Method for preparing monodisperse polylactic acid microsphere

A polylactic acid microsphere, monodisperse technology, applied in the field of preparation of monodisperse polylactic acid microspheres, can solve the problem of difficult to obtain microspheres with uniform size, and achieve the effect of controllable micropipe size, smooth surface and accelerated curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

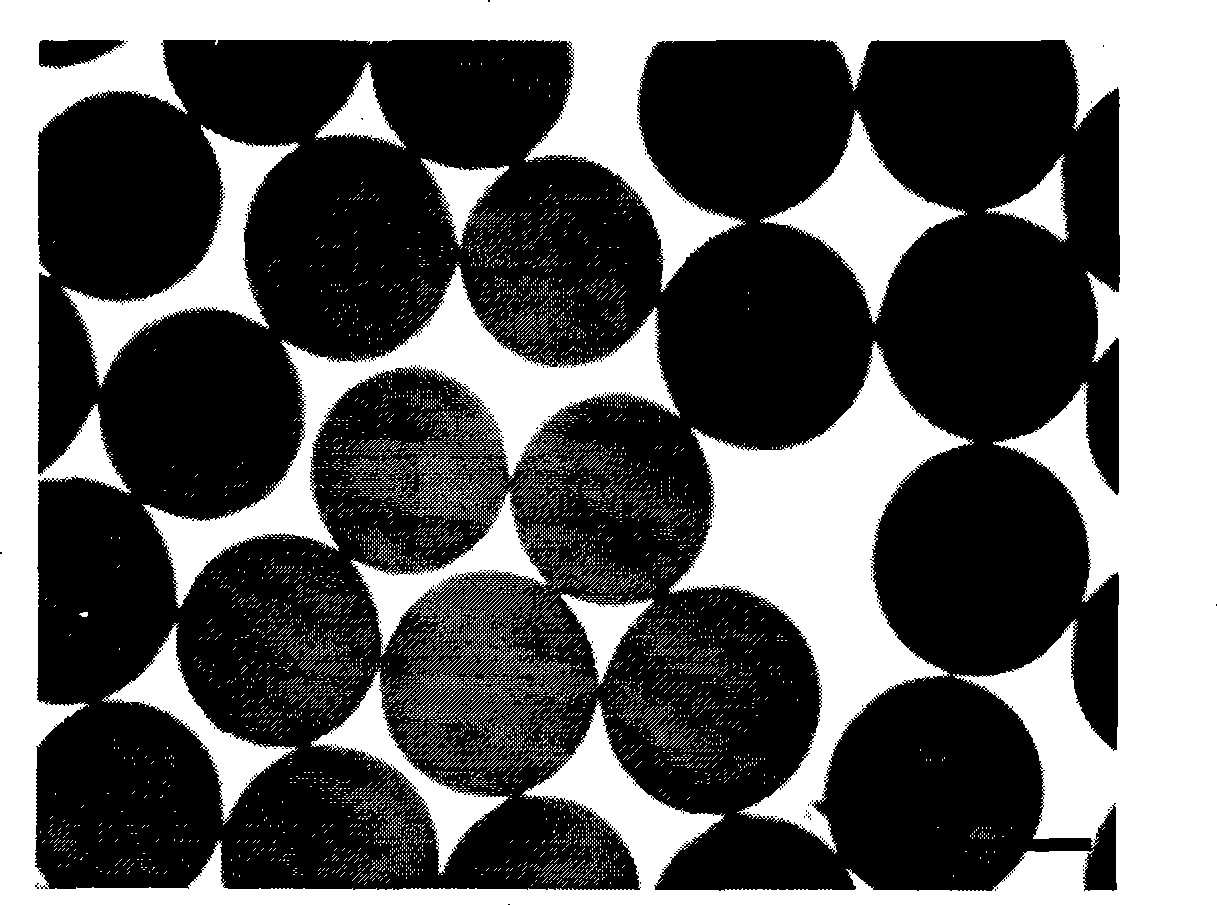

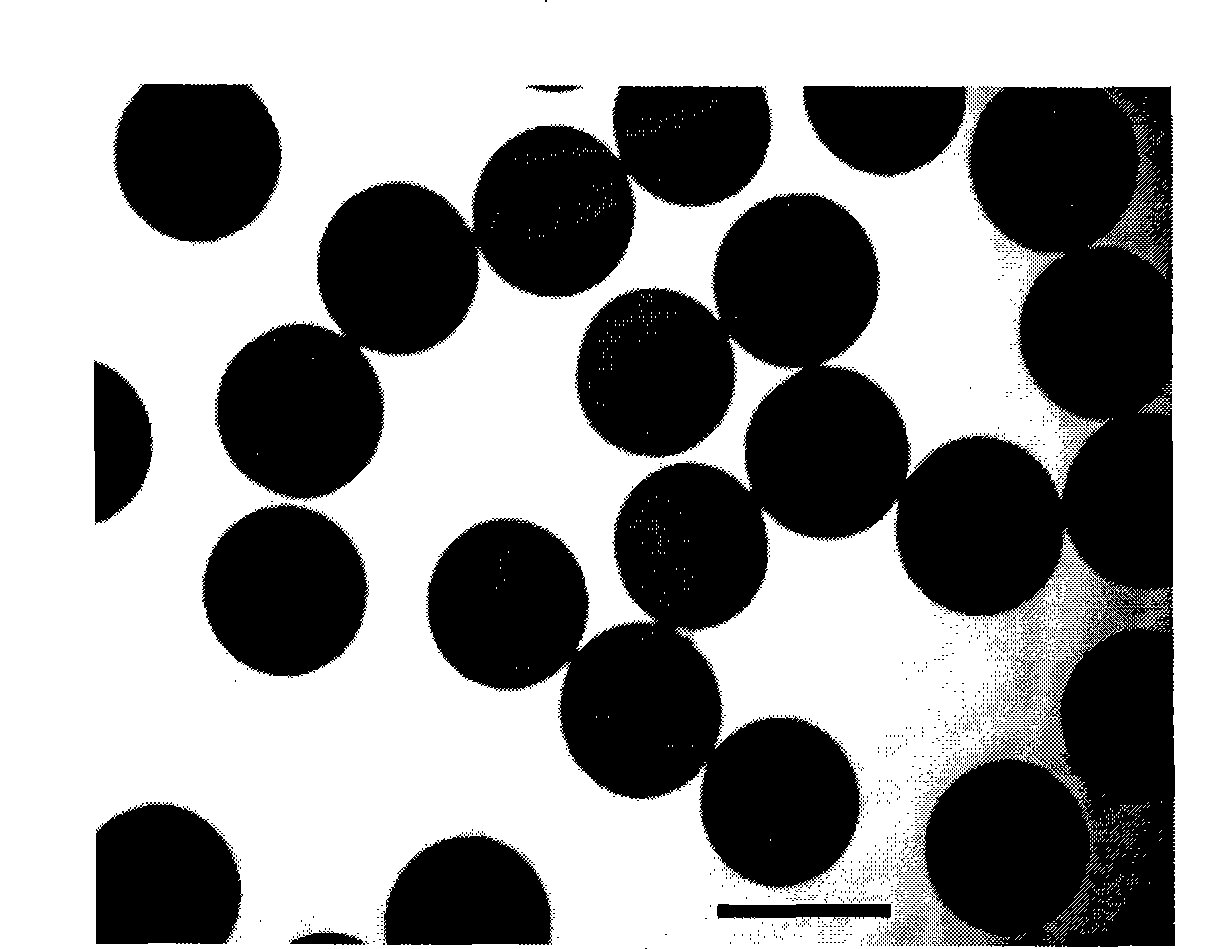

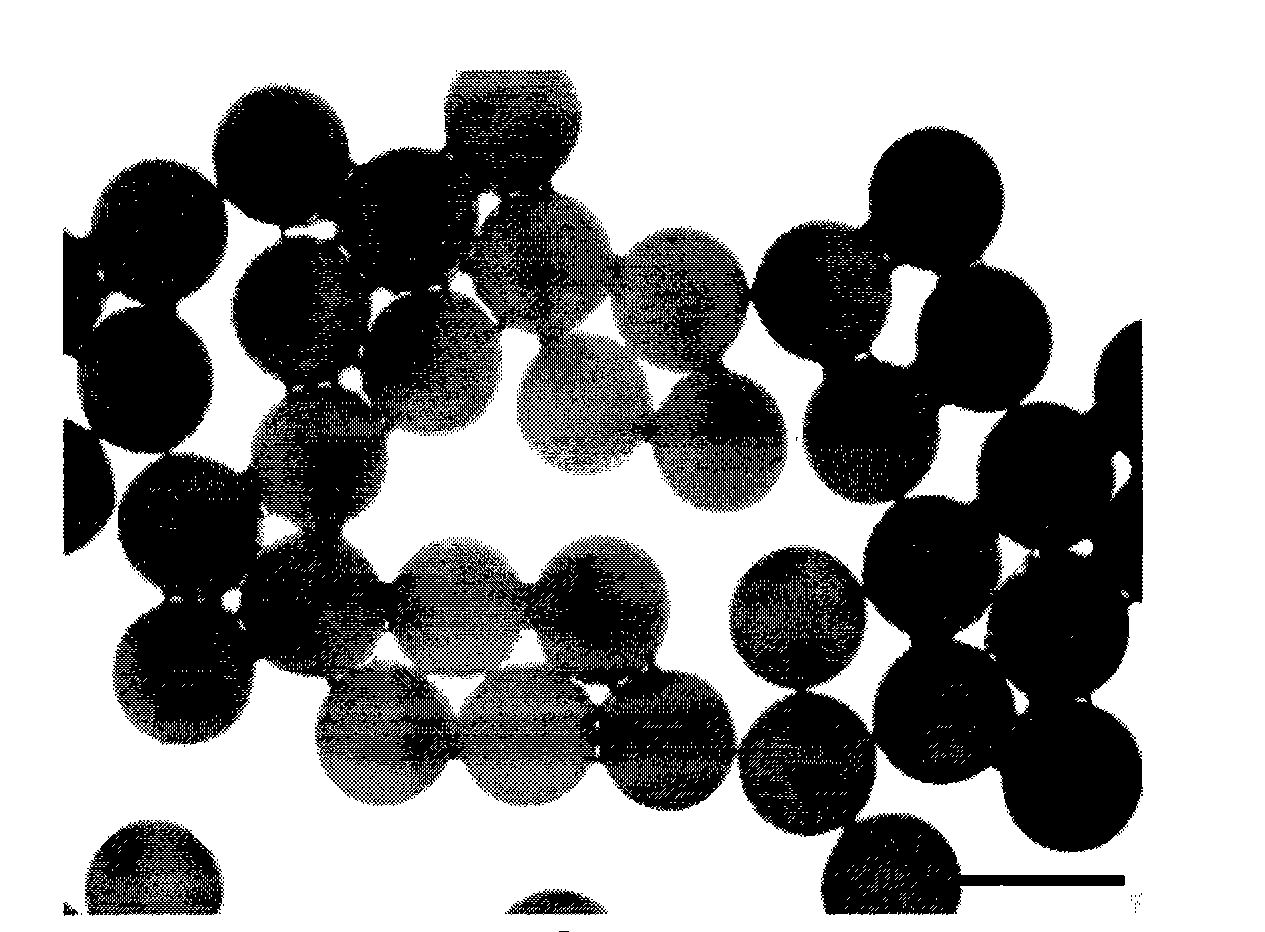

[0023] Dissolve 0.3827g of PLA with a molecular weight of 75,000 in 5mL of dichloromethane to obtain a dispersed phase solution, weigh 1.5g of polyvinyl alcohol 124 and pour it into a flask containing 100mL of water, stir with a magnet and slowly heat to 90°C to dissolve it, and obtain continuous phase solution. Put the two solutions into 10mL glass syringes respectively, place them on two propulsion pumps, and connect them to the microchannel reactor. The microtubes with relatively large inner diameters meet, and uniformly sized droplets are continuously generated where the two phases meet. Collect the generated droplets in a beaker filled with a