Method for preparing silver and titanic oxide nano compound material at low temperature

A nano-composite material, titanium dioxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., to achieve simple preparation methods and excellent photocatalysis effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Dissolving butyl titanate in ethanol, the molar ratio of butyl titanate to ethanol is 1:6, to obtain liquid A;

[0018] 2) Drop A solution into water, the molar ratio of water to butyl titanate is 40, adjust the pH value of the solution to 3 with nitric acid, stir until a stable sol is formed, and obtain B solution;

[0019] 3) dissolving silver nitrate and an equivalent amount of diethanolamine in ethanol to obtain liquid C, the molar ratio of ethanol to silver nitrate is 12, and the molar ratio of silver nitrate to butyl titanate is 0.1;

[0020] 4) Mix liquid C and liquid B, dry at 50°C after aging, and obtain silver and titanium dioxide nanocomposite material.

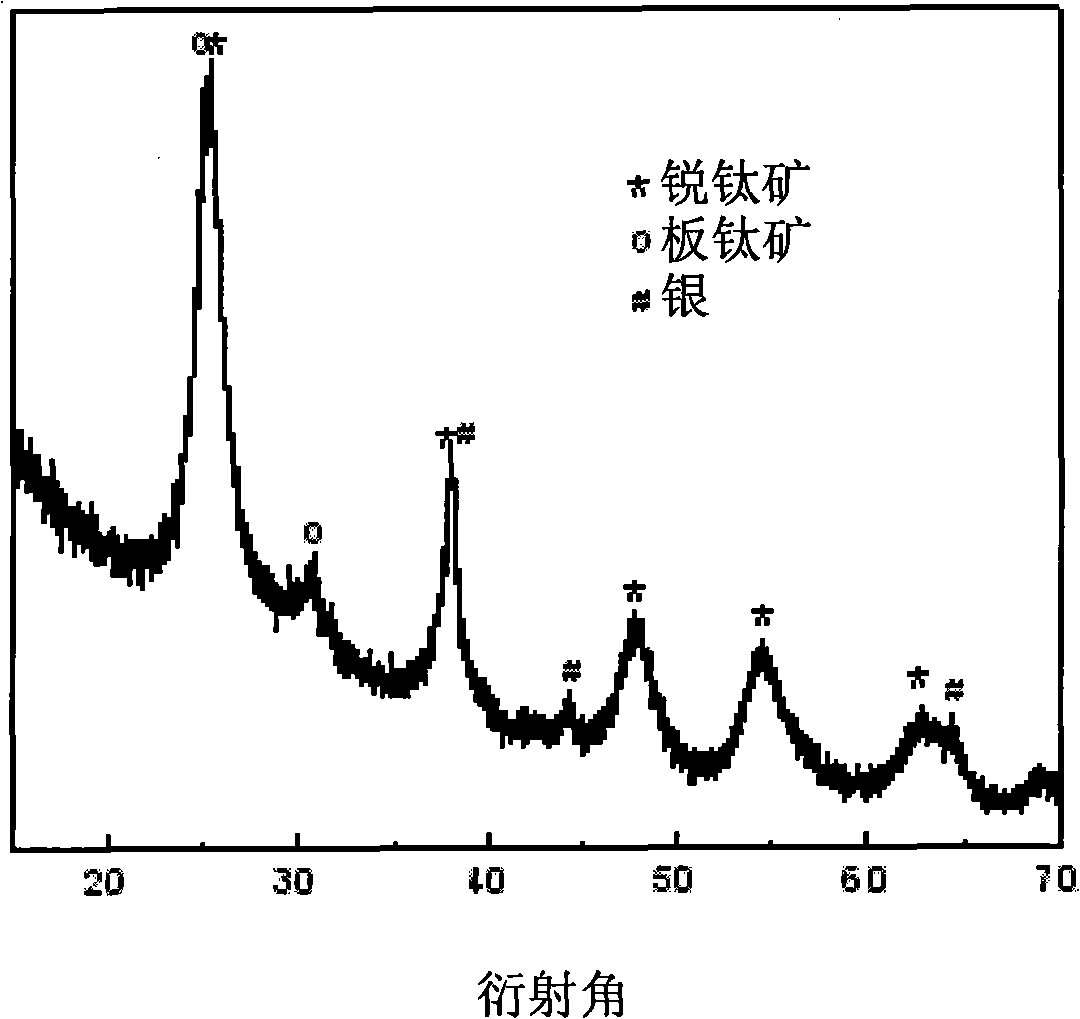

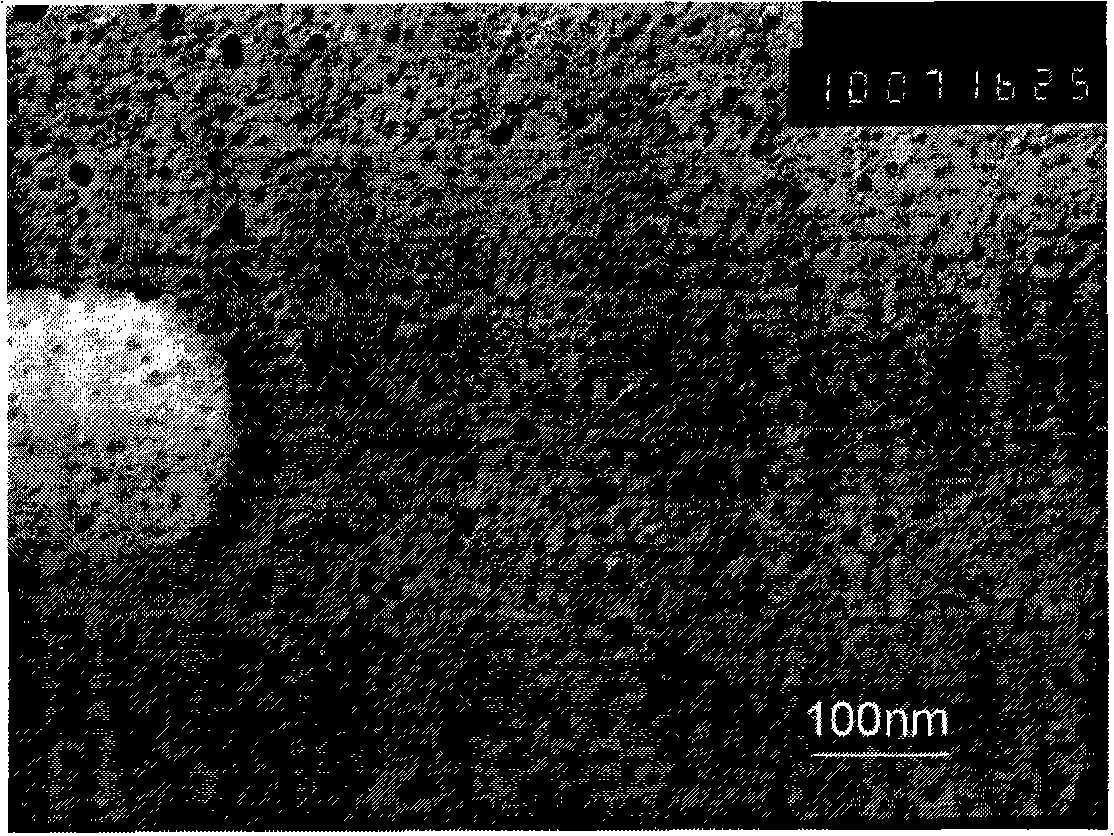

[0021] The X-ray diffraction patterns of the prepared silver and titanium dioxide nanocomposites are as follows: figure 1 As shown, titanium dioxide is composed of anatase and brookite, and silver exists as zero-valent silver with a face-centered cubic structure. The transmission electron micrographs of...

Embodiment 2

[0023] 1) Dissolving isopropyl titanate in ethylene glycol, the molar ratio of isopropyl titanate to ethylene glycol is 1:5, to obtain liquid A;

