Disinfectant ointment

An ointment, sterilization and disinfection technology, applied in the directions of ointment delivery, application, biocide, etc., can solve the problems of alcohol skin irritation, continuous effect can not provide sufficient effect, skin damage, etc., to inhibit irritation, prevent infectious diseases, prevent Effects of skin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

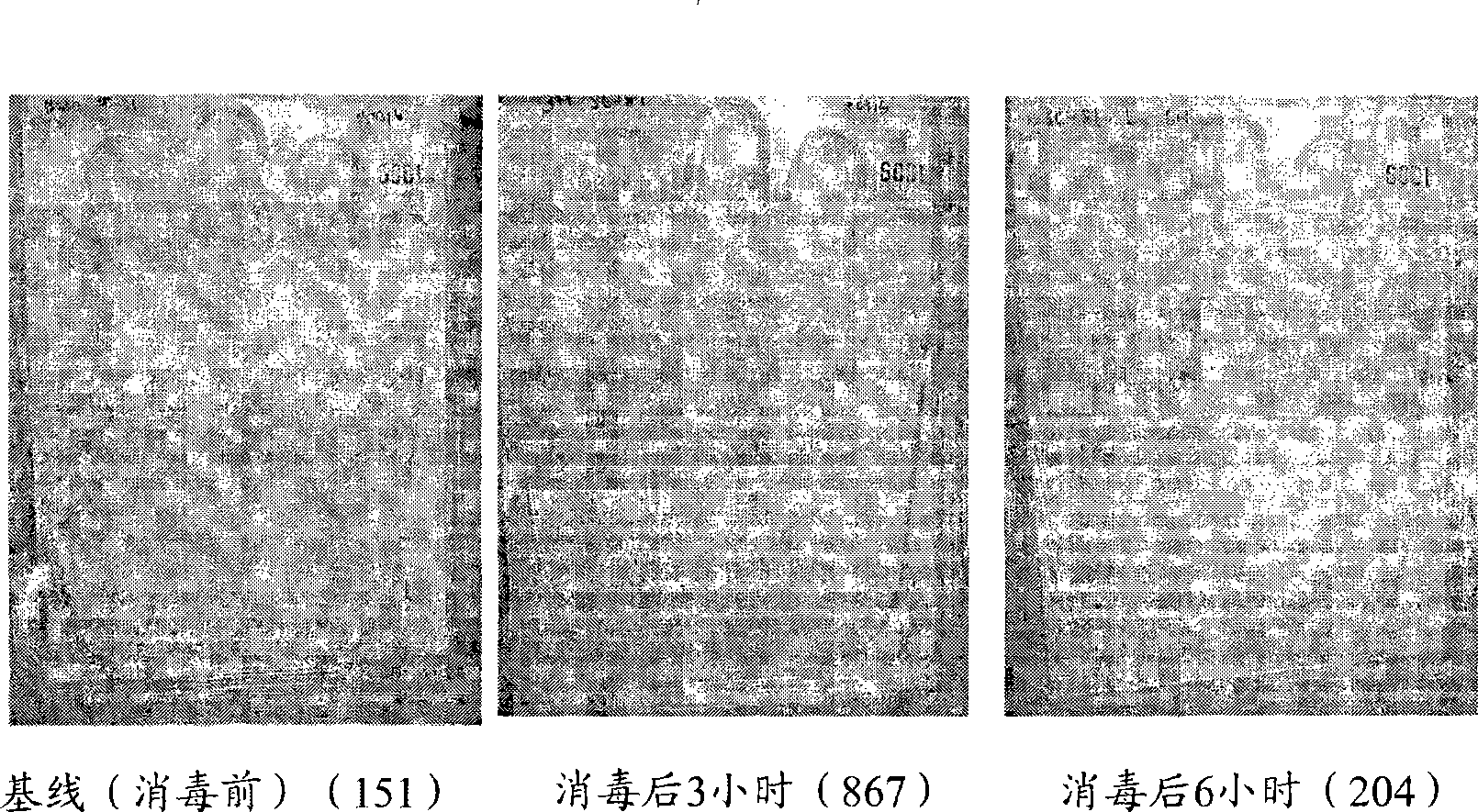

Image

Examples

Embodiment 1~3、 comparative example 1 and 2

[0106] In Table 1, the oil phase components were heated to 75-80°C and stirred to dissolve, and then the temperature was adjusted to 60±2°C. The water phase components are heated to 65-70°C to completely dissolve the surfactant, and then the temperature is adjusted to 60±2°C. Next, while stirring with a homomixer, the oil phase was slowly added to the water phase. Afterwards, further stirred with the rotating speed of 8000rpm for 2 minutes, cooled to room temperature while stirring, finally obtained the ointment (preparation 1) of embodiment 1 in table 1, the ointment (preparation 2) of embodiment 2, the ointment of embodiment 3 Ointment (formulation 3), ointment of Comparative Example 1 (comparative formulation 1), and ointment of Comparative Example 2 (comparative formulation 2).

[0107] [Table 1]

[0108]

Embodiment 4

[0110] (1) Cetyl alcohol 4.0% by mass

[0111](2) Stearic acid 1.5% by mass

[0112] (3) Palm oil triglyceride 1.0% by mass

[0113] (4) Glyceryl triethylhexanoate 2.0% by mass

[0114] (5) Silicone oil 2.5% by mass

[0115] (6) Squalane 4.0% by mass

[0116] (7) POE (30) cholesteryl ether 4.0% by mass

[0117] (8) Glyceryl monostearate 1.0% by mass

[0118] (9) Ethanol 9.0% by mass

[0119] (10) Propylene glycol 18.0% by mass

[0120] (11) Glycerin 12.0% by mass

[0121] (12) Sodium pyrrolidone carboxylate 2.0% by mass

[0122] (13) Chlorhexidine gluconate 0.5% by mass

[0123] (14) Betaine 3.0% by mass

[0124] (15) pure water sufficient

[0125] Total 100.0% by mass

[0126] The above-mentioned components (1) to (10) are heated to 75 to 80° C. to dissolve, and then the temperature is adjusted to 70±2° C. to prepare an oil phase. On the other hand, the above-mentioned components (11) to (15) are heated to 70 to 75°C, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com