High pixel minitype optical auto focusing system driven by electromagnetic force

An optical automatic, high-pixel technology, applied in the direction of optics, optical components, focusing devices, etc., can solve the problems of low precision of the focusing system, limited shooting distance, and large shape, and achieve high repeatability, miniaturization of volume, and shape small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

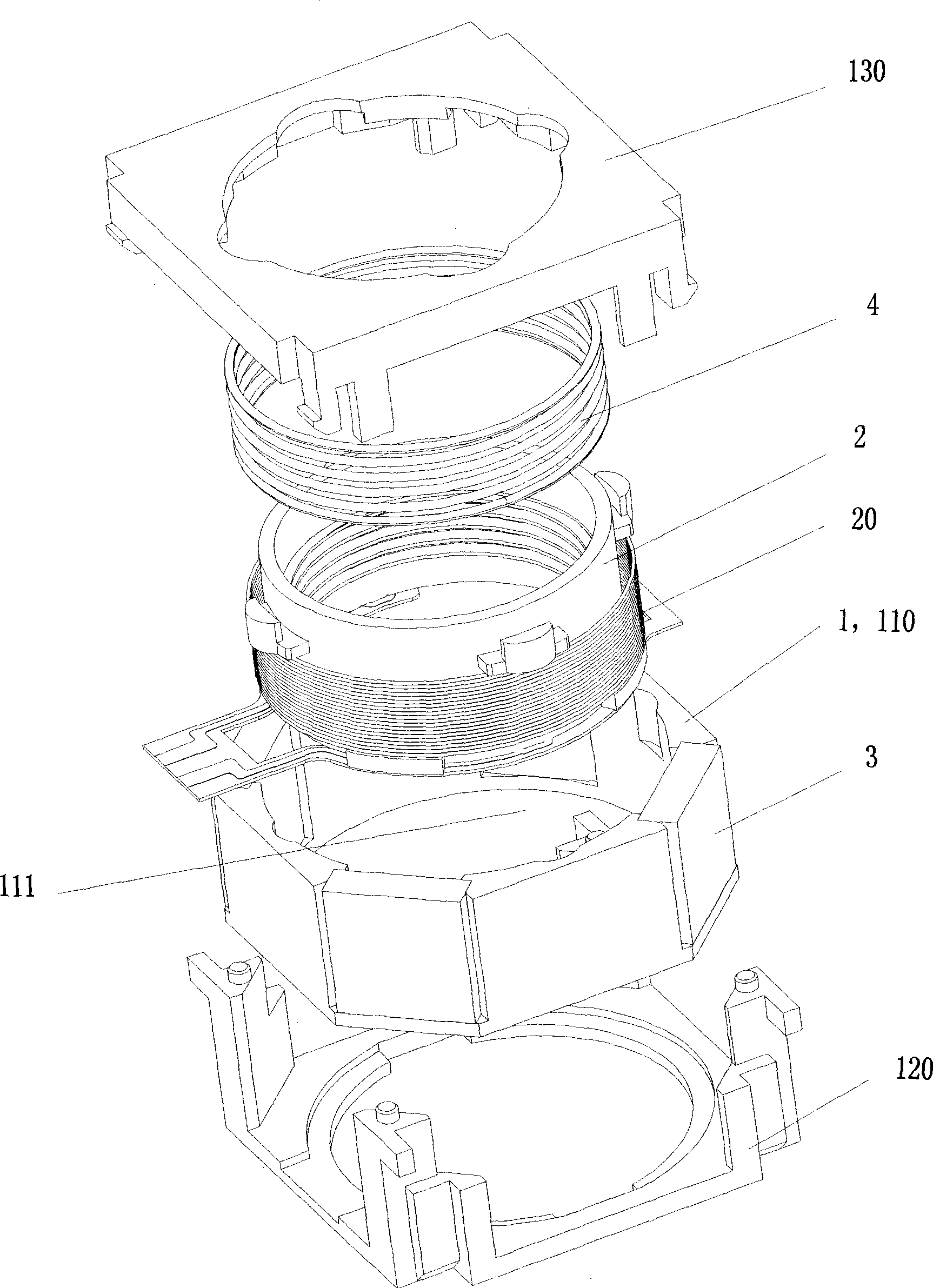

