Calibration apparatus and method for ultra-high pressure safety valve

A calibration method and calibration device technology, which is applied in the direction of measuring devices, testing of machines/structural components, and by measuring the rate of increase and deceleration of fluids, etc., can solve the problem of purchasing extra valves, affecting the safety of use and normal production, and safety valves Performance changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

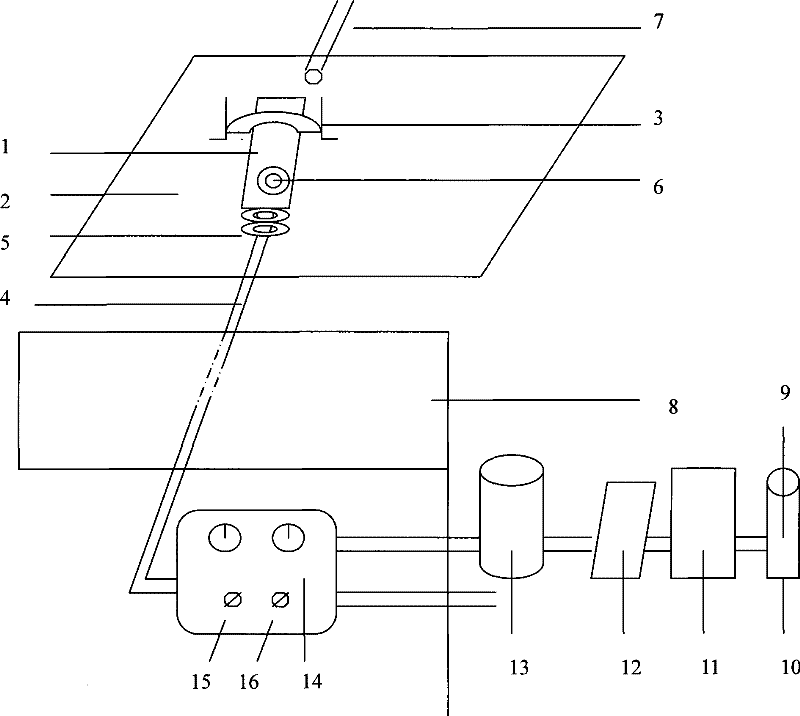

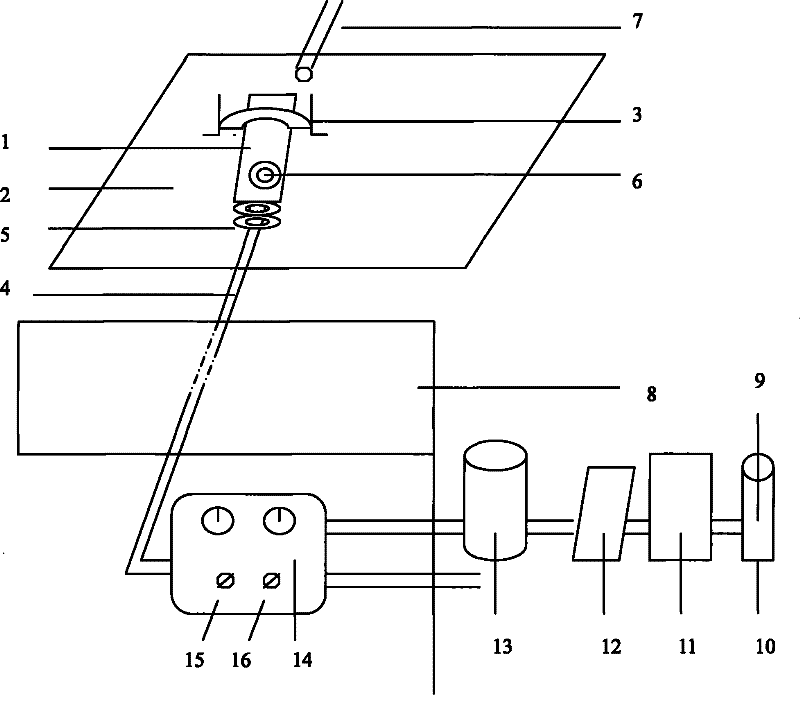

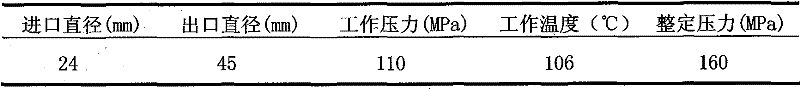

[0051] Embodiment 1, the verification device of the ultra-high pressure safety valve, its structure and connection are as follows:

[0052] The ultra-high pressure safety valve 1 is lying on the working platform 2, with the outlet flange facing upward, and the ultra-high pressure safety valve 1 is fixed on the working platform 2 with ordinary U-shaped bolts 3, and the ultra-high pressure safety valve 5 and the ultra-high pressure safety valve 1 are used Bolt connection, one end of the ultra-high pressure pipe 4 is threadedly connected with the ultra-high pressure flange 5, and the other end passes through the safety protection wall 8 and is connected with the console 14. The console 14 is equipped with a booster valve 15 and a pressure relief valve 16. One side of the energy device 13 is connected to the console 14 through the ultrahigh pressure pipe 4, and the other side is connected to the ultrahigh pressure pump 12 through the ultrahigh pressure pipe 4. The gas source 9 for ...

Embodiment 2

[0059] Embodiment 2, using the verification device of the above ultra-high pressure safety valve to carry out the verification method of the ultra-high pressure safety valve, the method steps are as follows:

[0060] 1. Clean and decontaminate the inlet and outlet of the ultra-high pressure safety valve 1 to be verified with acetone before connecting;

[0061] 2. Macroscopically inspect the ultra-high pressure safety valve 1. All parts must be in good condition without cracks, inner cavity corrosion and mechanical damage;

[0062] 3. Inject pure water 6 into the valve cavity from the outlet flange of ultra-high pressure safety valve 1, and drain the air bubbles inside the valve cavity after standing still for 5-8 minutes;

[0063] 4. Build the safety protection wall 8 to isolate the calibration equipment area from the manual operation area. The operator operates outside the safety protection wall 8 and observes through the observation screen of the video surveillance equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com