Aluminum alloy vehicle wheel and manufacturing method therefor

A technology of an aluminum alloy and a manufacturing method, which is applied in the direction of manufacturing tools, rims, vehicle parts, etc., can solve the problems of long manufacturing cycle, heavy wheel weight, inconvenient manufacturing, etc., and achieve the effect of saving materials, beautiful appearance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

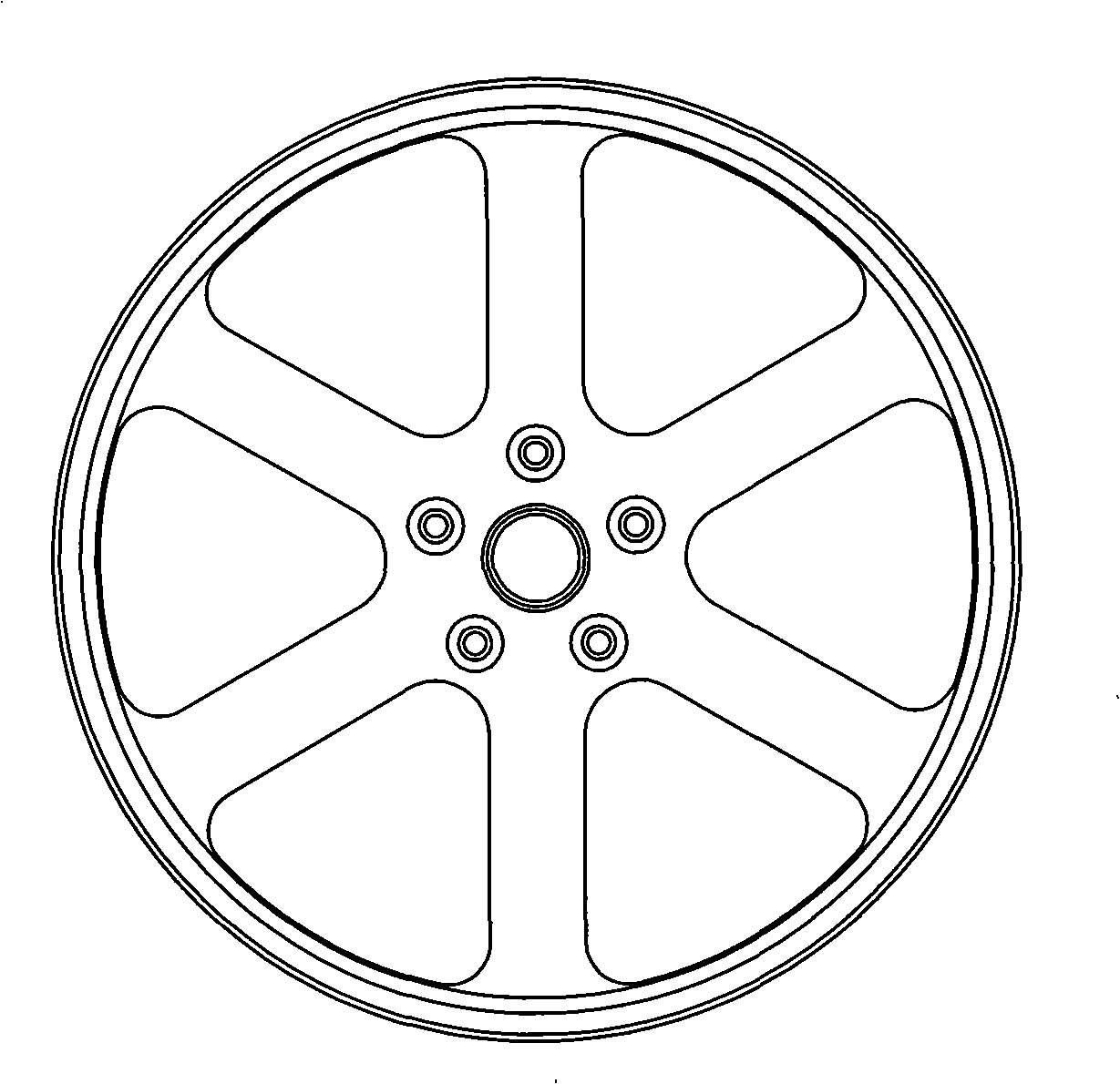

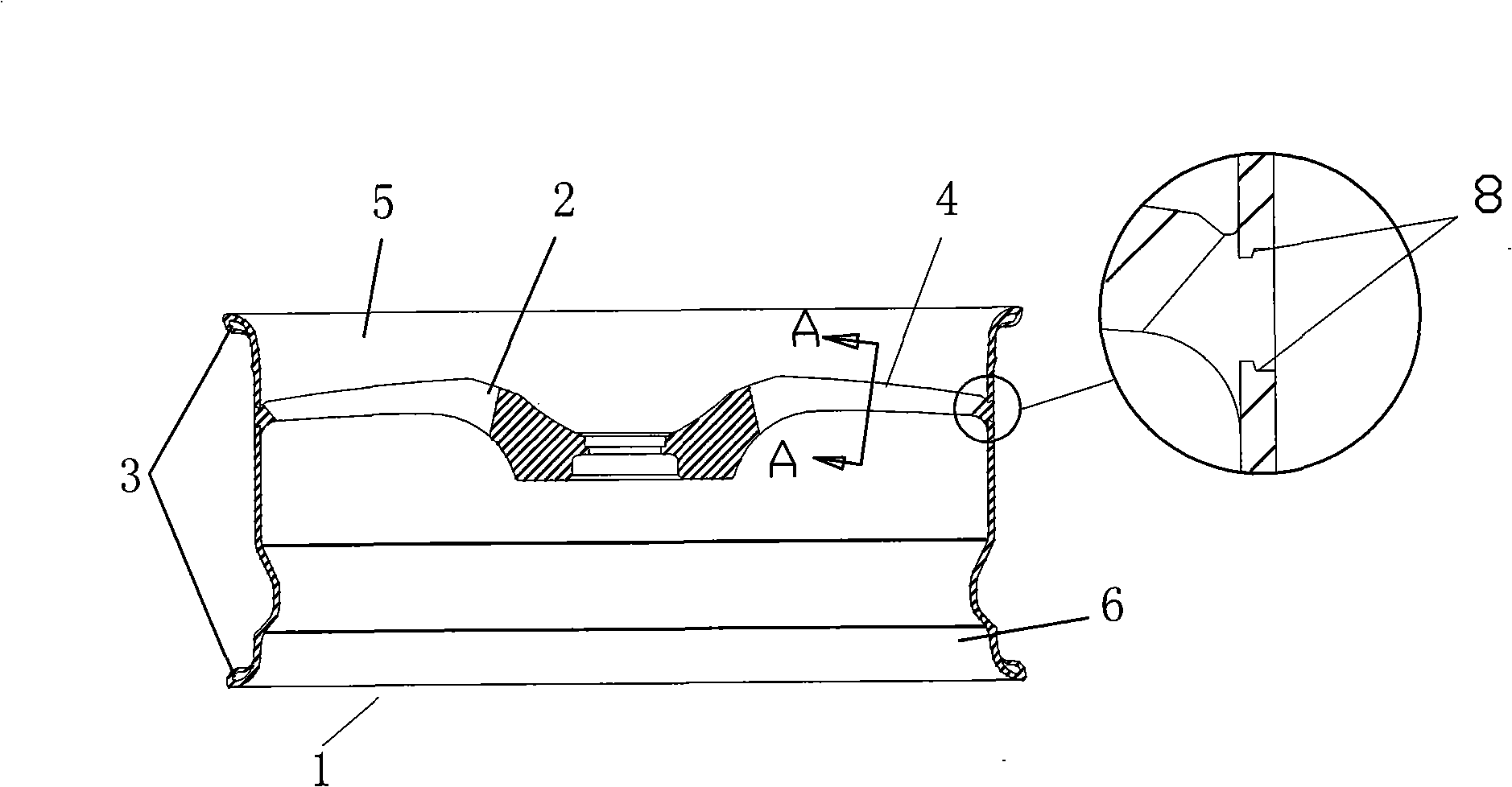

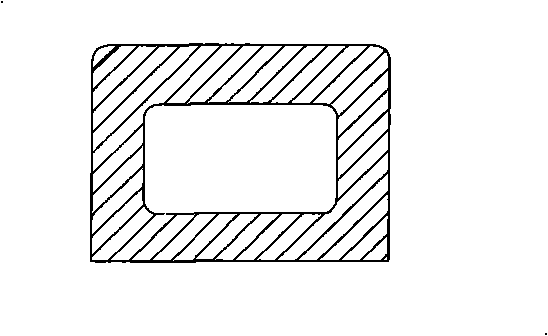

[0029] figure 1 , Figure 2a The basic structure of the first embodiment of the wheel of the present invention is shown. The aluminum alloy wheel includes an aluminum alloy rim 1 and an aluminum alloy center disc 2 arranged in the inner ring of the rim. The rim is axially butted into a whole by the outer ring 5 and the inner ring 6, the rim 3 of the rim is turned over into a hollow structure, and the spokes 4 of the center disc are arranged into a hollow structure (see Figure 2b ), the central disc 2 is connected to the butt joint of the inner and outer rings.

[0030] In this example, see Figure 2a , Image 6 , Figure 7 , the rim is formed by two axial butt joints of the outer ring 5 and the inner ring 6, and the center disc 2 is connected to the butt joint of the inner and outer rings by friction stir welding. The butt joints of the inner and outer rings and the central disk are formed into stepped joints 8 . The wall thickness of the inner and outer rings can be ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com