[0024] 2) Drop A liquid into water drop by drop, the molar ratio of water to isopropyl titanate is 100, adjust the pH value of the solution to 2 with nitric acid, stir until a stable sol is formed, and obtain B liquid;

[0025] 3) Silver nitrate and diethanolamine are dissolved in ethylene glycol at a molar ratio of 1:4 to obtain liquid C. The molar ratio of ethylene glycol to silver nitrate is 10, and the molar ratio of silver nitrate to isopropyl titanate is 0.001;

[0026] 4) Mix liquid C and liquid B, dry at 100° C. after aging, and obtain a nanocomposite material of silver and titanium dioxide.

[0027] The obtained titanium dioxide crystals have a size of about 6 nanometers, and the silver particles have a size of 4-10 nanometers.

Embodiment 3

[0029] 1) Dissolving titanium chloride in propanol, the molar ratio of titanium chloride and propanol is 1:10, to obtain liquid A;

[0030] 2) Drop A liquid into water drop by drop, the molar ratio of water to titanium chloride is 200, adjust the pH value of the solution to 4 with hydrochloric acid, stir until a stable sol is formed, and obtain B liquid;

[0031] 3) Dissolve silver chloride and diethanolamine in propanol at a molar ratio of 1:8 to obtain liquid C. The molar ratio of propanol to silver chloride is 20, and the molar ratio of silver chloride to titanium chloride is 0.3 ;

[0032] 4) Mix liquid C and liquid B, dry at 150°C after aging, and obtain silver and titanium dioxide nanocomposite material.

[0033] The obtained titanium dioxide crystals have a size of about 4 nanometers, and the silver particles have a size of 15-40 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com