Environmental-protecting type high-efficient cleaning system

A cleaning system and an environment-friendly technology, applied in the cleaning field, can solve the problems of high cost of dry ice processing, environmental pollution by chemical cleaning, and easy to be affected by gasification, and achieve the effect of preventing splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings.

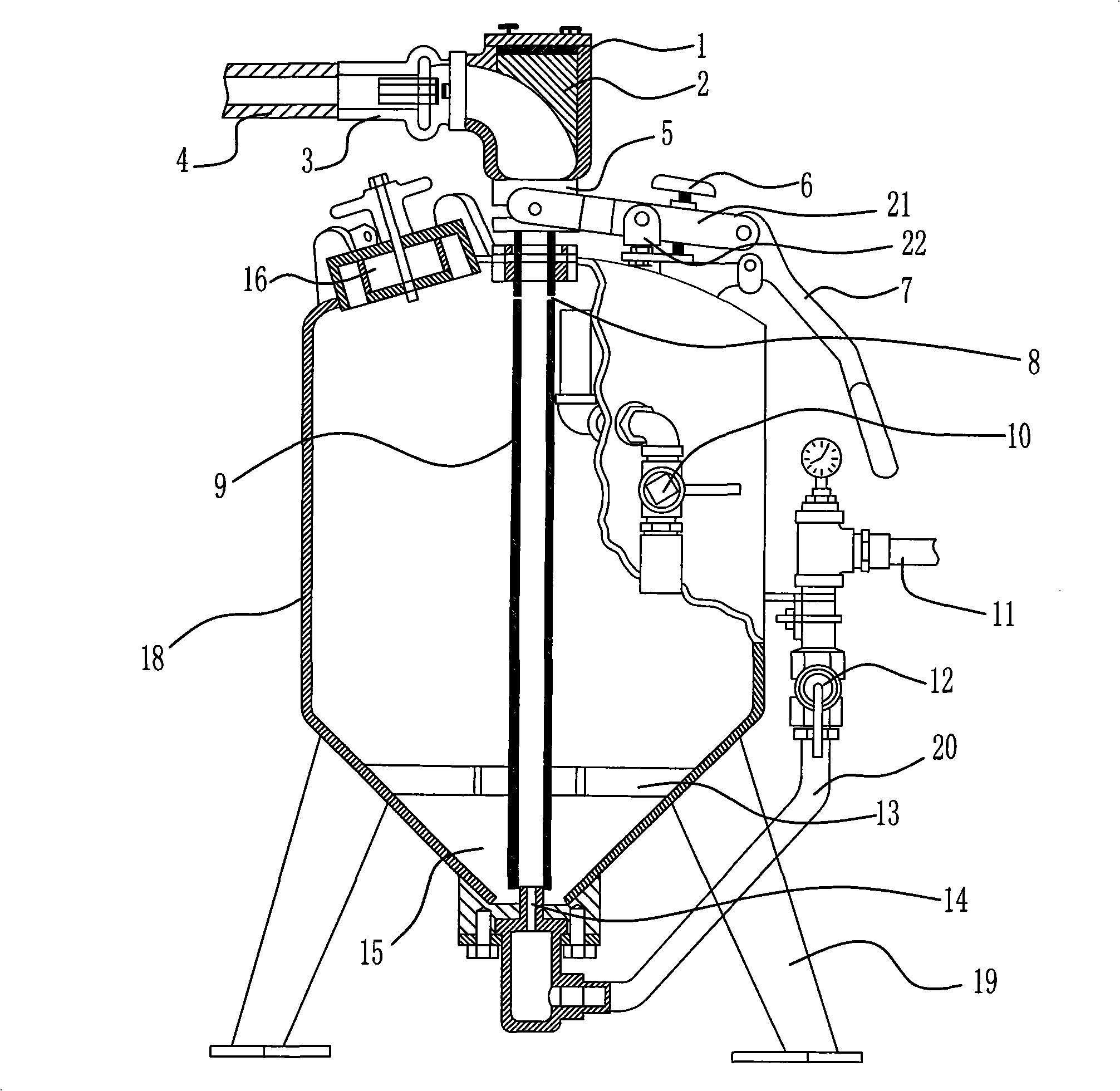

[0043]Cleaning system of the present invention comprises dry explosion cleaning host (see figure 1 ), an air compressor, an air storage tank and a water source, and the tank body 18 communicates with the water source. The improvement of the present invention mainly lies in the dry explosion cleaning host, and the dry explosion cleaning host will be described in detail below.

[0044] Such as figure 1 As shown, the dry explosion cleaning host includes a tank body 18, the bottom outer wall of the tank body 18 is supported by a foot 19, and the bottom center of the tank body 18 is sealed with an air input nozzle 14, and the nozzle 14 is made of wear-resistant hardened steel. The upper opening of the nozzle 14 communicates with the inside of the tank body 18 , and the lower opening passes through the pipeline 20 , the compressed air input control valve 12 and the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com