Coordinates platform for accurately locating three-dimensional laser cutting part

A three-dimensional laser, precise positioning technology, used in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of time-consuming and laborious, unable to obtain satisfactory results, and difficult to accurately position parts, and achieve good portability. , convenient positioning and programming work, convenient and effective positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

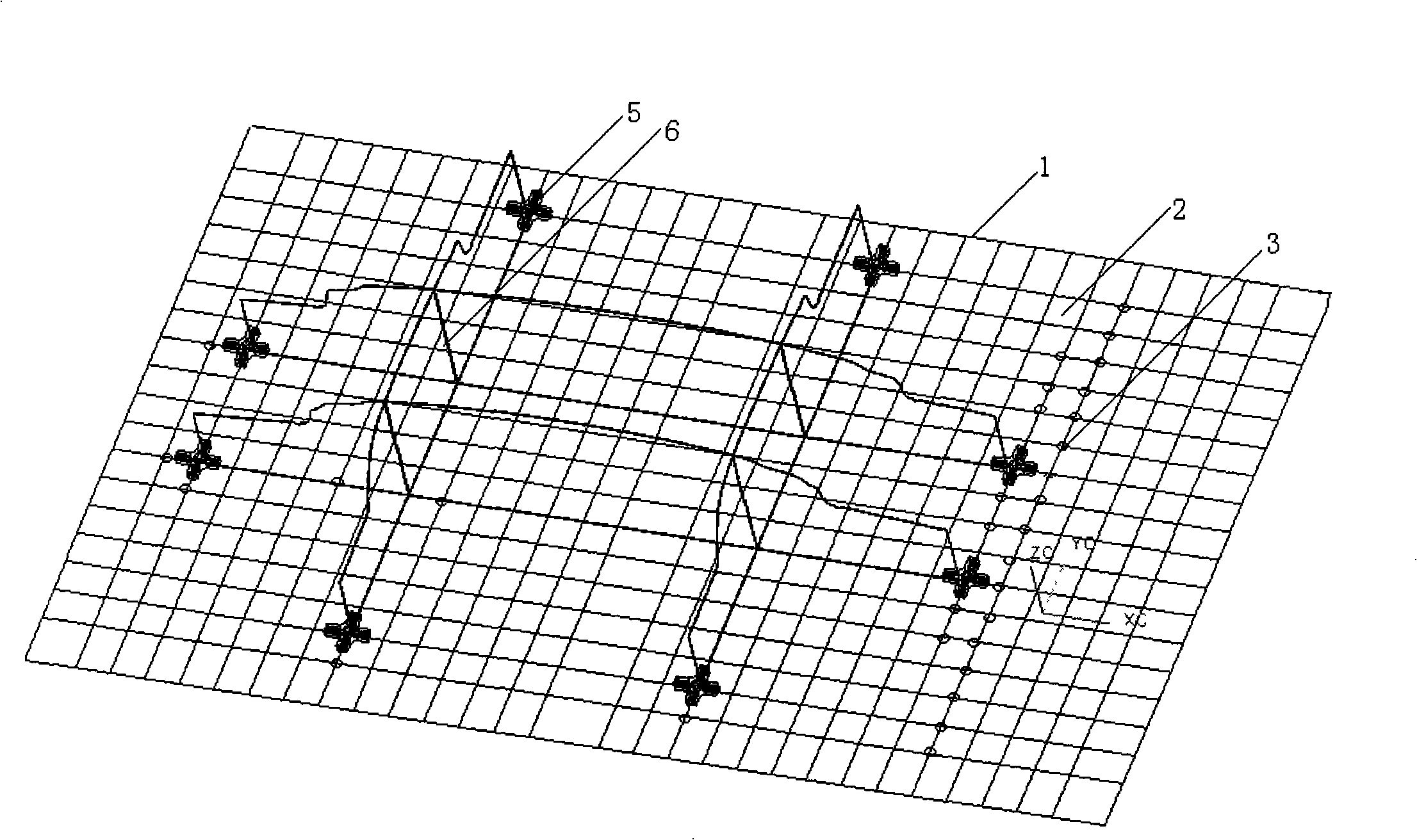

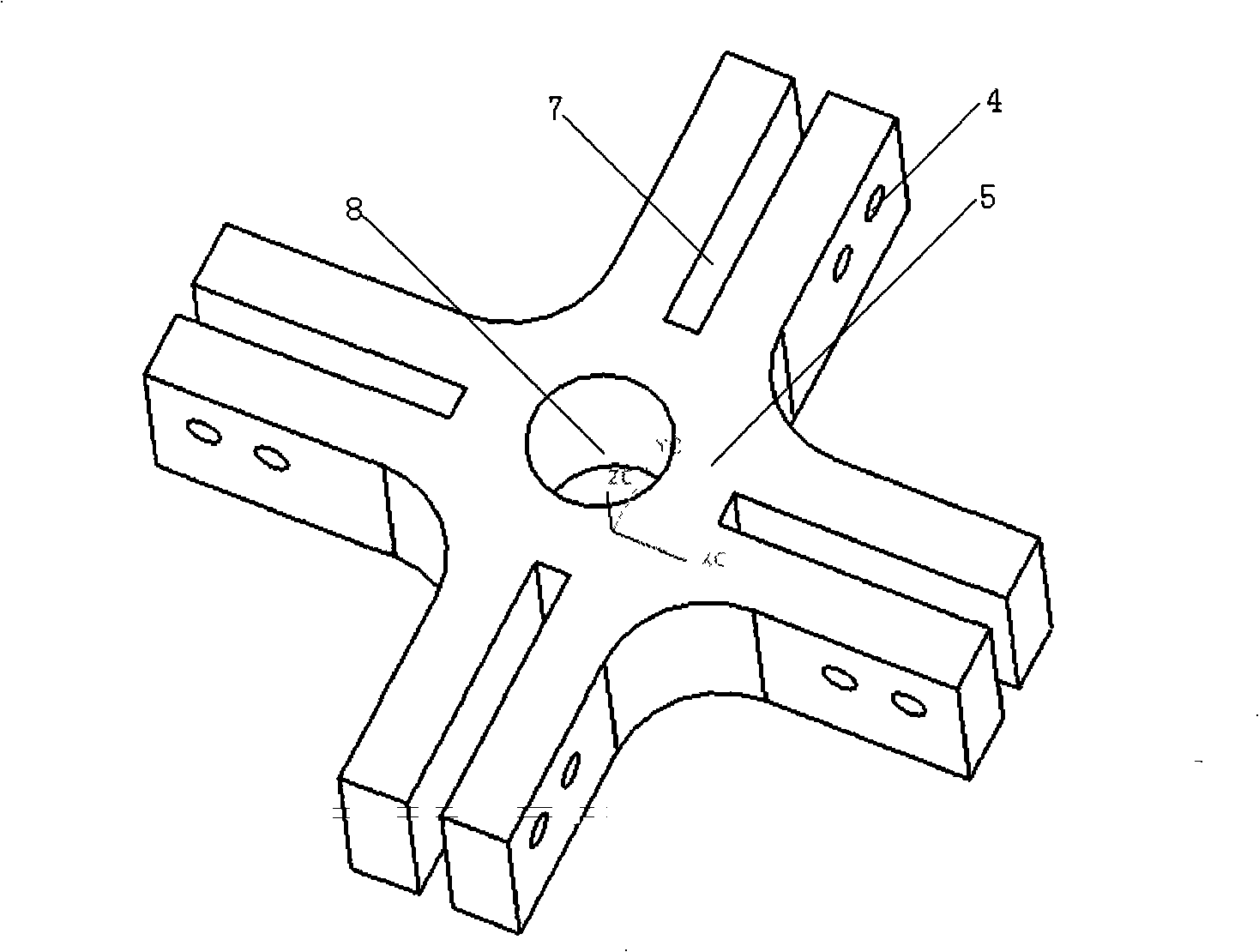

