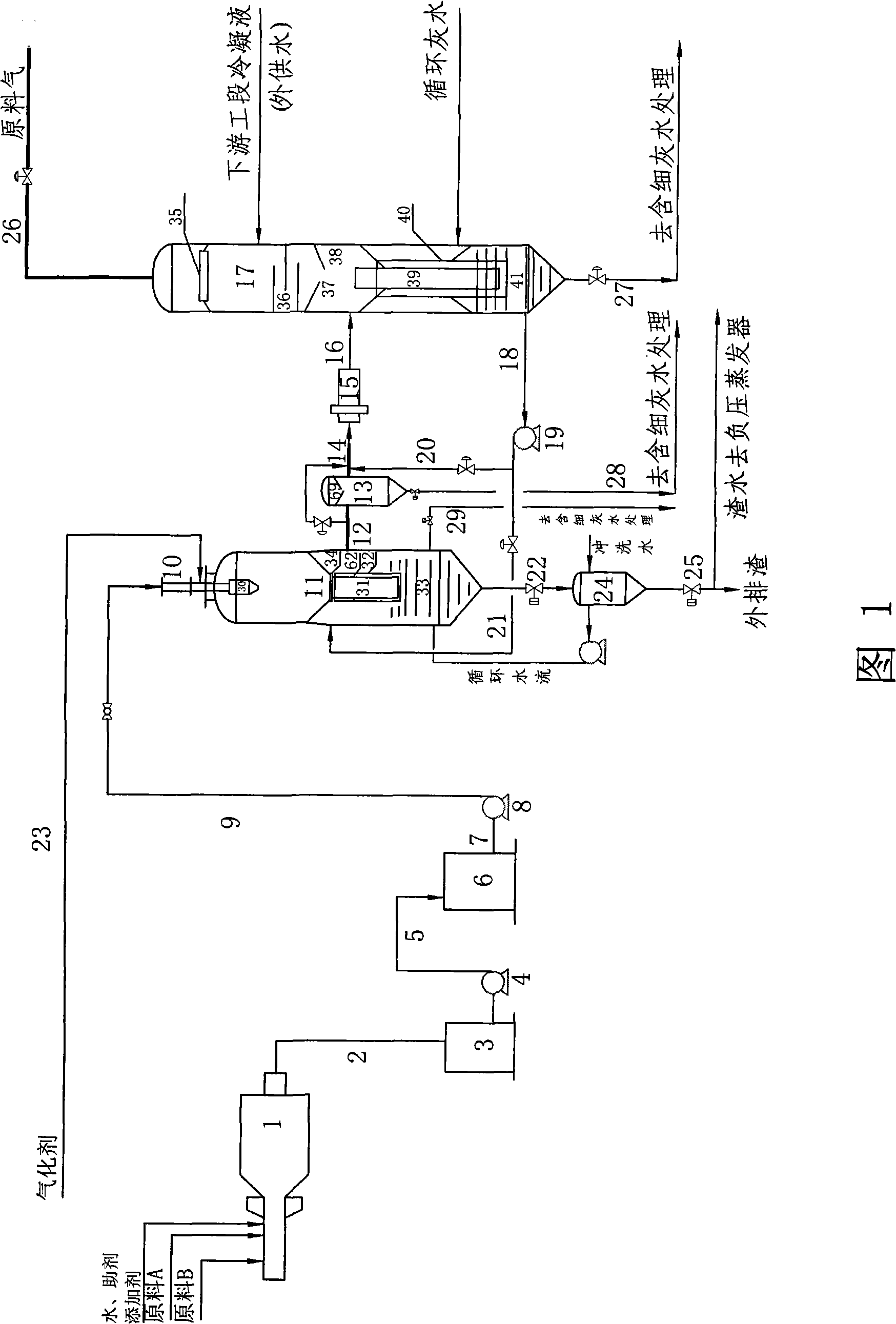

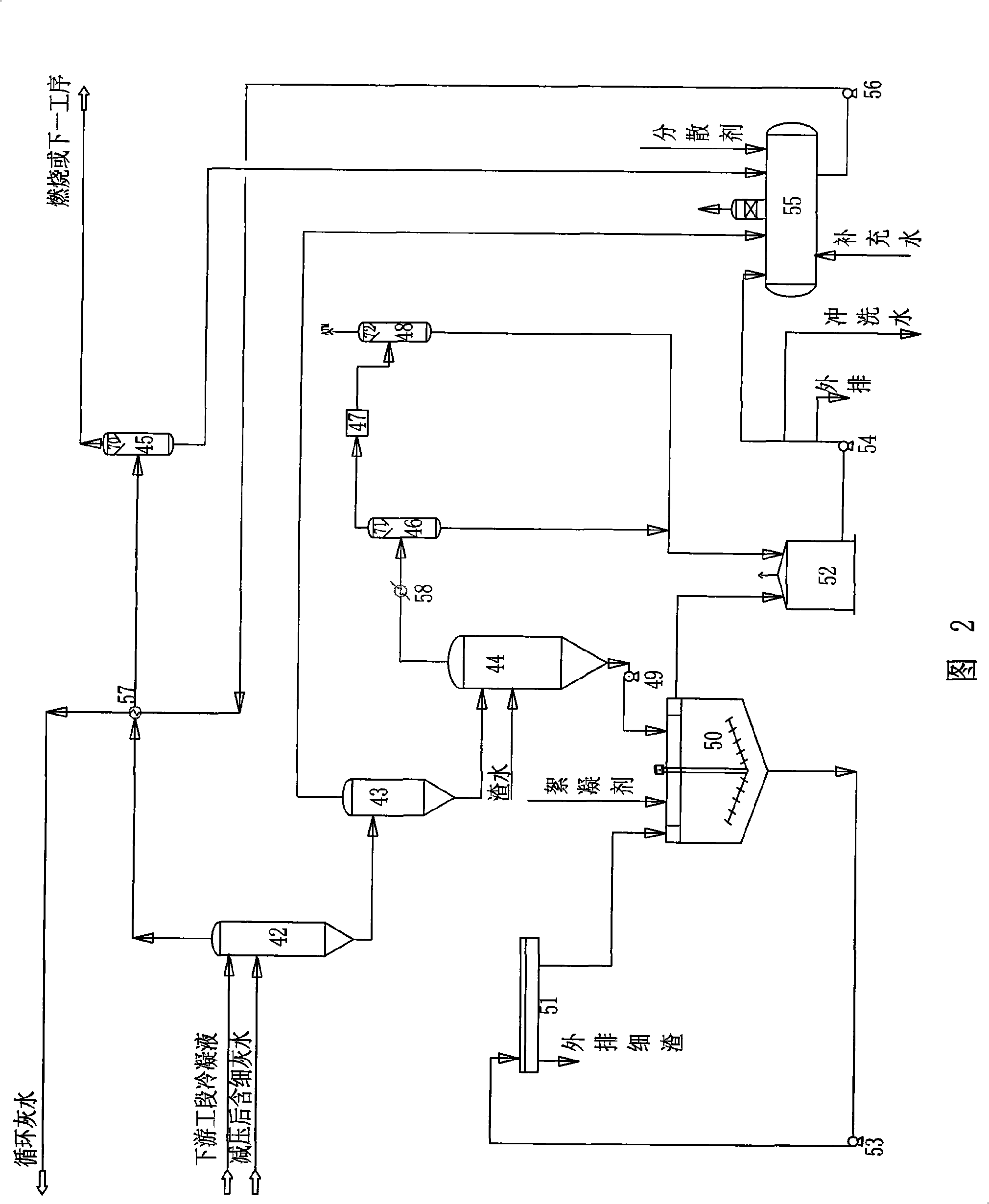

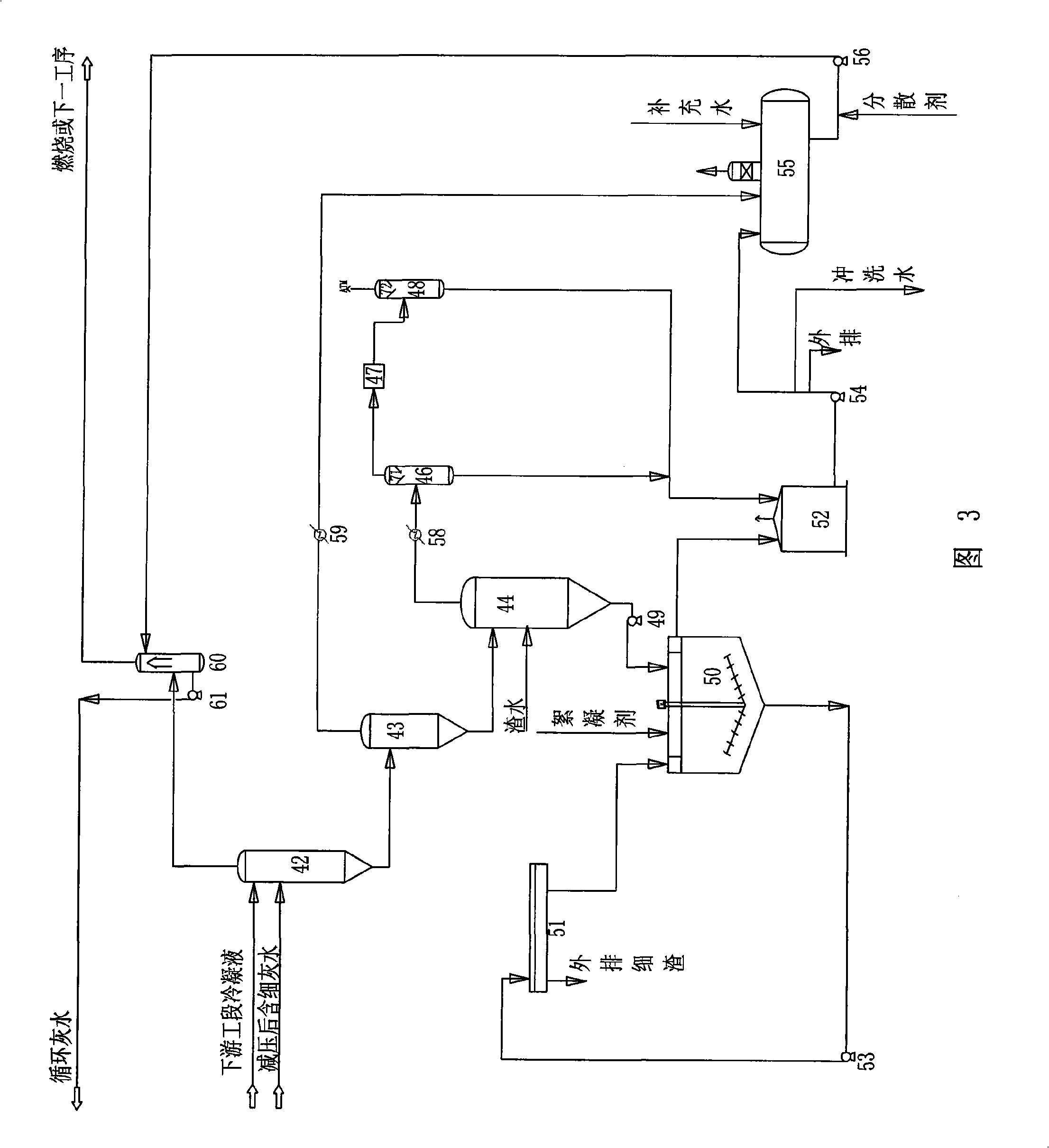

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1: Use Guizhou Dahe coal as a raw material to implement the method of the present invention. The calorific value of the raw material: 26600J / g, the main element analysis results are as follows:

[0083] Yuan

[0084] The operating conditions used are as follows: After the Guizhou Dahe coal is removed with a magnet to remove the iron that may exist in it, the impact crusher produced by Shanghai Yuanhua Machinery Manufacturing Co., Ltd. is used to crush it until the particle size is less than 30mm, and then the coal powder is mixed with water and additives. , auxiliary agent, sent to the rod mill produced by Yate Machinery Manufacturing Co., Ltd., Jiangyin City, Jiangsu Province and carried out a wet co-grinding, the described slurry containing hydrocarbon material