Vibration reduction method for vehicular transmission shaft and vibration-damper of vehicular transmission shaft

A shock absorber and transmission shaft technology, which is applied in the field of vehicle vibration reduction, can solve the problems of small vibration reduction frequency range, etc., and achieve the effect of guaranteeing functional effects, ensuring performance stability, and facilitating product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The biggest difference from the prior art is that this specific embodiment mainly uses a liquid substance with a certain viscosity, such as lubricating oil with a certain viscosity, to absorb vibration and noise with different damping at different vibration frequencies. After a large number of tests, it has been shown that this kind of noise reduction and vibration reduction method can better absorb the vibration and noise transmitted by the vehicle drive shaft in a wide frequency range due to the application of the damping characteristics of lubricating oil during vibration to absorb vibration and noise. , which can greatly improve the ride comfort of the car.

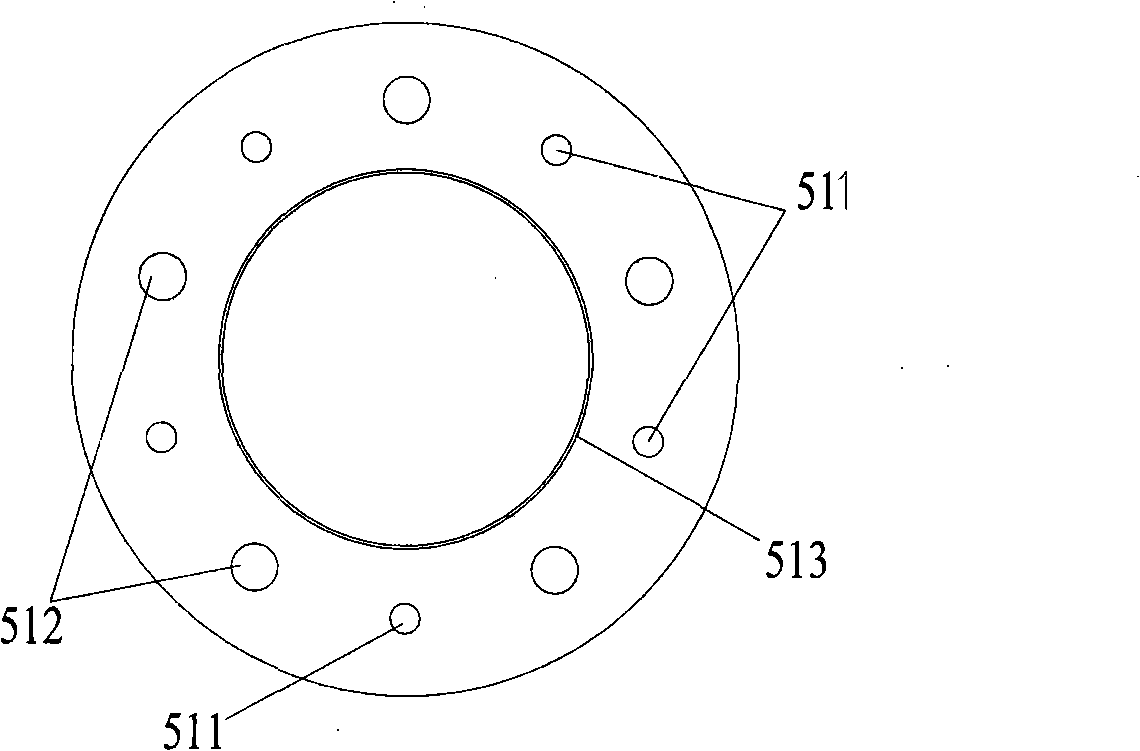

[0035] The shock absorber of the entire vehicle drive shaft is in the form of a ring. figure 1 shown, press-fit on the drive shaft tube 2. The vehicle transmission shaft shock absorber of this specific embodiment is as follows: figure 2 As shown, an inner member 51 is included, as well as a damper housing 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com