Synthetic method of superficially pellicular packing stuffing for strong-acid cation chromatographic column and product

A technology of strong acid cation and synthesis method, which is applied in the field of synthesizing filler for surface thin-shell type strong acid cation chromatographic column, can solve the problems of poor resistance to organic solvents, easy cracking of resin, and high sulfonation temperature, and achieves resistance to The effect of good organic solvent performance, strong organic solvent resistance performance and low sulfonation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

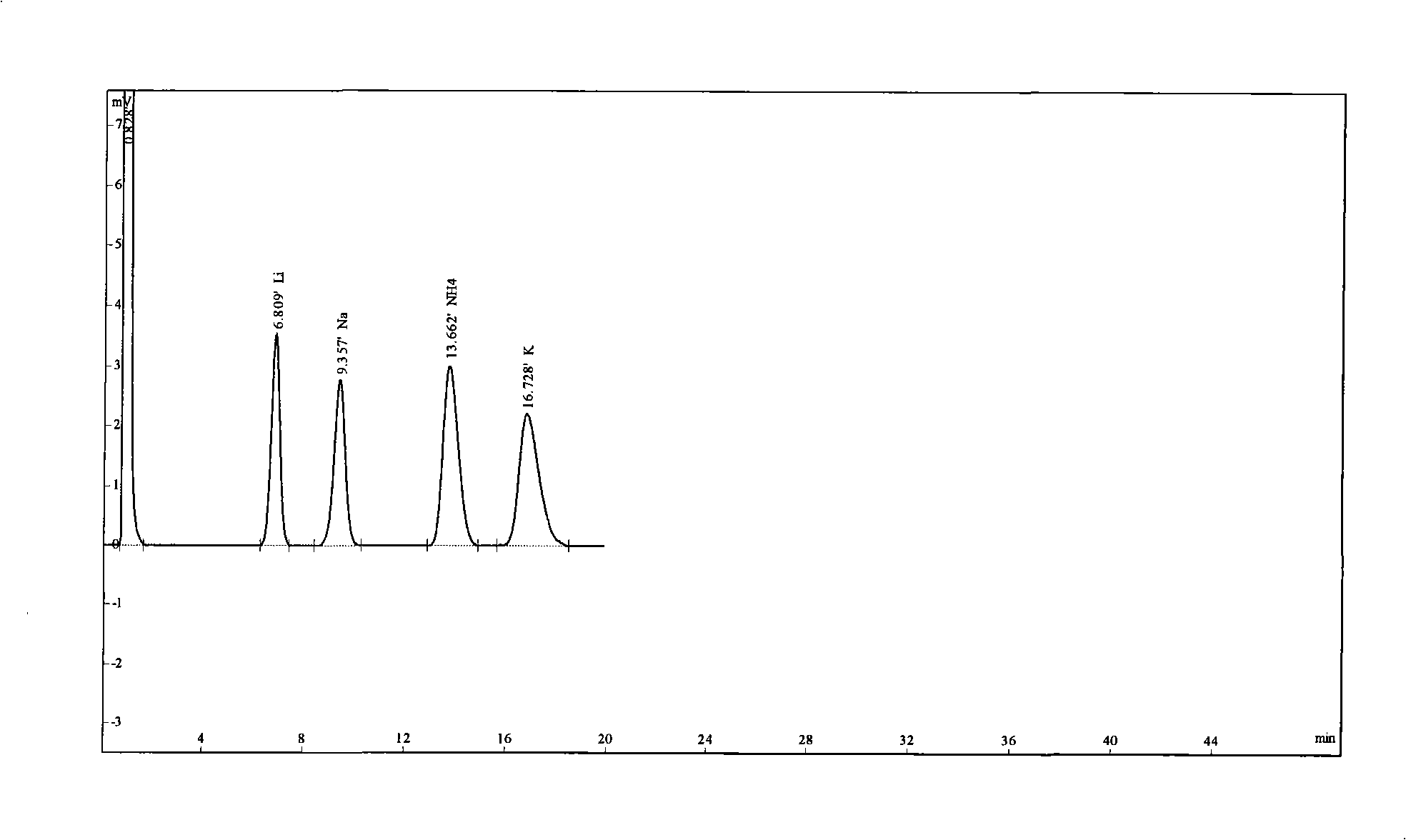

Image

Examples

Embodiment 1

[0017] 1. Two-step dispersion polymerization and swelling method to synthesize monodisperse spherical styrene-divinylbenzene resin with a particle size of 12um and a crosslinking degree of 10%.

[0018] 2. Low temperature sulfonation

[0019] Functionalization of monodisperse spherical styrene-divinylbenzene resin microspheres with a particle size of 12 μm and a crosslinking degree of 10%, that is, low-temperature sulfonation

[0020] Get 10 g of the monodisperse spherical styrene-divinylbenzene resin microspheres with a particle size of 12 μm and a crosslinking degree of 10% obtained above, and add it to a 250 ml three-necked flask equipped with a stirrer, an addition funnel and a reflux condenser, and add 100ml dichloroethane, start the stirrer to stir. Take 10ml of chlorosulfonic acid, dissolve it in 100ml of dichloromethane, add it to the addition funnel, place the whole device in an ice-water bath, slowly add dichloromethane dissolved in chlorosulfonic acid dropwise, aft...

Embodiment 2

[0027] The difference between the synthesis process and Example 1 lies in the low-temperature sulfonation step: Weigh 10 g of monodisperse spherical styrene-divinylbenzene resin microspheres with a particle size of 12 μm and a crosslinking degree of 10% into a 250 ml flask equipped with a stirrer Add 100ml of concentrated sulfuric acid, under slow stirring, heat up to 30°C, keep warm for 15 minutes, take out and quickly pour the reactant into deionized water in a large amount of ice-water bath to terminate the reaction, filter and wash the reactant, and then evenly Slurry column packing.

Embodiment 3

[0029] The difference between the synthesis process and Example 1 is that 1. a styrene-divinylbenzene resin with a crosslinking degree of 6% and a particle size of 30 μm is synthesized by suspension polymerization;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com