Thermal management method and device for micro dimension composite composite phase change cooling for automobile

A composite phase change and thermal management technology, applied in mufflers, exhaust devices, indirect heat exchangers, etc., can solve the problems of bulky volume, large gas passing pressure drop, low heat exchange efficiency of heat exchangers, etc. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

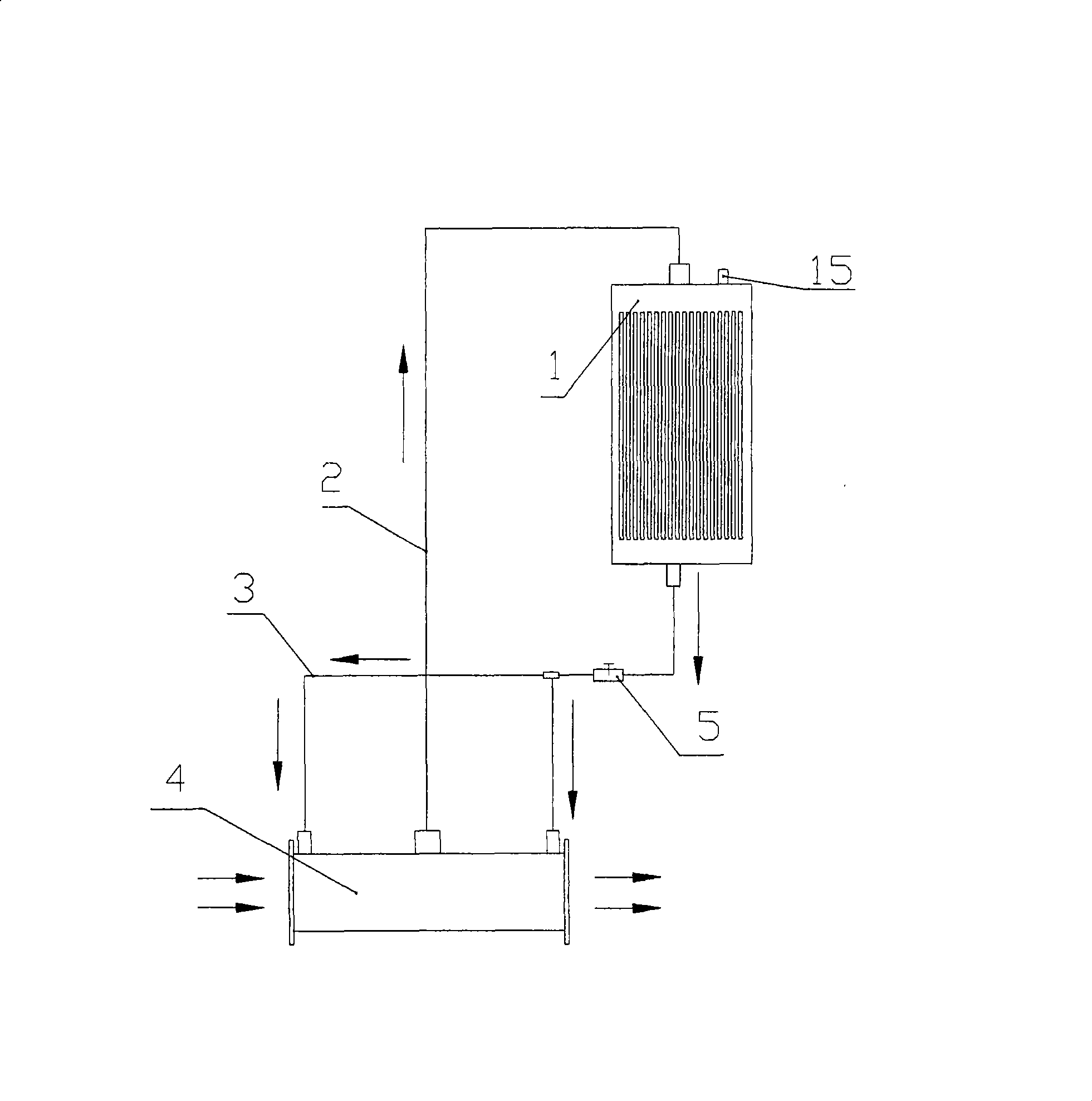

[0029] figure 1 Shown is a micro-scale composite phase change cooling vehicle thermal management device of the present invention, which is mainly composed of a heat absorption conversion device 4, a condenser 1, a steam insulation pipe 2, a liquid return pipe 3 and a solenoid valve 5. See figure 2 , the heat absorption conversion device 4 is formed by nesting two inner and outer metal round pipes 21, 22 with different diameters and the same length, and the two ends of the outer and inner round pipes 21, 22 are sealed and fixedly connected with a flange surface 23, and the inner round pipe 22 The inner cavity of the inner cavity is matched with the through holes on the two flange faces 23 to form a channel; the axes of the two circular tubes coincide after installation; the outer surface of the inner circular tube 22 is engraved with axial microgrooves (see image 3 ), the outer surface of the microgroove 24 is plated with a nano-film 29, and the outer surface is wrapped by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com