Hydroxylethylidene diphosphonic acid with arsenic content <=3ppm and preparation technique thereof

A technology for hydroxyethylene diphosphonic acid and content, which is applied in the field of hydroxyethylene diphosphonic acid and its preparation technology, can solve problems such as environmental pollution, restricted use fields, etc., so as to reduce environmental pollution and treat calcium metabolism disorders. , the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

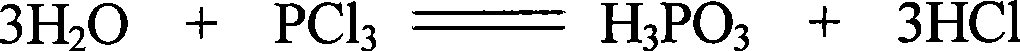

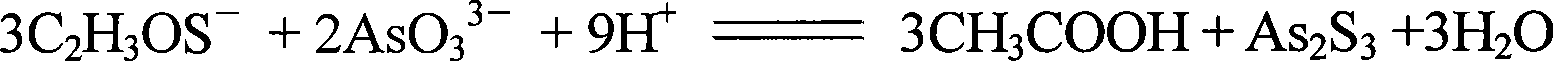

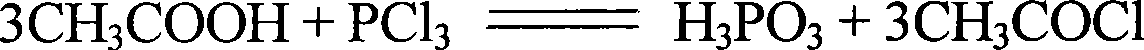

Method used

Image

Examples

Embodiment 1

[0034] The quality index of the produced hydroxyethylene diphosphonic acid of the present invention is:

[0035] Active ingredient, % 58.0-62.0

[0036] Phosphorous acid (as PO 3 3- ) content, % ≤ 2.0

[0037] Phosphoric acid (as PO 4 3- ) content, % ≤0.5

[0038] Chloride (as Cl - meter) content, % ≤0.5

[0039] Calcium Chelation Value, mgCaCO 3 / g ≥500

[0040] Iron (as Fe 2+ meter) content, ppm ≤15

[0041] PH(1% aqueous solution, 20℃) ≤2.0

[0042] Density (20℃), g / cm 3 ≥1.44

[0043] Arsenic content, ppm ≤1.0.

[0044] Production technology of the present invention is:

[0045] The first step, put 6000kg of acetic acid and 10-15kg of ammonium thioacetate into the reaction kettle, under the condition of stirring, control the temperature at 50-60°C and control the pressure below 200mmHg, slowly add 2500kg of phosphorus trichloride dropwise, after the dropwise addition, put 10-60 Put 15kg of ammonium thioacetate into the reaction kettle, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com