Continuous measurement method for tobacco moisture percentage and apparatus thereof

A technology for measuring devices and moisture content, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long test period, cumbersome test methods, inability to realize online real-time monitoring of tobacco moisture content, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

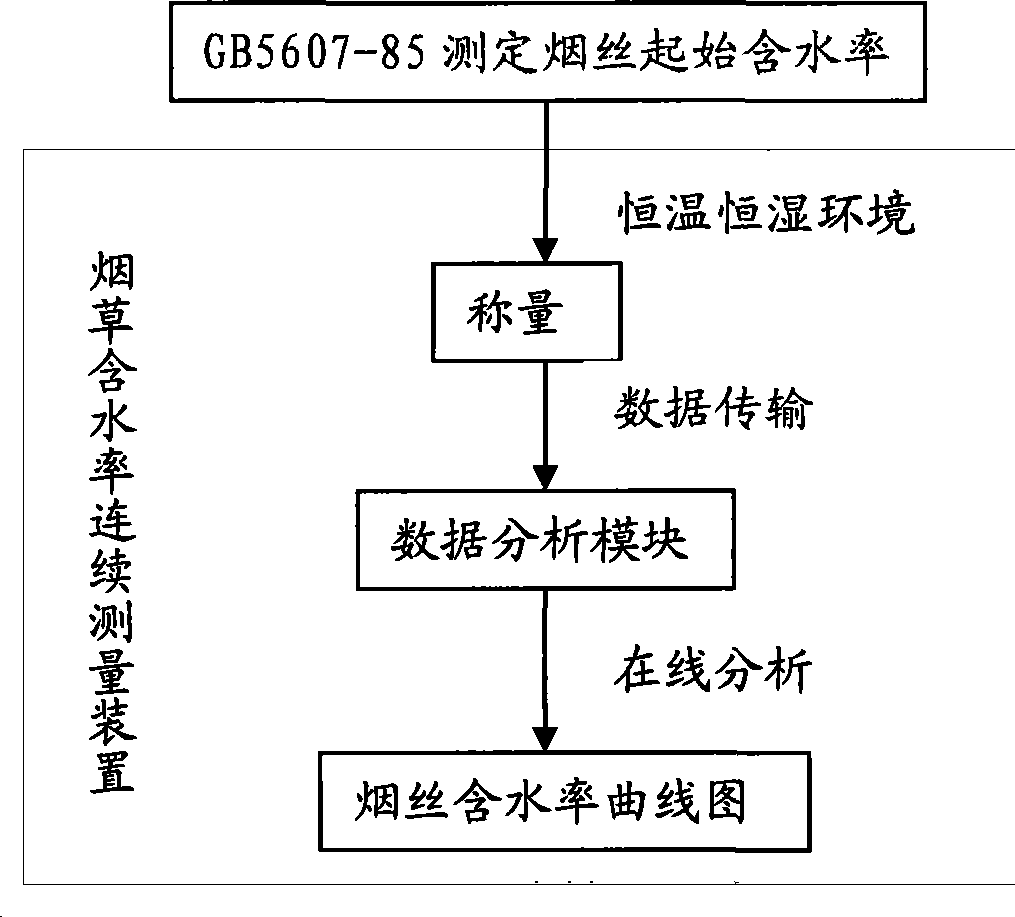

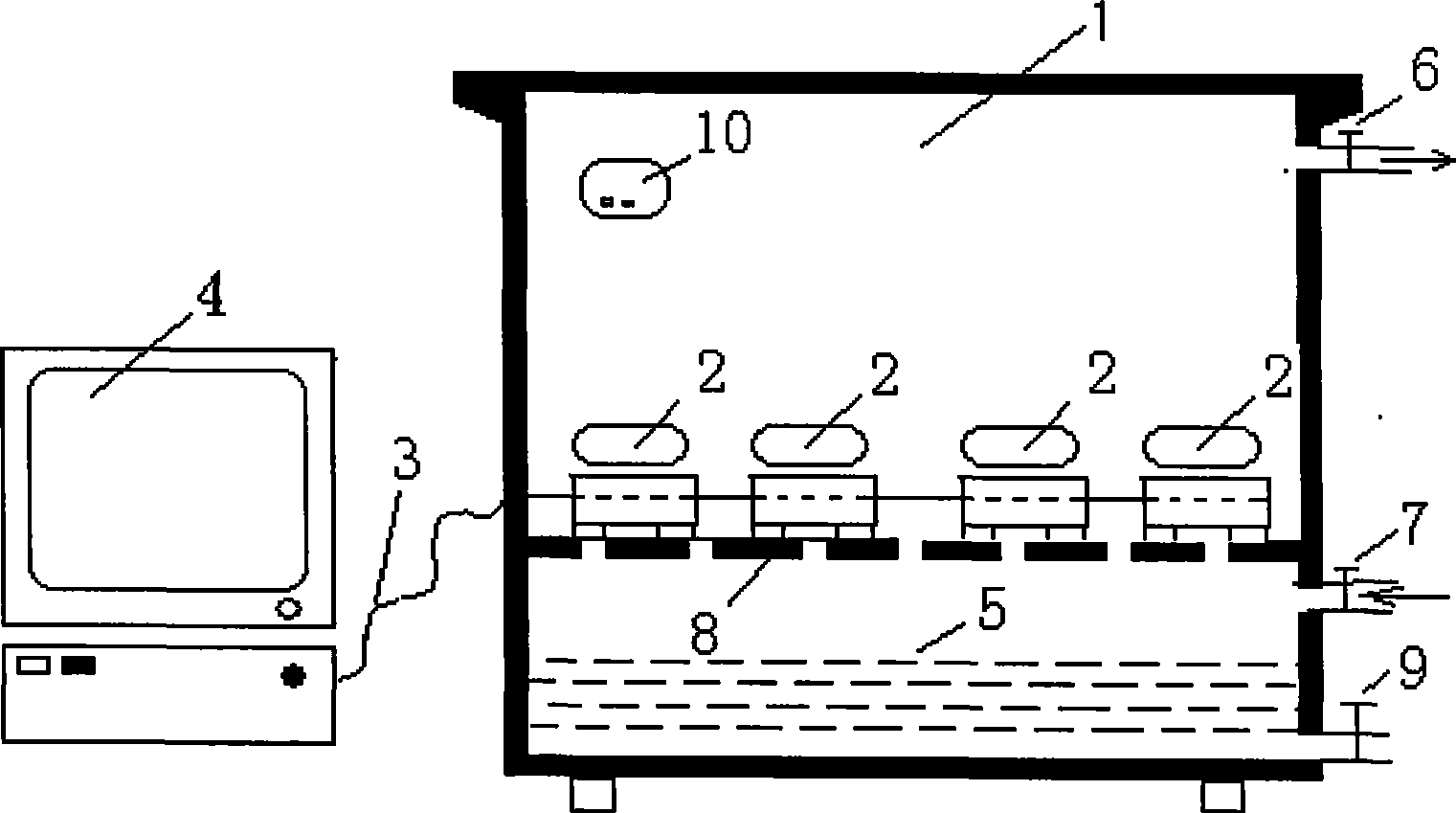

[0025] Example 1. Take 2.0000g of shredded tobacco mixed evenly, and measure its initial moisture content according to the method of national standard GB5607-85. Take another 6.0000g of shredded tobacco and place it on the weighing module. The weighing module is placed at 22℃±1℃, relatively In the constant temperature and humidity module with a humidity of 60% ± 2%, the weight is measured every 300 seconds, and the reading is transmitted to the data analysis module. When the change is less than 0.0001g, the measurement is ended. The data analysis module automatically processes the initial moisture content and the obtained data to form a series of data points of instantaneous moisture content of cut tobacco with respect to time. The curve of the instant moisture content of cut tobacco with respect to time was made, and the slight difference in moisturizing effect of tobacco moisturizing agent was compared according to the comparison of the slope of the early stage of the curve a...

example 2

[0026] Example 2. Take 4.000g of shredded tobacco mixed evenly, measure its initial moisture content according to the method of national standard GB5607-85, and take another 8.000g of shredded tobacco and place it on the weighing module. The weighing module is placed at 30℃±1℃, relatively In the constant temperature and humidity module with a humidity of 80% ± 2%, the weight is measured every 600 seconds, and the reading is transmitted to the data analysis module. When the change is less than 0.001g, the measurement is ended. The data analysis module automatically processes the initial moisture content and the obtained data to form a series of data points of instantaneous moisture content of cut tobacco with respect to time.

example 3

[0027] Example 3. Take 6.00g of shredded tobacco mixed evenly, and measure its initial moisture content according to the method of national standard GB5607-85. Take another 10.00g of shredded tobacco and place it on an electronic balance. The electronic balance is placed at 10℃±1℃, and the relative humidity is 30 In the %±2% constant temperature and humidity module, the weight is measured every 900 seconds, and the reading is transmitted to the data analysis module at the same time, and the measurement is ended when the change is less than 0.01g. The data analysis module automatically processes the initial moisture content and the obtained data to form a series of data points of instantaneous moisture content of cut tobacco with respect to time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com