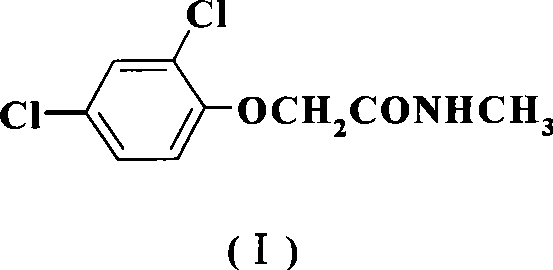

Method for preparing N-methyl-2-(2,4-dichlorophenoxy) acetamide

A technology of dichlorophenoxy and chlorophenoxy, applied in the preparation of N-methyl-2-acetamide, in the field of phenoxyamide compounds, can solve the problems of low cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 10g (0.05mol) of N-methyl-2-(4-chlorophenoxy)acetamide into a 250mL four-necked flask equipped with a stirrer, thermometer, condenser and dropping funnel, add 60mL of formic acid, and heat to 40°C. A mixture of 9.5g (0.07mol) of sulfuryl chloride and 20mL of formic acid was added dropwise with stirring, and then kept at 40°C for 5h. After the reaction was completed and part of the solvent was removed, the residue was poured into 300 mL of water for water analysis, and after suction filtration, washing and recrystallization, a white solid N-methyl-2-(2,4-dichlorophenoxy)ethane was obtained. Amide 10g, its yield is more than 85%, melting point: 106.5°C-106.8°C. IR(KBr), v / cm -1 : 3317(N-H), 1664(C=O), 1249cm -1 (-O-), 1 HNMR (CDCl 3 ): 7.40 (m, 1H, -C 6 h 5 ), 7.20 (m, 2H, -C 6 h 5 ), 6.60 (q, 1H, -NH-), 4.45 (2H, -CH 2 -), 2.80 (d, 3H, -CH 3 ). Elemental Analysis C 9 h 9 NO 2 Cl 2 , measured value (calculated value) / %: W(C)=46.12(46.18), W(H)=3.84(3.8...

Embodiment 2

[0020] Add 10g (0.05mol) of N-methyl-2-(4-chlorophenoxy)acetamide into a 250mL four-necked flask equipped with a stirrer, thermometer, condenser and dropping funnel, add 60mL of formic acid, and heat to 60°C. A mixture of 9.5g (0.07mol) of sulfuryl chloride and 20mL of formic acid was added dropwise with stirring, and then kept at 60°C for 5h. After the reaction was completed and part of the solvent was removed, the residue was poured into 300 mL of water for water analysis, and after suction filtration, washing and recrystallization, a white solid N-methyl-2-(2,4-dichlorophenoxy)ethane was obtained. Amide 6.5g, the yield is 56%.

Embodiment 3

[0022] Add 10g (0.05mol) of N-methyl-2-(4-chlorophenoxy)acetamide into a 250mL four-necked flask equipped with a stirrer, thermometer, condenser and dropping funnel, add 60mL of formic acid, and heat to 30°C. A mixture of 8.2 g (0.06 mol) of sulfuryl chloride and 20 mL of formic acid was added dropwise with stirring, and then kept at 30° C. for 5 h. After the reaction was completed and part of the solvent was removed, the residue was poured into 300 mL of water for water analysis, and after suction filtration, washing and recrystallization, a white solid N-methyl-2-(2,4-dichlorophenoxy)ethane was obtained. The amide was 5.8 g, and the yield was 49.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com