slurry concentration 65.0% (weight) is made, wherein the water content 35% (weight), dry coal content 64.64% (weight), sodium lignosulfonate additive content 0.32% (weight), caustic soda c...

Embodiment 2

[0091] Embodiment 2: Use Shenhua coal liquefaction residue as the main raw material to implement the method of the present invention. Calorific value of raw materials: 31580J / g, elemental analysis is as follows:

[0092]

Yuan

white

Minute

analysis

Carbon CAD

Hydrogen Had

Nitrogen Nad

Sulfur St.ad

Oxygen Oad

Fluoride ad

Clad

%(weight)

%(weight)

%(weight)

%(weight)

%(weight)

μg / g

%(weight)

75.78

4.58

0.83

2.34

1.08

70

0.014

[0093] The implementation mode of this embodiment is identical with embodiment 1, just use Shenhua coal liquefaction residue, water, calcium lignosulfonate, caustic soda, the ratio of described Shenhua coal liquefaction residue, water, calcium lignosulfonate, caustic soda is respectively 75.5%, 24.0%, 0.3%, 0.2% in terms of its total material weight, mak...

Embodiment 3

[0096] Embodiment 3: The method of the present invention is carried out with the mixture of Shenfu coal accounting for 2 / 3 and petroleum coke accounting for 1 / 3 as the main raw material. Calorific value of this raw material: 28976J / g, elemental analysis is as follows:

[0097]

Yuan

white

Minute

analysis

Carbon CAD

Hydrogen Had

Nitrogen Nad

Sulfur St.ad

Oxygen Oad

Fluoride ad

Clad

%(weight)

%(weight)

%(weight)

%(weight)

%(weight)

μg / g

%(weight)

70.02

4.07

0.91

0.4

9.2

68

0.015

[0098] The implementation mode of this example is the same as the process of Example 1, except that the pressure of the entrained-bed coal gasification reactor 11 is different for internal heat preservation, and the raw materials used are different. Use Shenfu coal weight to account for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com