Numerical control polishing mechanical hand of optical elements of large caliber

An optical element and manipulator technology, applied in optical elements, optics, lenses, etc., can solve the problems of long processing cycle, no large-diameter optical element CNC polishing manipulator, and large workload, etc., to improve processing efficiency and processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

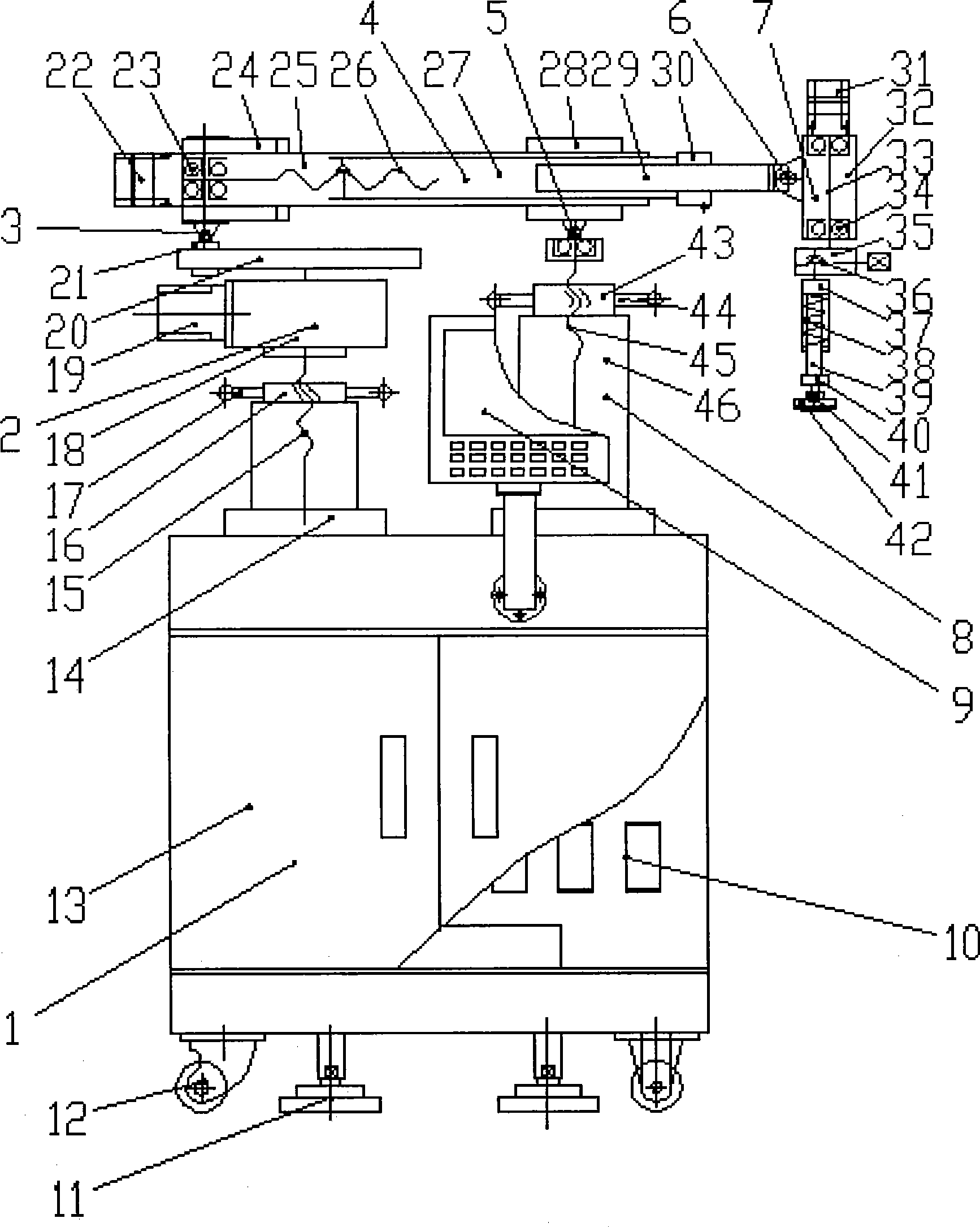

[0017] The invention according to figure 1 The structure shown is implemented as follows:

[0018] Screw jack 11 made of bicycle, chassis diameter Φ100mm, ejector rod diameter Φ25mm, material is 45# steel, connected with base box 13 by thread, row wheel 12 is purchased, and adopts PU heavy-duty brake wheel from Dongguan Jincheng Polyurethane Caster Products Co., Ltd. , Base box 13 adopts 20mm thick Q235 steel plate welding system.

[0019] The wobble plate support 14 is a hollow cavity, made of cast iron; the wobble plate lifting nut 16 and the wobble plate lifting screw 15 in the lifting and lowering numerical control wobble plate system 2 have a pitch of 7mm, and the material is 45# steel; the worm gear reducer 18 Shanghai Nengwei Reducer Co., Ltd. RV turbine worm reducer is used, the reduction ratio is 1:50; the swing plate motor 19 adopts Sanyo AC servo motor; the swing plate 20 and the eccentric shaft 21 are made of 45# steel, and the eccentric shaft 21 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com