Laser gas analyzer and its calibration method

A laser gas and analyzer technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of instrument measurement error, increased labor intensity, and large consumption, avoiding measurement errors, high sensitivity and accuracy, and low application cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

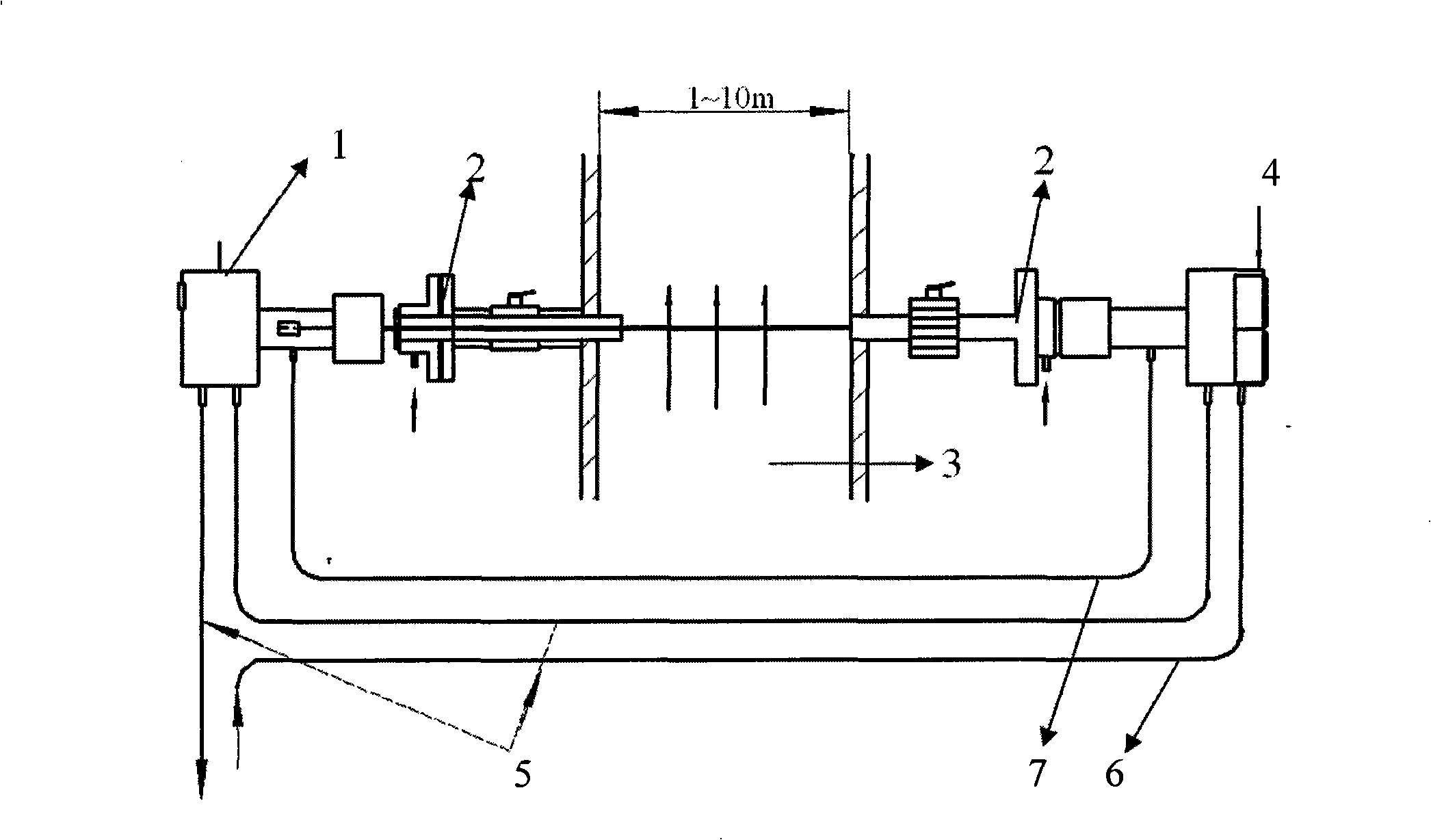

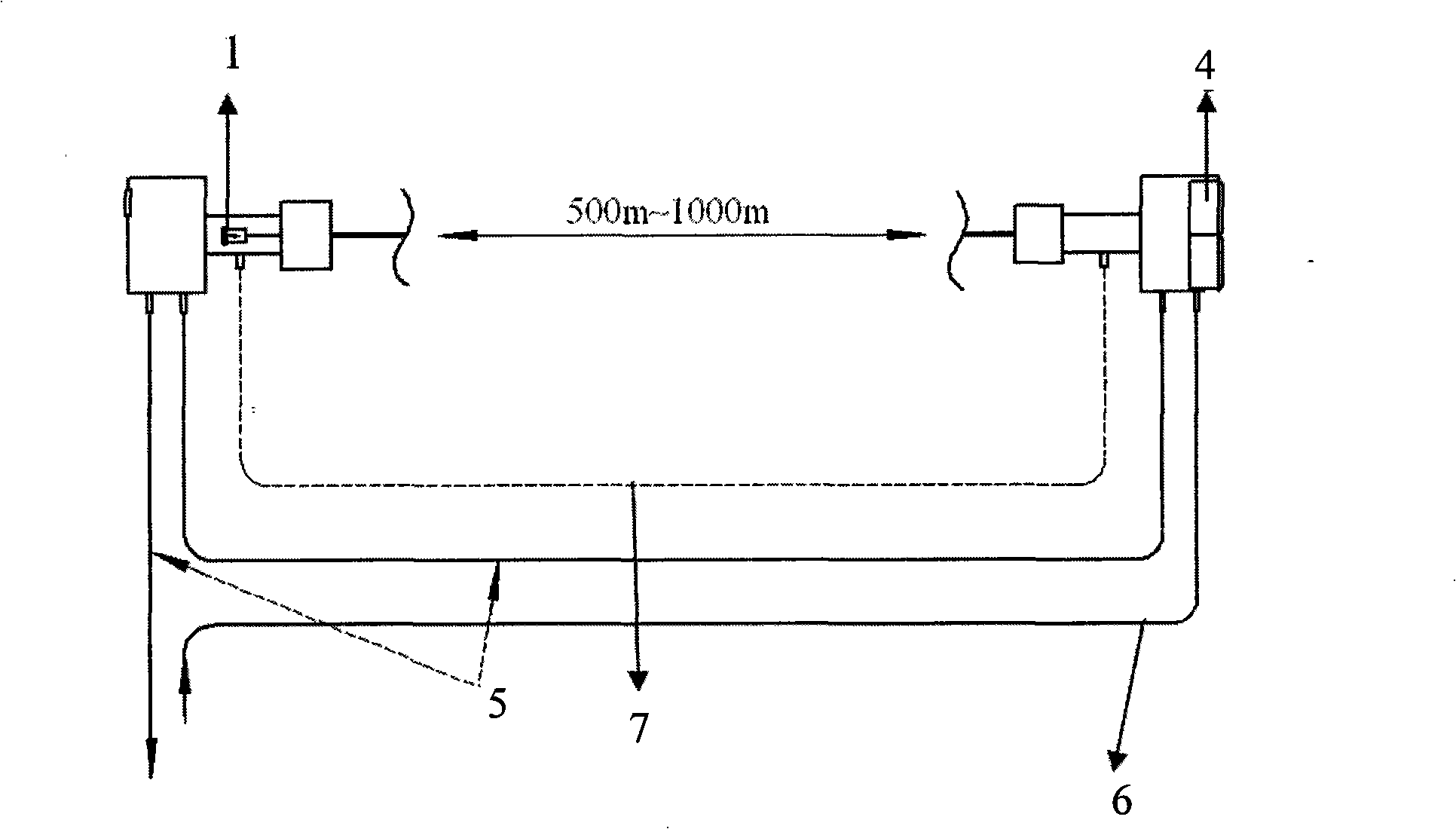

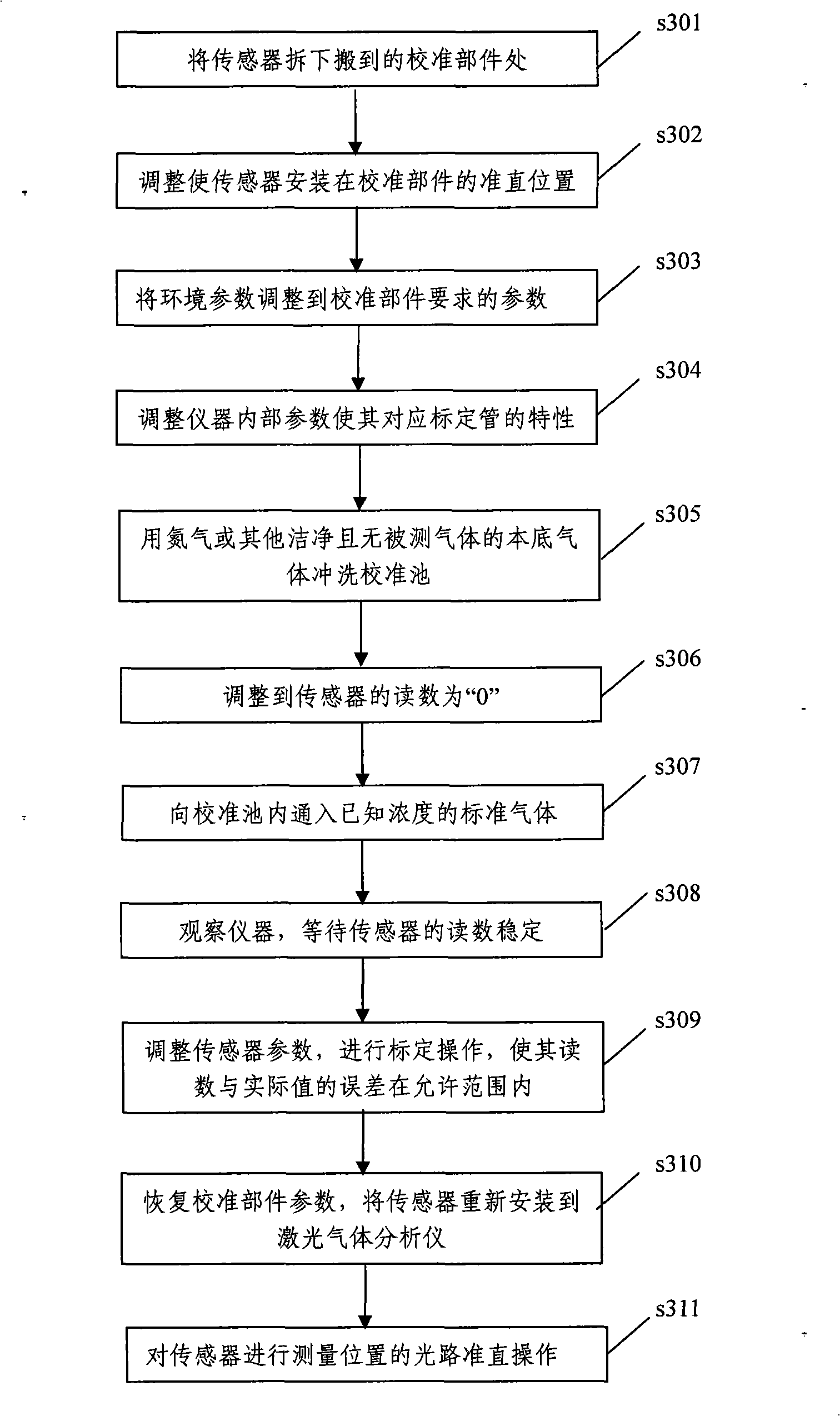

[0068] As shown in Figure 5, it is the optical path structure diagram of the laser gas analyzer of this embodiment. The optical path structure adopts a composite optical path structure, and the composite structure refers to: firstly, the measuring pool 13 adopts reflectors to reflect the measuring beam multiple times to increase the effective measuring optical path. Secondly, in order to obtain the light energy change data at several key points in the light path, the multi-channel beam splitting technology is used for the final photometric calculation. In this embodiment, the light source radiation unit 1 includes a laser light source driving circuit 101 and a semiconductor light source element 102, and the driving circuit 101 provides the current and voltage required by the light source 102 to make it produce a laser beam; in this embodiment, the measuring pool 13 and the reference The pools 12 are all sealed cubes, and the pool body of the measuring pool 13 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com