polyvinyl alcohol solution with a concentration of 2% (g / g), then place the beaker on a frequency conversion oscillator and shake for 2 hours, until the solvent is completely volatilized, and the droplets solidify into microspheres After that, it was washed three times with deionized water and placed in an oven at 60°C for 2 hours t...

Embodiment 2

[0026] Dissolve 0.1626g of PLA with a molecular weight of 75,000 in 5mL of dichloromethane to obtain a dispersed phase solution, weigh 1.5g of polyvinyl alcohol 124 and pour it into a flask containing 100mL of water, stir with a magnet and slowly heat to 90°C to dissolve it, and obtain continuous phase solution. Put the two solutions into 10mL glass syringes respectively, place them on two propulsion pumps, and connect them to the microchannel reactor. The microtubes with relatively large inner diameters meet, and uniformly sized droplets are continuously generated where the two phases meet. Collect the generated droplets in a beaker filled with a polyvinyl alcohol solution with a concentration of 2% (g / g), then place the beaker on a frequency conversion oscillator and shake for 2 hours, until the solvent is completely volatilized, and the droplets solidify into microspheres After that, it was washed three times with deionized water and placed in an oven at 50°C for 2 hours t...

Embodiment 3

[0029] Dissolve 0.4g of PLA with a molecular weight of 55,000 in 10mL of dichloromethane to obtain a dispersed phase solution, weigh 3g of polyvinyl alcohol 124 and pour it into a flask containing 100mL of water, stir it with a magnet and slowly heat it to 90°C to dissolve it, and obtain a continuous phase solution. Put the two solutions into 10mL glass syringes respectively, place them on two propulsion pumps, and connect them to the microchannel reactor. The thicker microtubules meet and continuously generate uniformly sized droplets where the two phases meet. Collect the generated droplets in a beaker filled with a polyvinyl alcohol solution with a concentration of 1.5% (g / g), then place the beaker on a variable frequency oscillator and shake for 3 hours, until the solvent is completely volatilized, and the droplets solidify into microspheres Finally, it was washed with deionized water for 4 times and placed in an oven at 80°C for 1 hour to obtain monodisperse PLA microsph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com