Multi-wavelength laser, its production method and use

A technology of multi-wavelength lasers and lasers, applied in lasers, laser components, semiconductor lasers, etc., can solve the problems of low output power, poor wavelength selectivity, and high difficulty in integrating multi-wavelength lasers, and achieve high output optical power and wavelength selectivity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. For the sake of clarity and simplicity, detailed detailed descriptions of known functions and constructions in the devices described herein will be omitted when it may obscure the subject matter of the present invention.

[0035] First, the multi-wavelength laser described in the embodiment of the present invention will be described in detail with reference to the accompanying drawings.

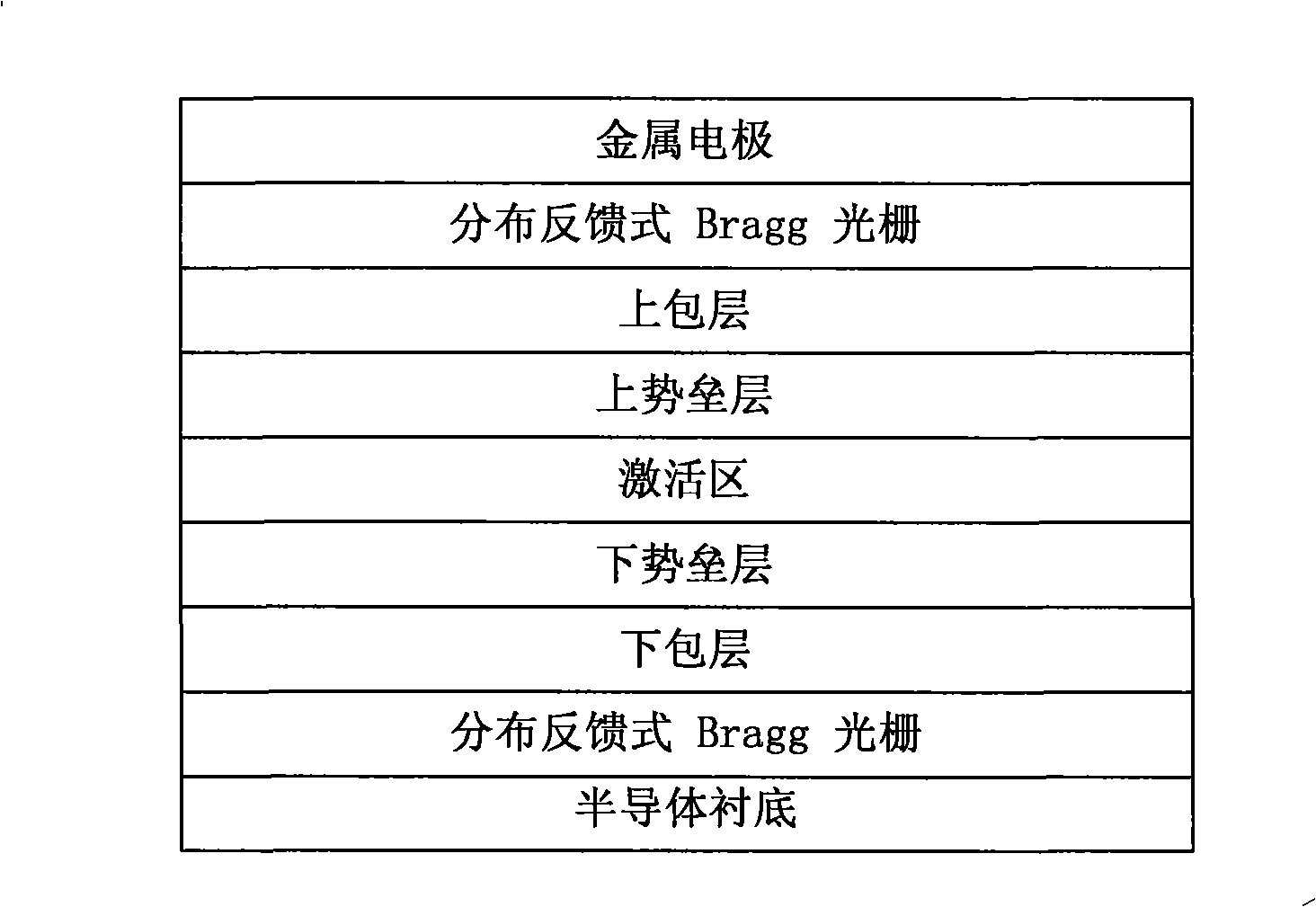

[0036] Such as figure 1 as shown, figure 1 Shown is a schematic diagram of the structure of a multi-wavelength laser based on the quantum confinement effect in an embodiment of the present invention. The multi-wavelength laser includes at least: a packaging substrate, a thermoelectric cooler, a substrate, a carrier, and a laser chip, etc., wherein the packaging substrate and thermoelectric The cooler is fixed together by solder, the thermoelectric cooler and subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com