Apparatus for measuring combustion chamber flue gas temperature by utilizing acoustics

A furnace flue gas and acoustic technology, used in measuring devices, thermometers with physical/chemical changes, thermometers, etc., can solve problems such as large errors, unstable measurement results, and inability to accurately measure for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

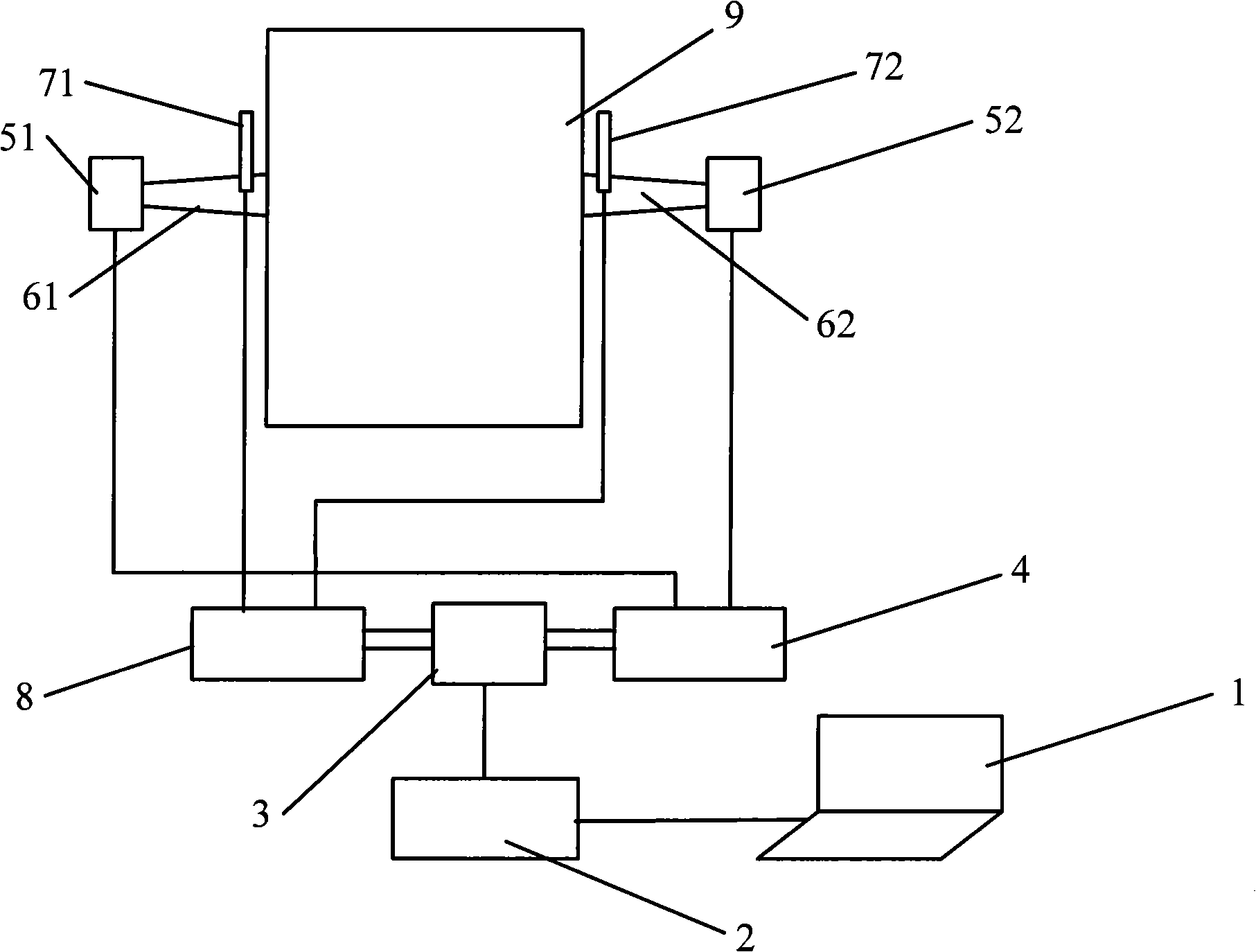

[0016] The present invention provides a device for measuring the flue gas temperature of a furnace by means of acoustics, and the present invention will be further described below through the description of the drawings and specific implementation methods.

[0017] figure 1 It is a structural schematic diagram of the flue gas temperature measuring device of the present invention. The left acoustic waveguide 61 and the right acoustic waveguide 62 are respectively installed at symmetrical positions above the middle part of the furnace wall side wall of the furnace 9. The left acoustic waveguide 61 and the right acoustic waveguide 62 adopt conical horns, and the acoustic impedance changes uniformly near the cutoff frequency and has strong directivity. , to facilitate the rectilinear propagation of sound waves; the end of the left acoustic waveguide 61 is connected to the left dynamic speaker 51, the left enhanced microphone 71 is installed on the upper end of the left acoustic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com