Two stage type dry coal powder entrained flow gasifier

A technology of dry coal powder and entrained flow bed, which is applied in the direction of granular/powdered fuel gasification, etc., which can solve the problem of the inability to guarantee the uniformity of the spatial uniformity of the temperature field, the reduction of the heat transfer area and quantity of the cooler, and the large temperature gradient in the furnace, etc. problems, to achieve the effect of avoiding excessive local temperature, reducing the maximum temperature and temperature gradient, and increasing the average temperature level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] see figure 1, the outer wall 11 is set as an upright cylinder, and the internal structure is composed of an upper main gasification chamber 12 and a lower chill chamber 13;

[0035] figure 1 As shown, upper nozzles 8 and lower nozzles 7 are respectively arranged at different horizontal positions in the main gasification chamber 12; on the top of the quenching chamber 13, quenching water atomizing nozzles 6 are arranged;

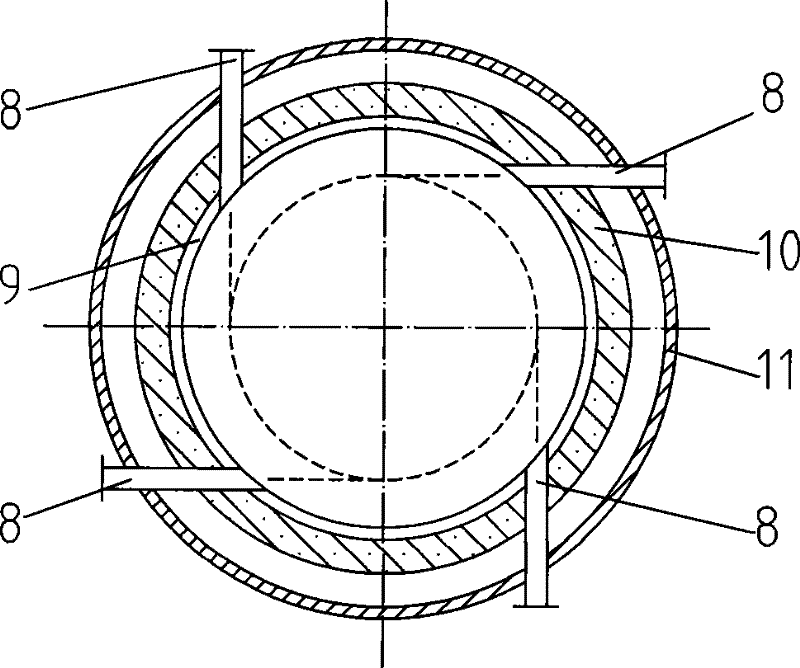

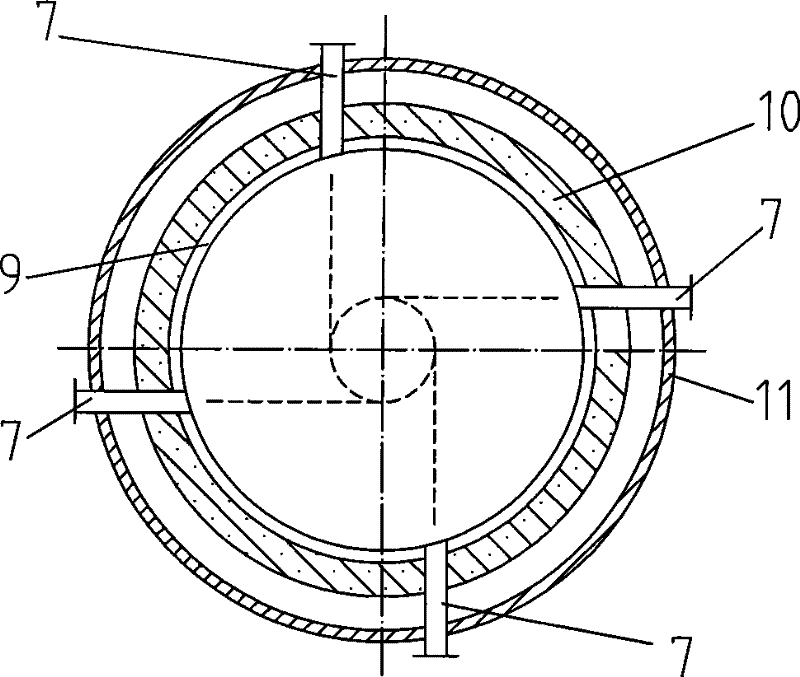

[0036] see figure 2 , image 3 and Figure 4 , the nozzles of each layer are centered on the center of the horizontal section where they are located, and at least two are evenly distributed along the circumferential tangential circle, and the rotation direction of the nozzles of each layer is the same;

[0037] like figure 1 As shown, in the present embodiment, in the quenching chamber 13, the slag outlet 1 is the bottom opening of the quenching chamber 13, the bottom of the quenching chamber 13 is the slag pool 2, and the synthesis gas outlet 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com