Stock-cutter

A cutting machine and frame technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of low penetration rate, complicated equipment, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

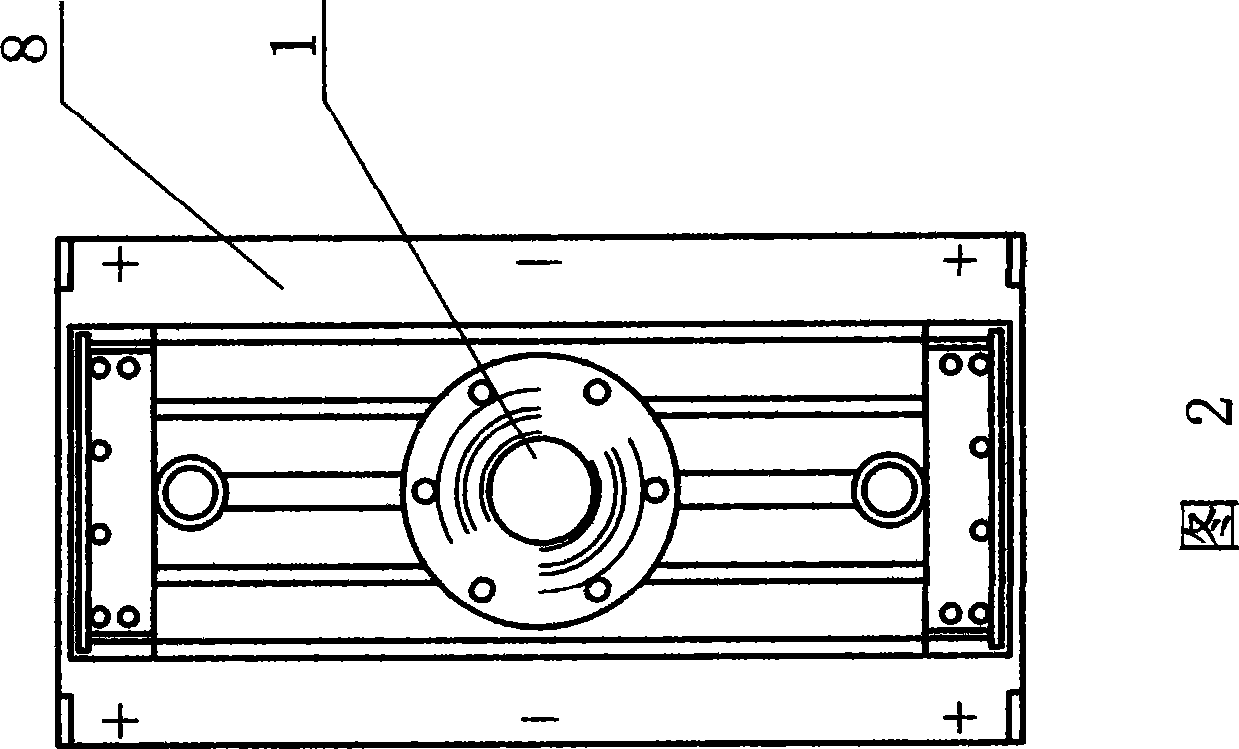

[0009] See Fig. 1, Fig. 2, the present invention comprises frame 8, and hydraulic cylinder 1 is installed on frame 8, and the piston rod of hydraulic cylinder 1 connects slide block 10, and slide block 10 is embedded in guide rail 2, and guide rail 2 is installed in frame 8 , the lower end of the slide block 10 is equipped with an upper blade 9, corresponding to the shearing direction of the upper blade 9, the frame 8 is equipped with a lower blade 7, and at the side of the upper blade 9, the slide block 10 is equipped with a spring compression structure, The spring compression structure includes a guide post 3, which is installed on the slider 10. The guide post 3 is covered with a spring 5, and the spring 5 is in a compressed state. 6. The lower end surface of the pressing block 6 is lower than the height of the upper blade 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com