Electric motor valve

A technology of motor valve and valve cover, applied in the direction of valve details, valve device, valve housing structure, etc., can solve the problems of long-term stable operation of motor valve, affect the performance and accuracy of gas meter, and the failure of motor valve to close normally, etc., to achieve structural Reasonable and compact, reliable switching and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment, the present invention will be further elaborated in conjunction with accompanying drawing:

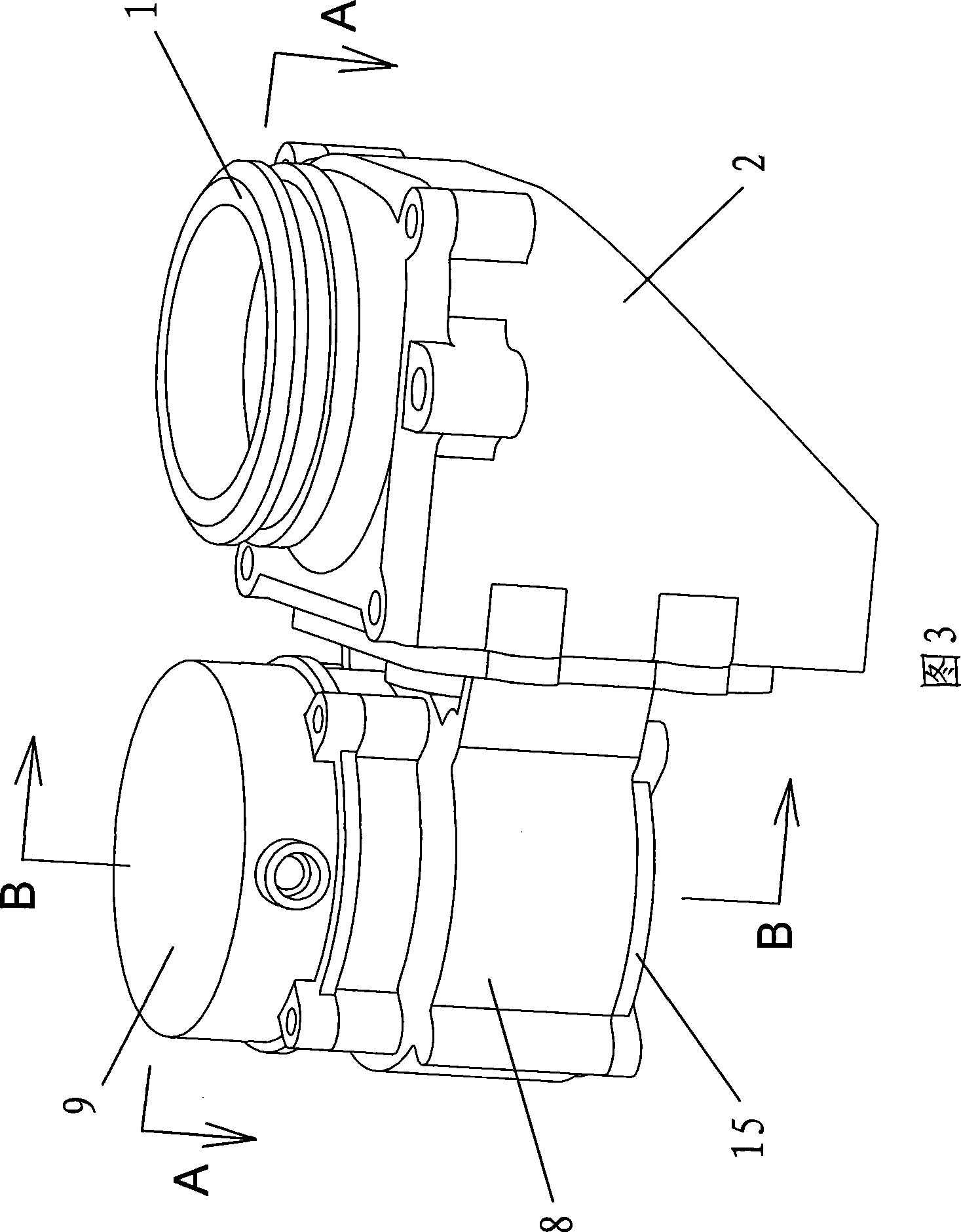

[0021] Referring to Fig. 3 to Fig. 6, the motor valve of the embodiment includes a valve body 2, a valve cover and an actuator assembly. The valve body 2 is provided with an air inlet 21 and an air outlet 22. The valve body 2 is a rectangular valve body with missing corners, and its air outlet 22 is set as an oblique air outlet. It can be designed to be 40-50° according to different usage requirements. In this embodiment, considering the easy position of the valve cover switch action and the size of the air outlet 22, the included angle is designed to be 42°; the air inlet 21 of the valve body 2 is fixed with a connection Plate 1, the connecting plate 1 is fixedly connected with the valve body 2 through screws, the connecting plate 1 undertakes the function of connecting with the gas meter, and the connecting plate 1 can be exchanged to make the motor valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com