Down-hole tool and controllable segment sealing device for down-hole working barrel seal

A technology of sealing device and work cylinder, which is applied in the field of pressure sealing, can solve the problems of unable to monitor pressure and large external dimensions, achieve high application value and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

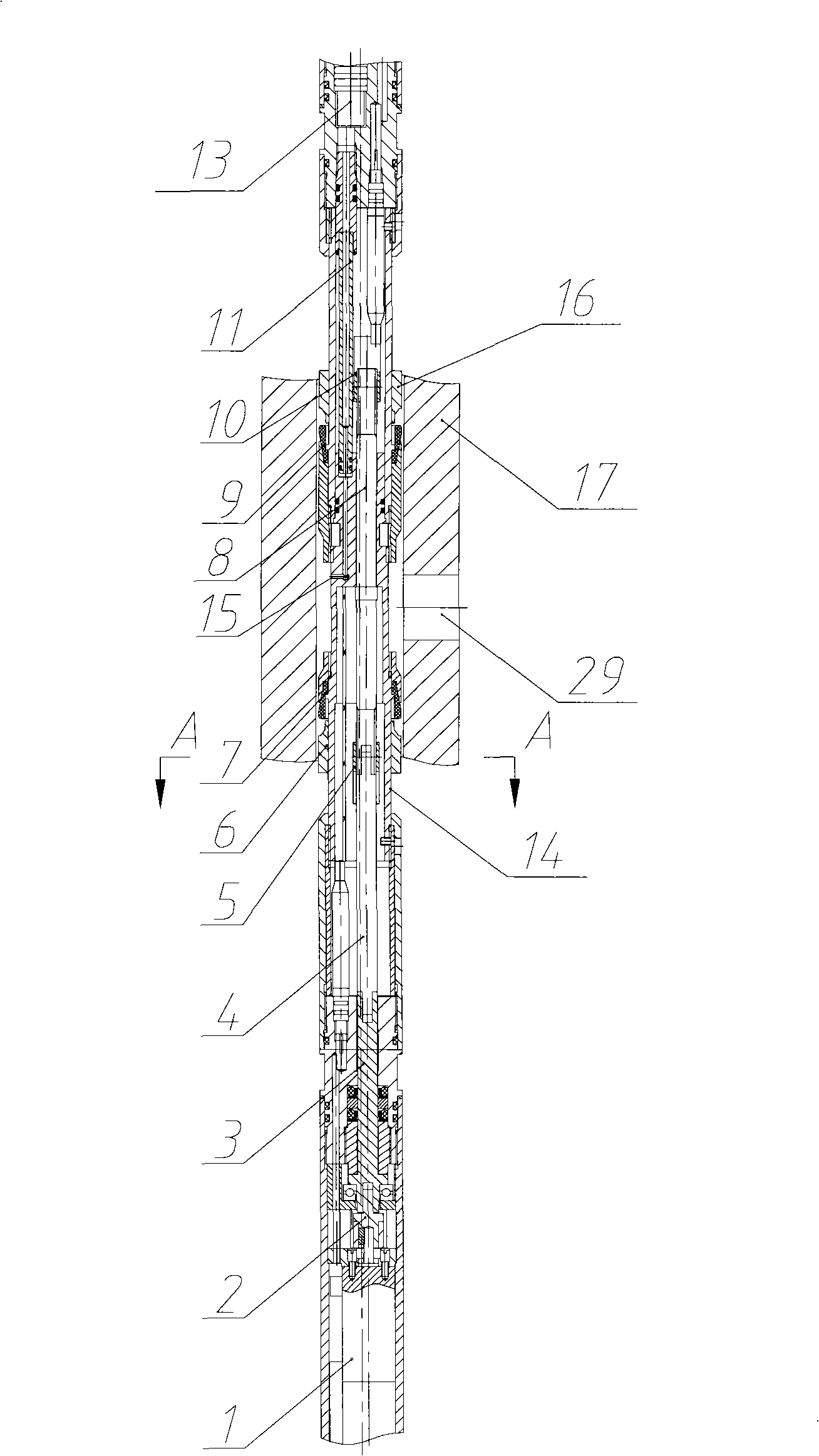

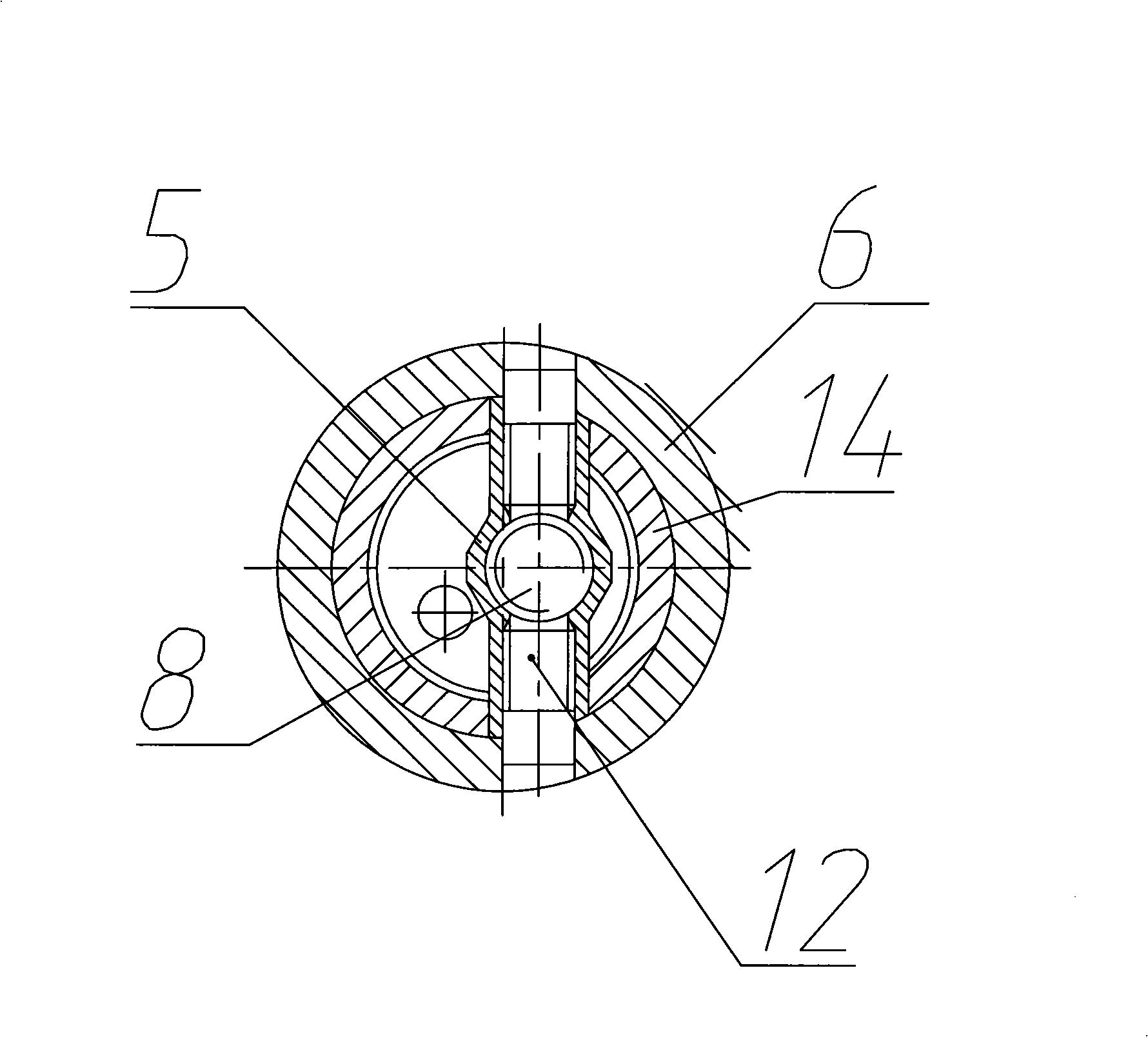

[0018] Such as figure 1 , figure 2 As shown, this embodiment of the present invention uses a piezometer as a downhole tool, wherein the formation pressure gauge 13, pressure sensing tube 11 and working cylinder 17 are introduced to facilitate the description of the working principle of the controllable section sealing device of the present invention. The controllable section sealing device of the present invention includes a cylindrical outer shell formed by the outer cylinder 14 of the pressure gauge, and also includes a motor 1, a coupling 2, an output shaft 3, a transmission shaft 4, a right-handed transmission nut 5, and a sliding sleeve 6 , 16, leather cup 7,9, transmission screw rod 8, left-handed transmission nut 10, pressure sensing tube 11 and transmission screw 12.

[0019] The lower end of the manometer outer cylinder 14 is provided with a motor 1, and the upper end is provided with a formation pressure gauge 13 and a pressure-sensing tube 11. The pressure-sensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com