Dry vacuum pump

A dry vacuum pump, vortex technology, applied in the direction of rotary piston pump, pump, rotary piston machine, etc., to achieve the effect of small vibration, easy processing and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

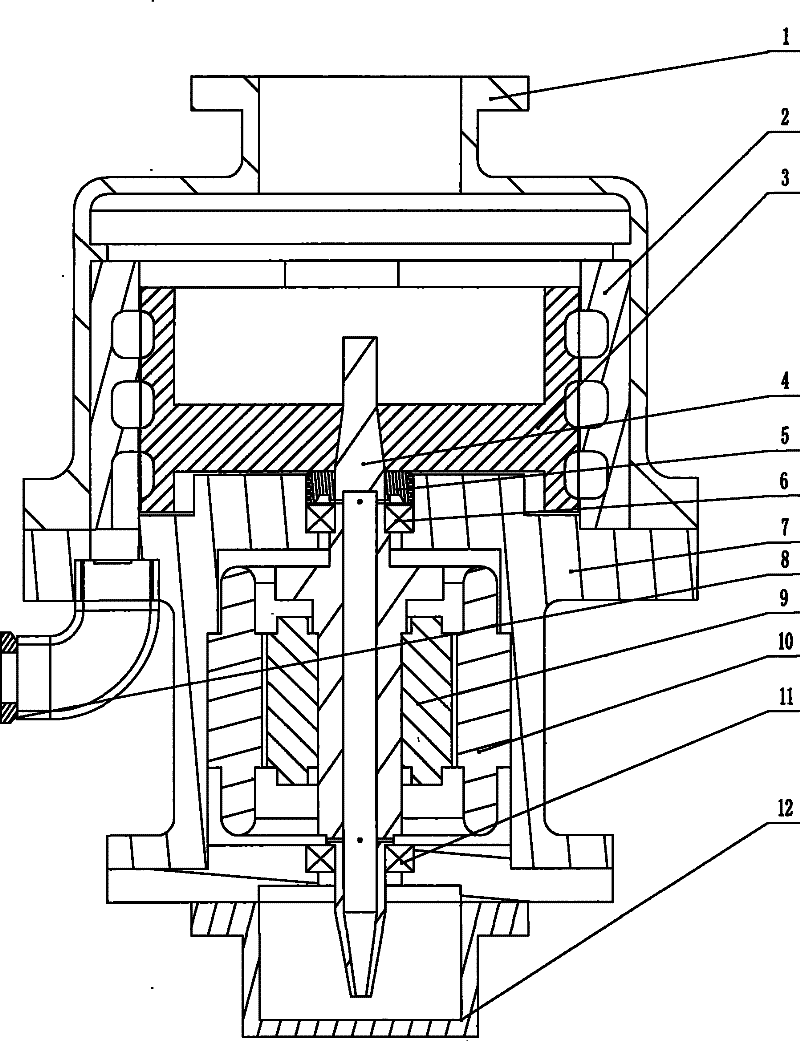

[0013] The present invention is further described in conjunction with accompanying drawing:

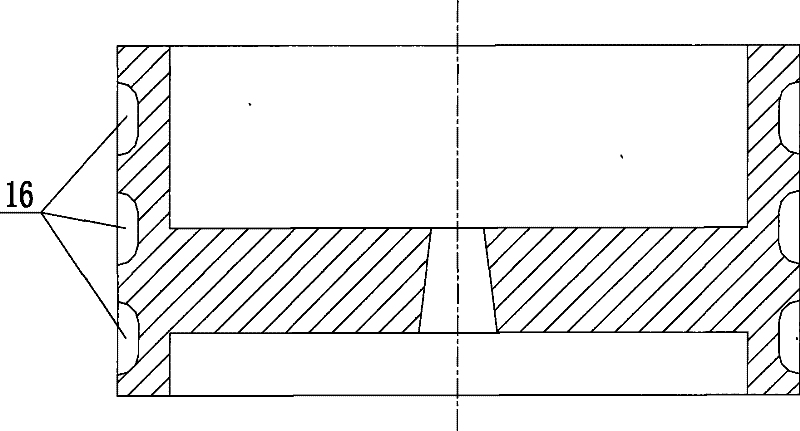

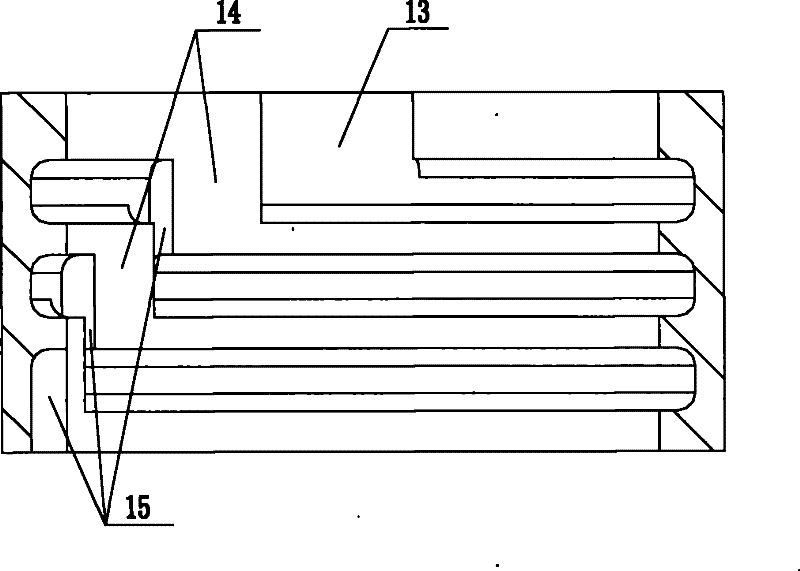

[0014] like figure 1 It is a structural schematic diagram of an embodiment of the present invention, including a base 7, a motor rotor 9 connected to the base 7, a rotor 3 connected to the main shaft 4, and an oil suction hole is provided in the center of the main shaft 4, and the oil suction hole leads into the lubricating oil pool at the bottom of the base In 12, the main shaft 4 is provided with an oil outlet, and the oil outlet is composed of a plurality of oil outlet holes, and the oil outlet holes are located near the upper bearing 6 and the lower bearing 11, providing lubricating oil for the upper bearing 6 and the lower bearing 11, and the upper bearing 6 and the lower bearing 11 adopt rolling bearings, and the seal adopts mechanical seal 5; the rotor 3 is composed of three-stage vortex-stage rotors, and the outer side of each vortex-stage rotor is provided with an annular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com