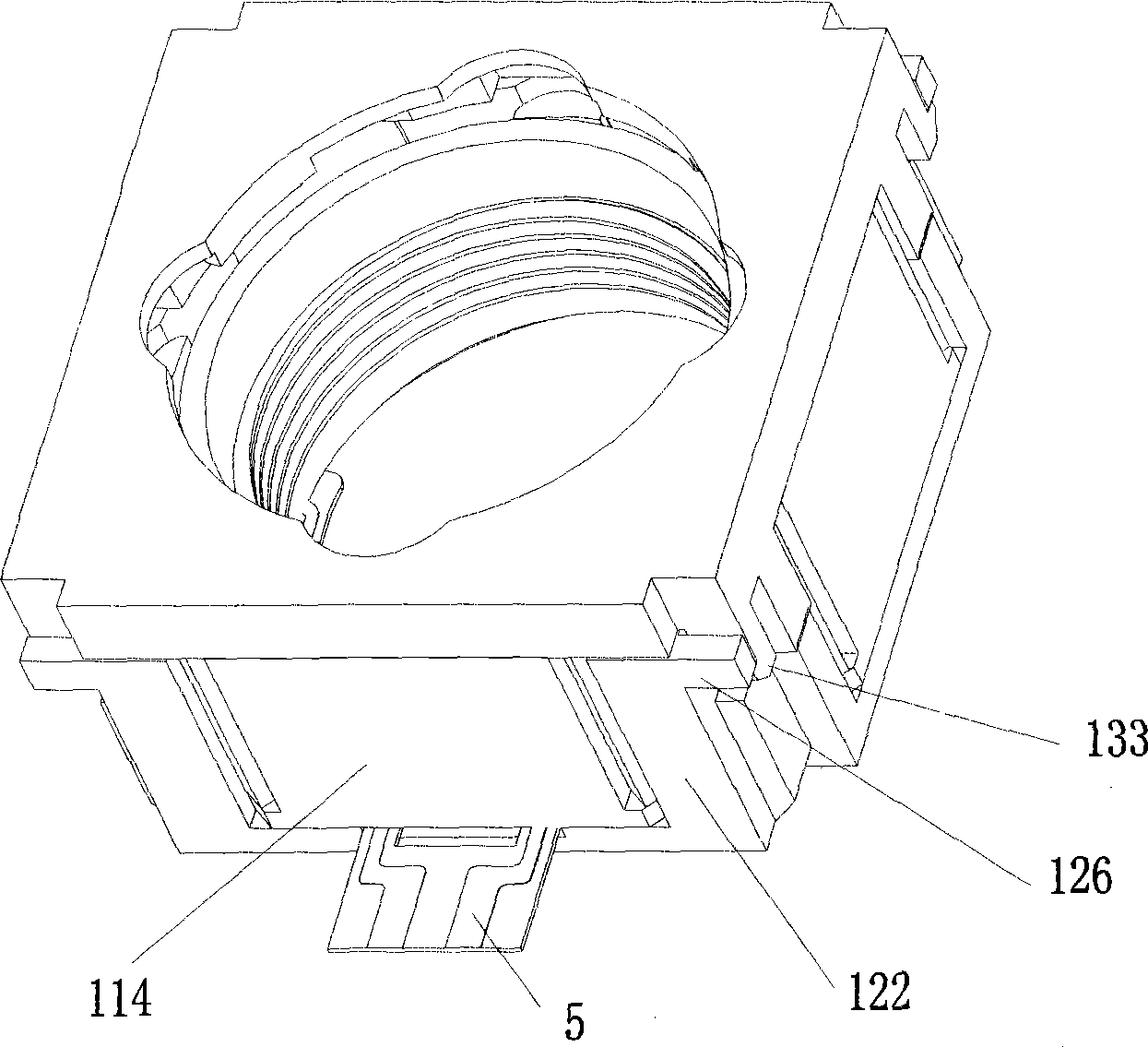

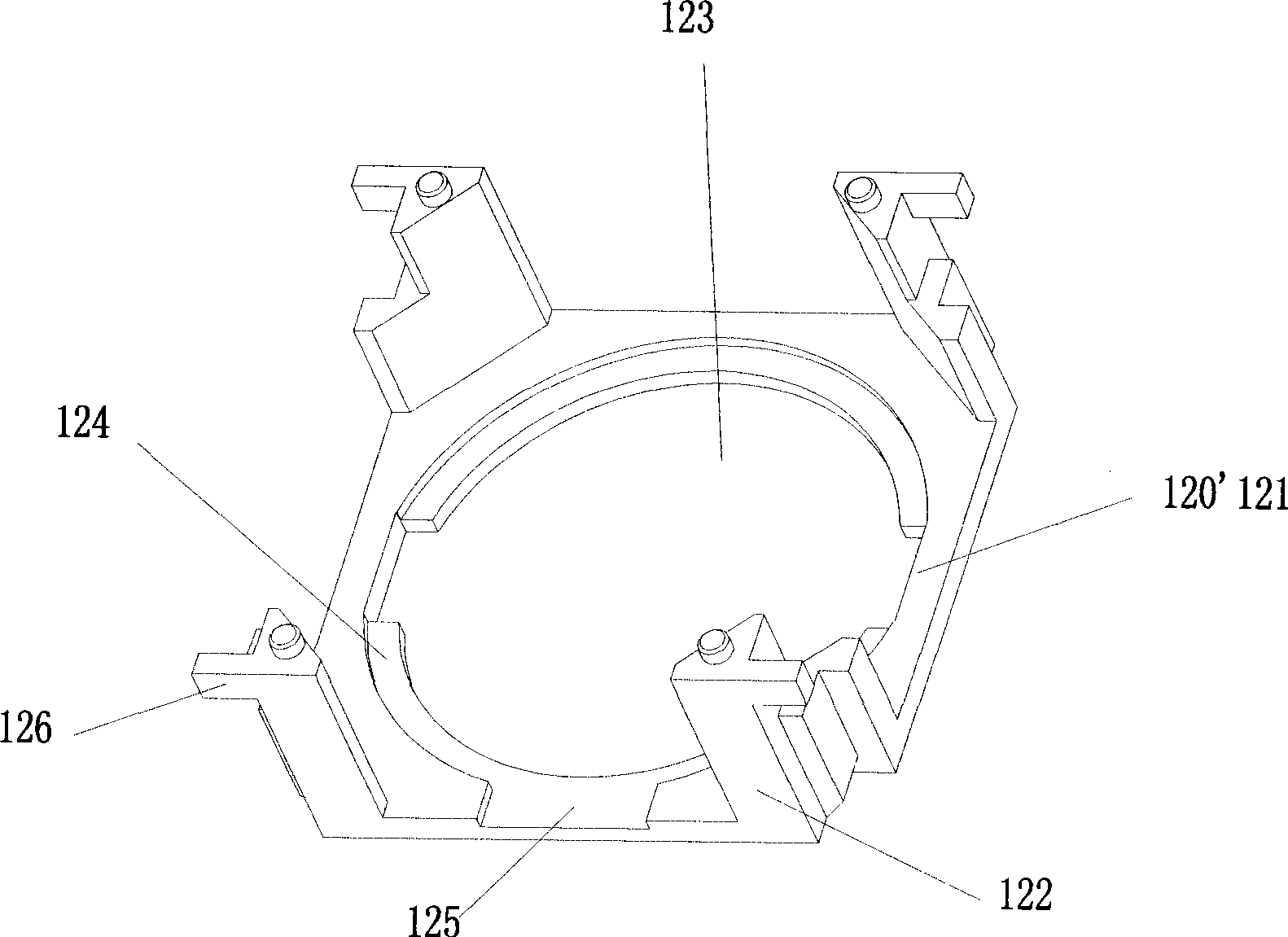

[0034] figure 1 , the optical auto-focusing system of the present invention comprises a base body 1, the base body includes a guided lens barrel 110, a lens holder 2 that can move up and down along the lens barrel is provided in the cavity 111 of the lens barrel, and there are many turns wound on the lens holder The coil 20 is equipped with a magnet 3 in the lens barrel, and a return spring 4 is arranged on the lens holder.

[0035] When focusing, we pass a current in a certain direction to the coil, and the coil is affected by the Ampere force in the magnetic field. The coil drives the lens holder to move upward in the cavity of the lens barrel, and the lens set in the lens holder moves accordingly. In order to focus; when we want to move the lens down, reduce the current until it is 0. The up and down movement of the lens is controlled by ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com