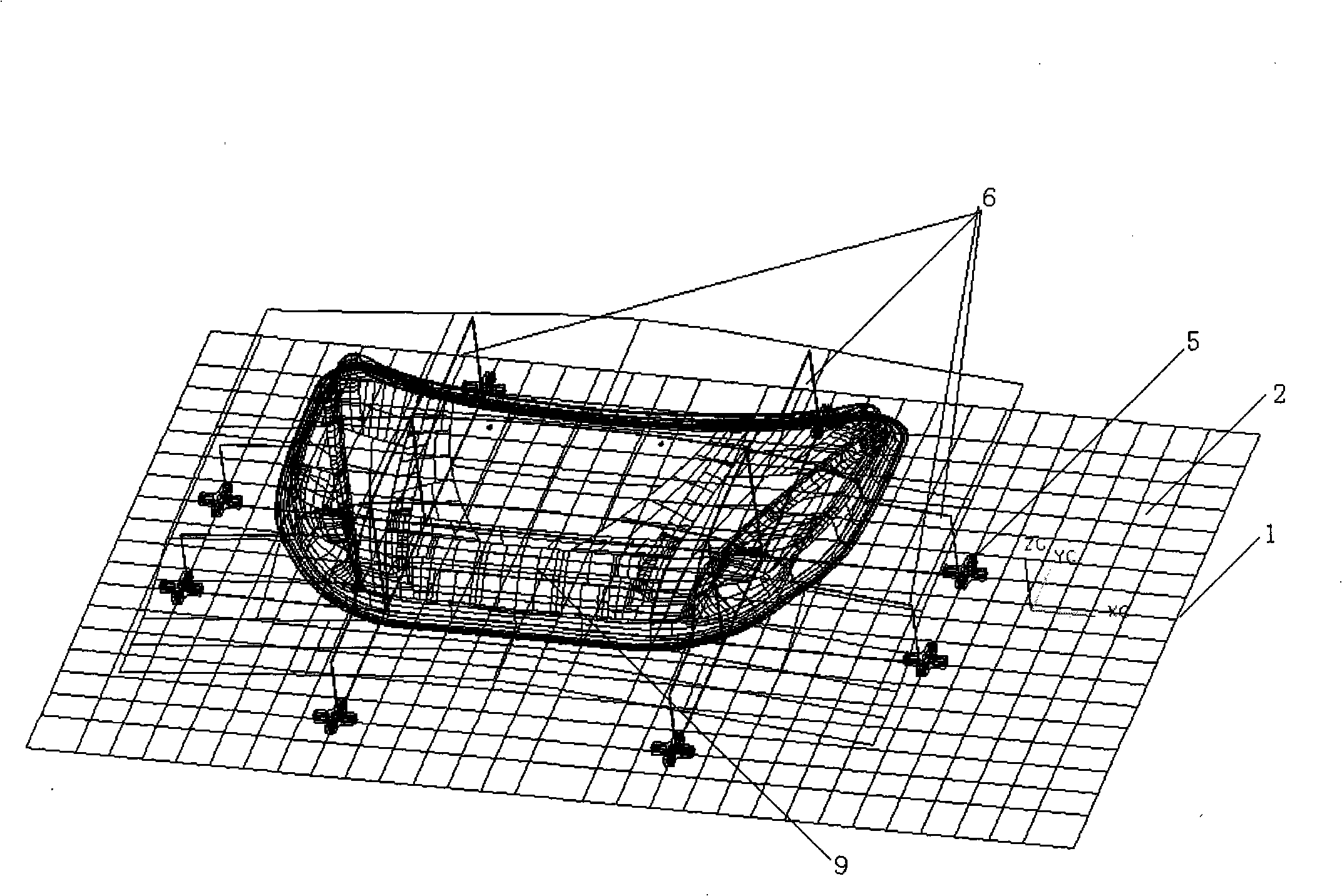

[0011] refer to figure 1 . The positioning base plate 1 shown in the figure can be placed on the TDLC-04R laser cutting machine tool, and its shape is the same as the table top of NTC's TDLC-04R 5-axis three-dimensional laser cutting machine tool. The positioning base plate 1 is fixed on the machine tool table by corresponding several hexagon socket screws. The thickness of the positioning bottom plate is 15mm, and it can be composed of two rigid plates with a total weight of about one ton, which will not affect the operation of the machine tool and are easy to hoist. A rectangular coordinate grid 2 arranged equidistantly is arranged on the table top of the positioning base plate 1 in the length and width direction. The side length of the rectangle of the coordinate grid 2 may be a square with a side length of 50 mm or 100 mm. Positioning threaded holes 3 are formed at the intersection of the coordinate grids, (for a concise drawing, only the arrangement of some holes is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com