Torque sensor and measuring system

A torque sensor and stress sensor technology, applied in the field of sensors, can solve the problems of multi-material, inability to realize real-time detection of mechanical equipment, long time required for installation and debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

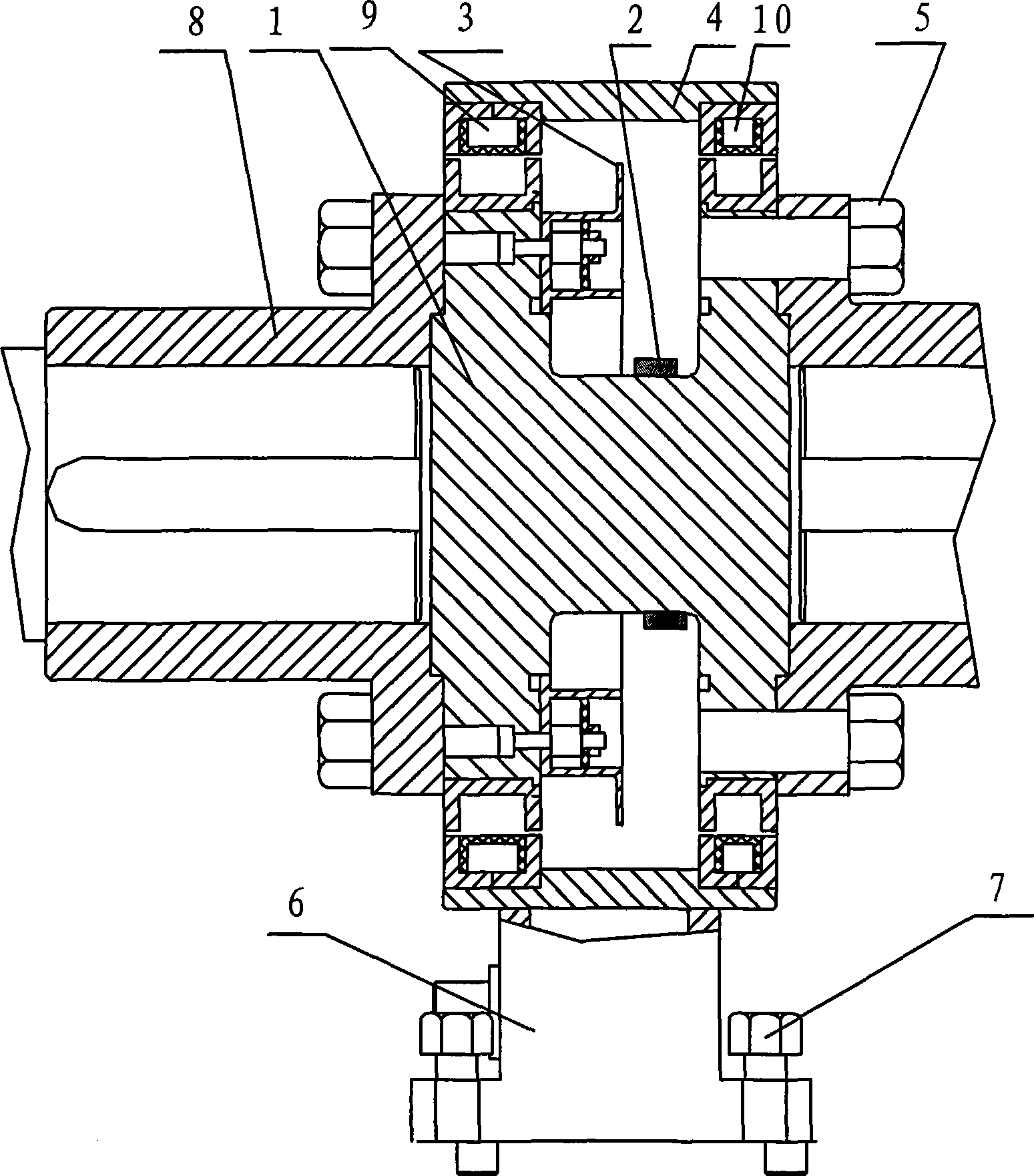

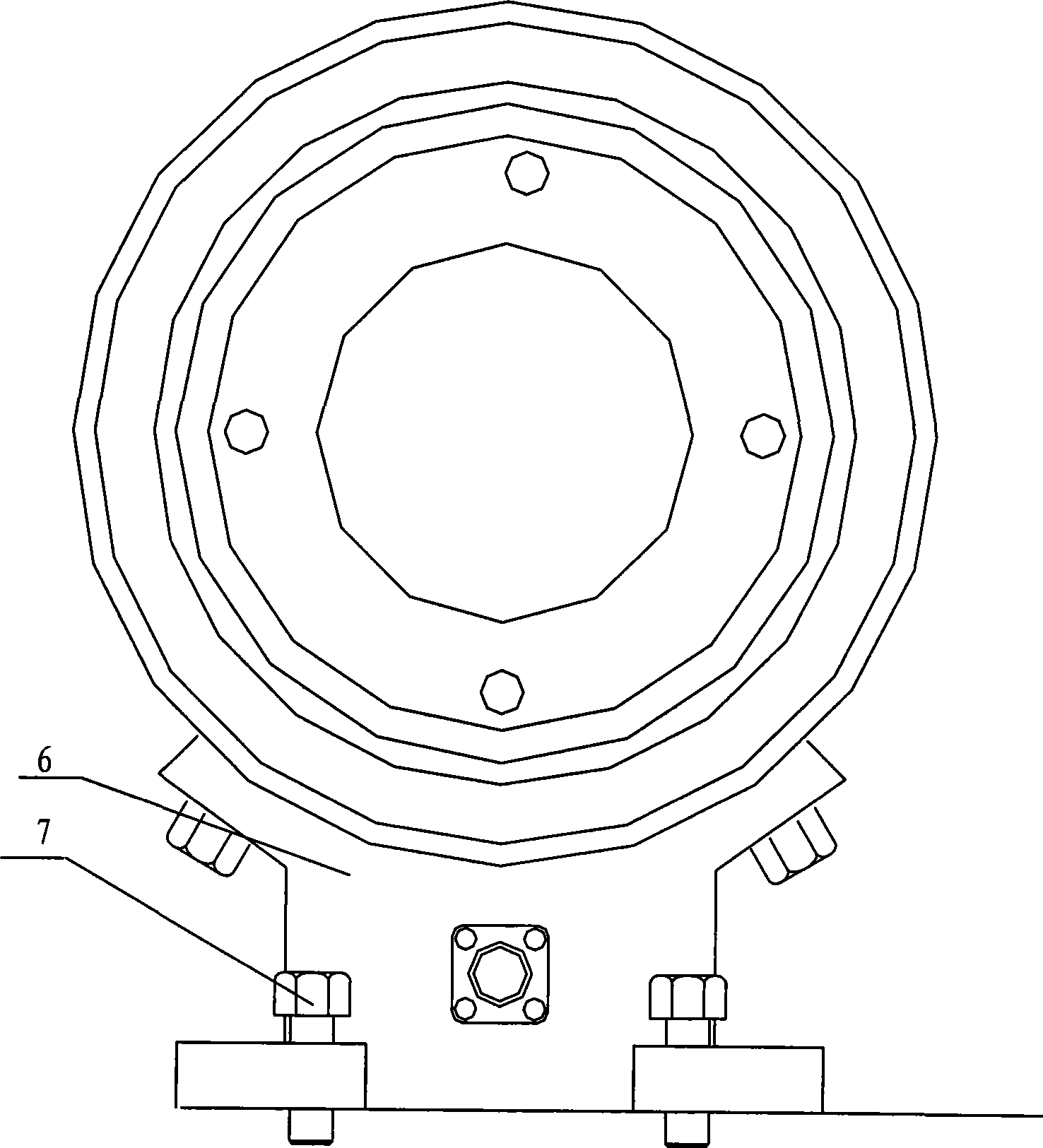

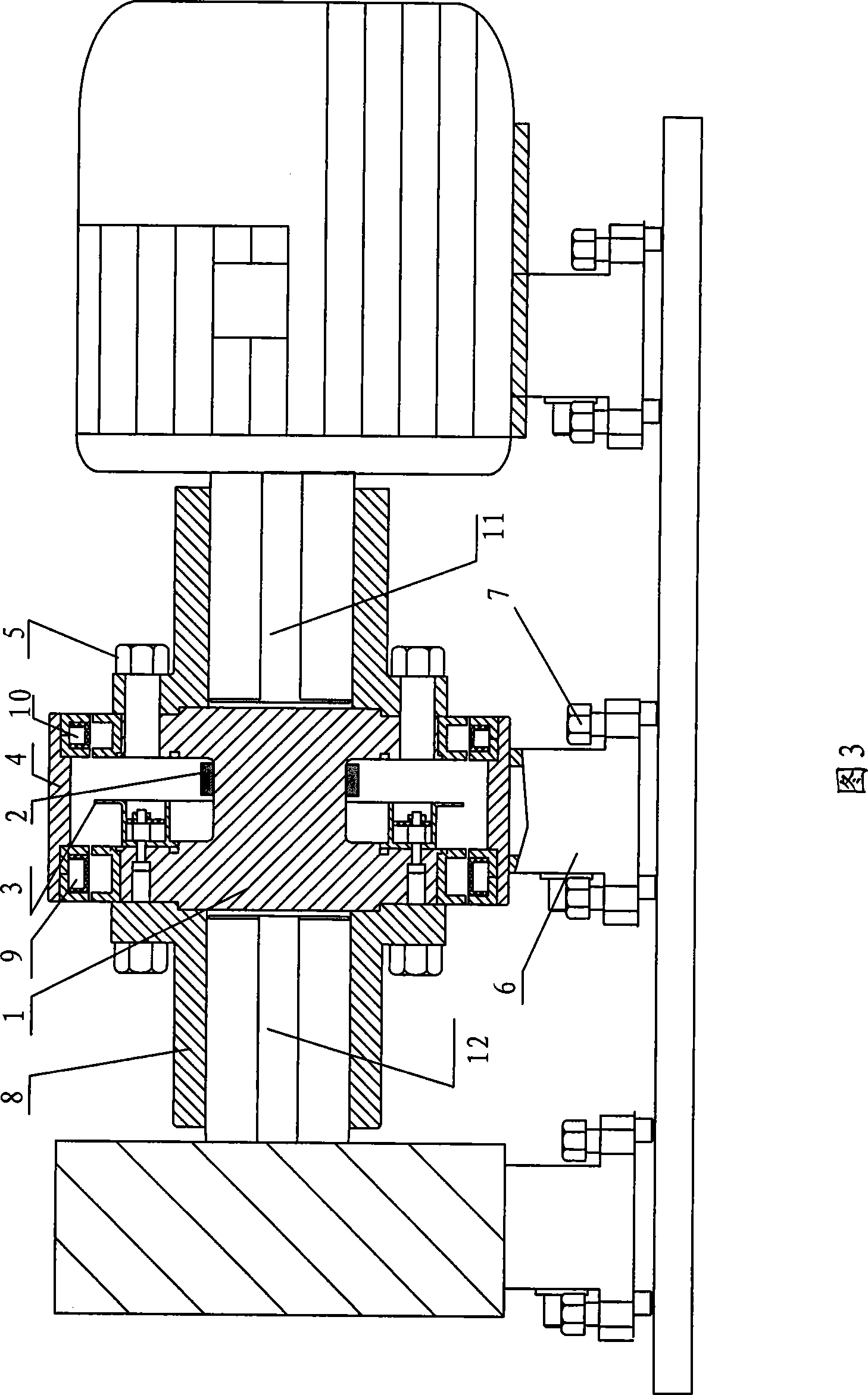

Method used

Image

Examples

Embodiment 2

[0026] The signal coupling transformer in the first embodiment of the measurement system of the torque sensor can be replaced by an optical coupling signal transmission device, and the non-contact transmission output of the torque measurement signal can also be realized. The specific working process is: the voltage signal output by the bridge is processed by signal processing After the circuit is processed, it is converted into a measurable voltage frequency signal. The voltage frequency signal will be transmitted to the optical coupling signal transmission device for coupling, and converted into a measurable optical frequency signal. The optical frequency signal can be directly output to the user's fixed receiver. The device realizes the non-contact signal transmission of the torque measurement signal, and finally obtains the torque value of the flange shaft 1.

[0027] In summary, the torque sensor of the present invention shortens the distance dimension in the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com