Fabric graft modified full-fixation printing method

A technology of graft modification and printing method, applied in the direction of dyeing method, plant fiber, animal fiber, etc., can solve the problems of low color yield of reactive dyes, unsatisfactory color fastness requirements, heavy sewage treatment burden, etc. Achieve bright colors, reduce washing and soaping, and reduce processing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, fabric is cotton fabric

[0047] Modified formula:

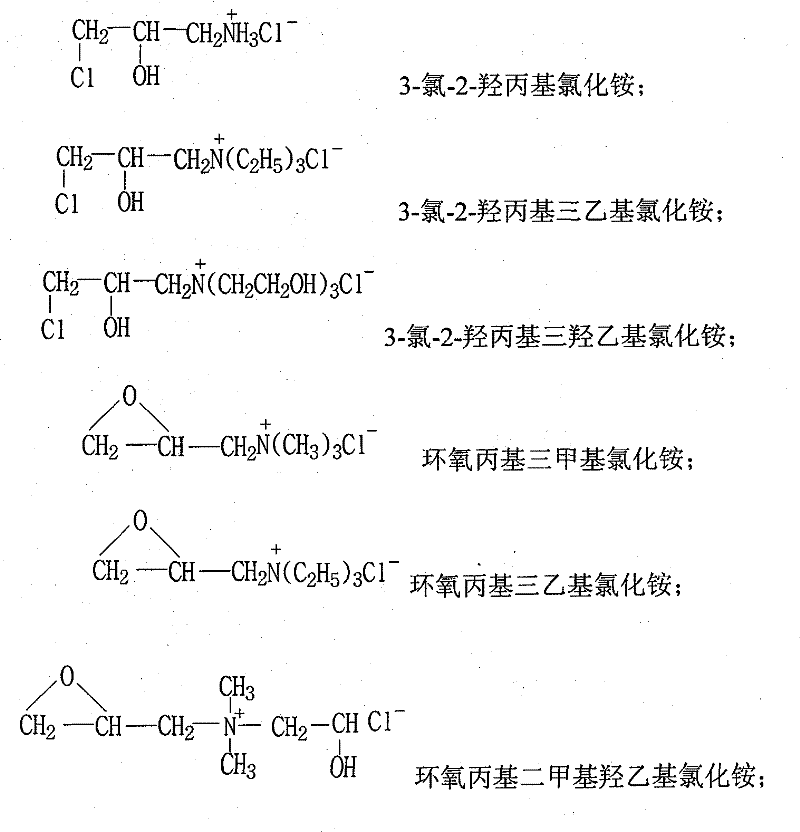

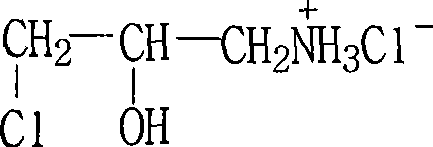

[0048] Grafting agent is 3-Chloro-2-hydroxypropylammonium chloride 0.5%

[0050] Penetrant JFC 0.01%

[0051] Modification process:

[0052] Carried out in jigger dyeing machines.

[0053] Add the above prepared solution into the dyeing machine, and put the pre-treated cotton fabric into the machine. The treatment temperature is 30°C and the time is 200 minutes. After the treatment, the fabric is fully washed to a pH value of 7 on the cloth surface.

[0054] Printing formula and process:

[0055] Sodium alginate paste (contains sodium alginate 7%) 50%

[0056] Urea 2-5%

[0057] Dye 0.5%

[0058] Sodium bicarbonate 1-2.5%

[0059] Anti-stain salt 1.5%

[0060] Appropriate amount of water

[0061] The steaming temperature is 105°C, and the time is 5 minutes.

Embodiment 2

[0062] Embodiment 2, fabric is viscose fabric

[0063] Modified formula:

[0064] Grafting agent is 3-Chloro-2-hydroxypropyltriethylammonium chloride 5%

[0065] Sodium hydroxide 4%;

[0066] The penetrating agent is Pingping plus O 1%

[0067] Modification process:

[0068] Cold pad-batch method.

[0069] Pad the viscose fabric with the treatment solution in a padding car, with a margin rate of 100%, a temperature of 25° C., and a time of 12 hours. After the treatment, wash with water until the pH value of the cloth surface is 7.

[0070] Printing formula and process:

[0071] Sodium alginate paste (contains sodium alginate 7%) 50%

[0072] Urea 5%

[0073] Dye 8%

[0074] Sodium bicarbonate 2.5%

[0075] Anti-stain salt 1.5%

[0076] Appropriate amount of water

[0077] The steaming temperature is 105°C, and the time is 5 minutes.

Embodiment 3

[0078] Embodiment 3, fabric is hemp fabric

[0079] Modified formula:

[0080] Grafting agent is 3-Chloro-2-hydroxypropyltrihydroxyethylammonium chloride 10%

[0081] Sodium Carbonate 2%.

[0082] The penetrating agent is the diffusing agent NN0 0.5%

[0083] Modification process:

[0084] Carried out in an overflow dyeing machine.

[0085] Add the above prepared solution into the dyeing machine, and put the pre-treated hemp fabric into the machine. The treatment temperature is 90°C and the time is 60 minutes. After the treatment, the fabric is fully washed to a pH value of 7 on the cloth surface.

[0086] Printing formula and process:

[0087] Puree with Guar 7-10% 50%

[0088] Urea 3%

[0089] Dye 4%

[0090] Sodium bicarbonate 1.8%

[0091] Anti-stain salt 1%

[0092] Appropriate amount of water

[0093] The steaming temperature is 100°C, and the time is 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com