Industrialization production method of pipe tobacco

A production method and technology for shredded tobacco, which are applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve problems such as high requirements for production workers' experience, difficulty in uniformity of width of shredded tobacco, poor uniformity of color, etc., and achieve excellent appearance quality, shredded tobacco, etc. The effect of uniform width and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

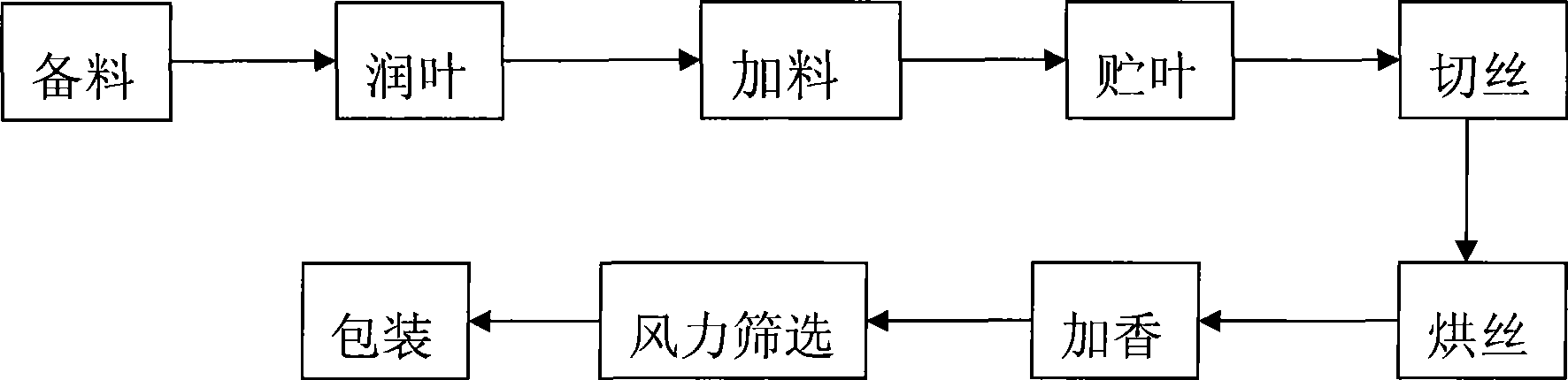

[0039] The specific implementation manners and related technical problems of the present invention will be further described in detail below in conjunction with the accompanying drawings. as attached figure 1 Shown is the production technique of the present invention, the following is an embodiment:

[0040] Material preparation process: According to the production formula list, the origin, type, variety, grade, quality and quantity of the required tobacco are organized together, and the tobacco leaves are free from mildew, odor, pollution, water and rain, etc. Same as prior art.

[0041] Leaf moistening process: Mix the prepared tobacco leaves evenly to raise the moisture and temperature to certain requirements. The water requirement for moistening leaves of the present invention is higher than that of ordinary cigarettes, and the moisture of cigarettes is generally 16°C, while the moisture of the present invention is 18±1°C. This is to facilitate the control of the moistu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com