Laser surface micro forming device and method

A surface micromodeling and laser technology, which is applied in laser welding equipment, optics, optical components, etc., can solve problems such as difficult processing, poor stability and reliability, and limited amount of material removal, so as to reduce wear and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 8 In this embodiment, the surface of the cylinder liner workpiece 35 in the cylinder liner workpiece / piston ring system is processed with micro-recessed cavities, or crossed micro-recessed cavities or a combination of both.

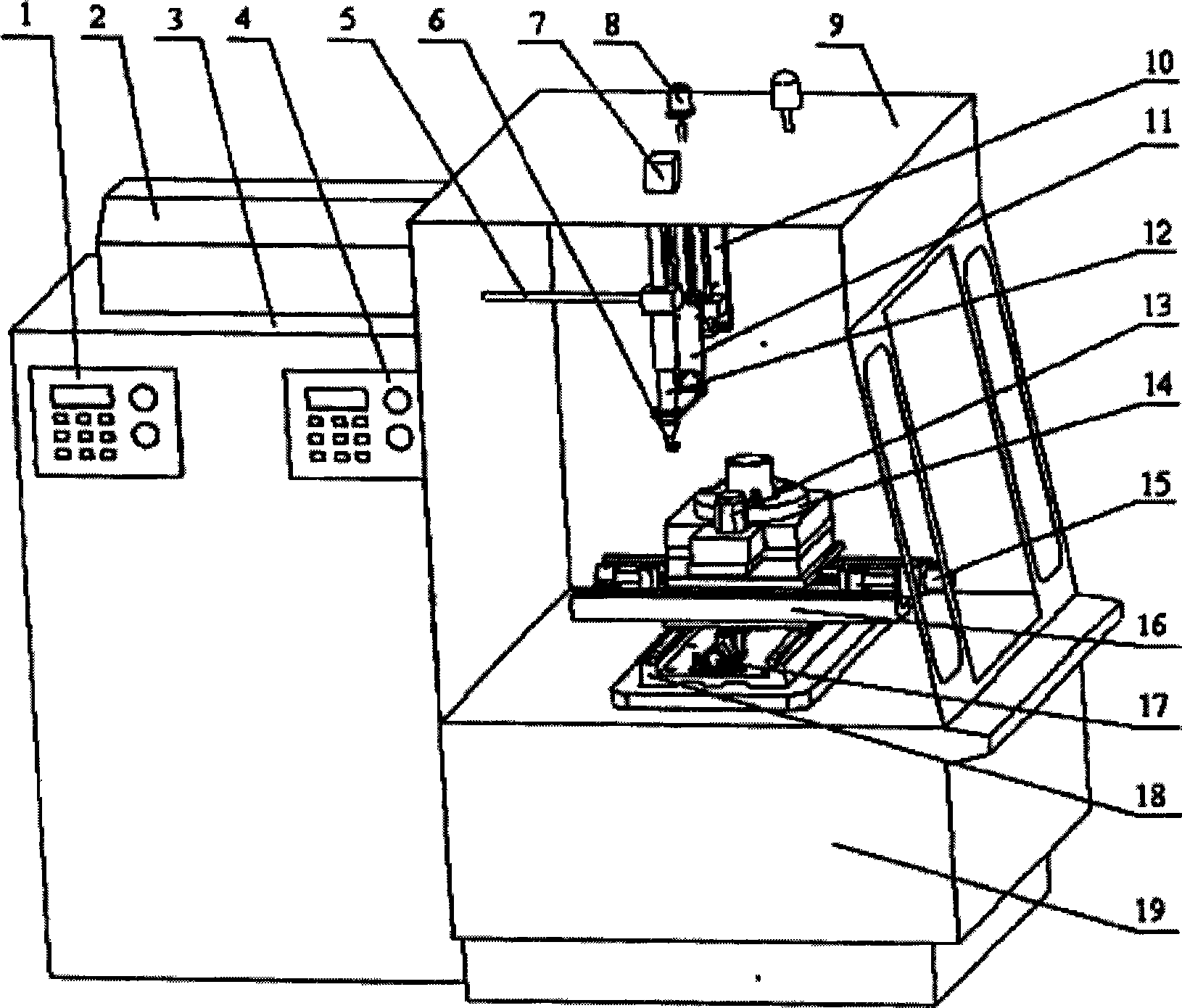

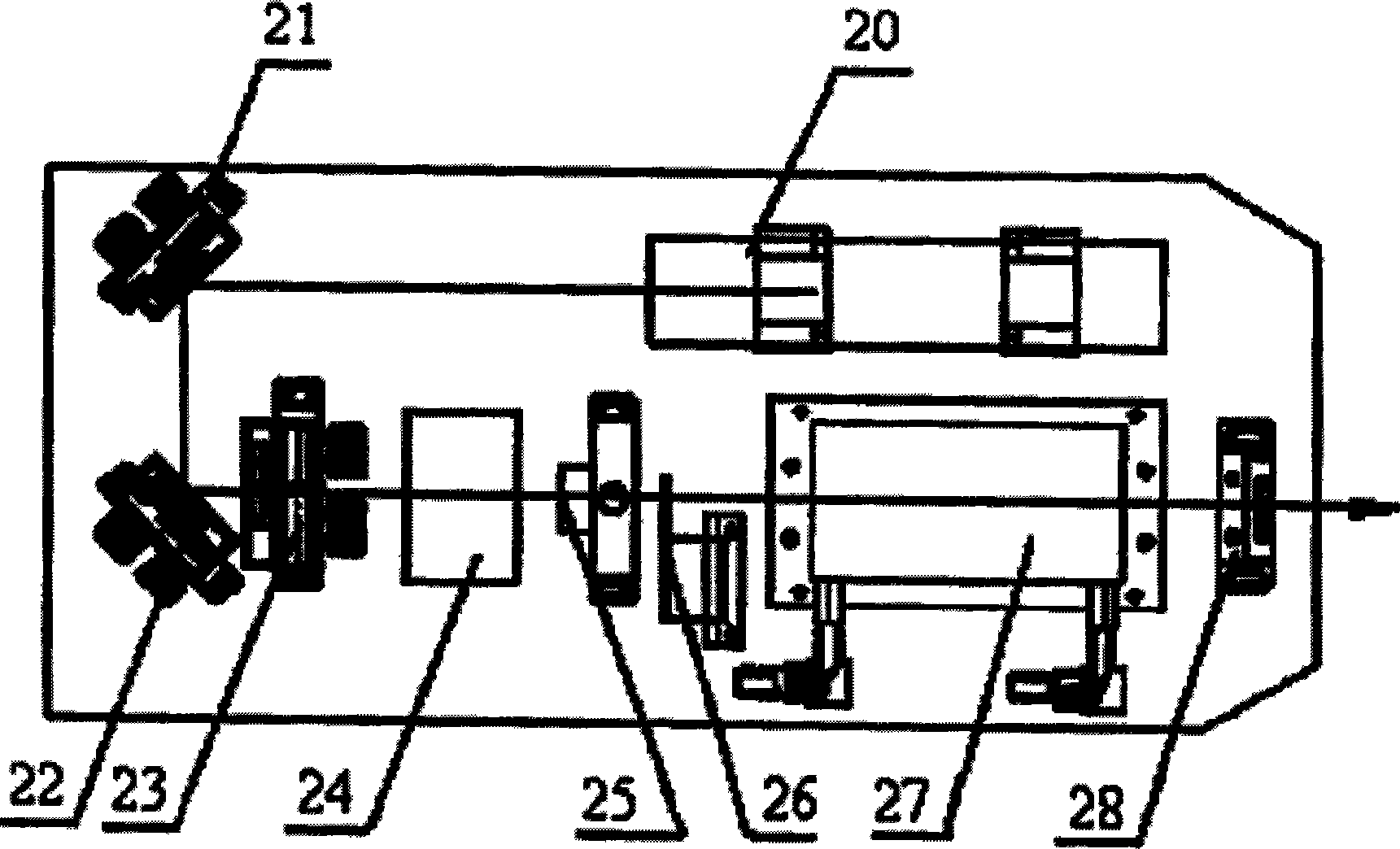

[0039] A flat base 19 is used to fix the X-direction guide rail 18 on it. The servo motor 17 of the model MSMA102A1G drives the Y-direction guide rail platform to move left and right along the guide rail 18 through the ball screw; the servo motor 15 of the model MSMA102A1G drives the turntable through the ball screw Move back and forth along the guide rail 16; the servo motor 13 of the model MSMA102A1C drives the main shaft 14 to rotate through the belt drive, and an incremental encoder of the type 1fa-500a-25000 is installed in the coaxial direction of the main shaft 14; the servo of the model is MSMA022A1A The motor 8 drives the telescopic frame 11 to move up and down along the Z-direction vertical guide rail 10 through the ball s...

Embodiment 2

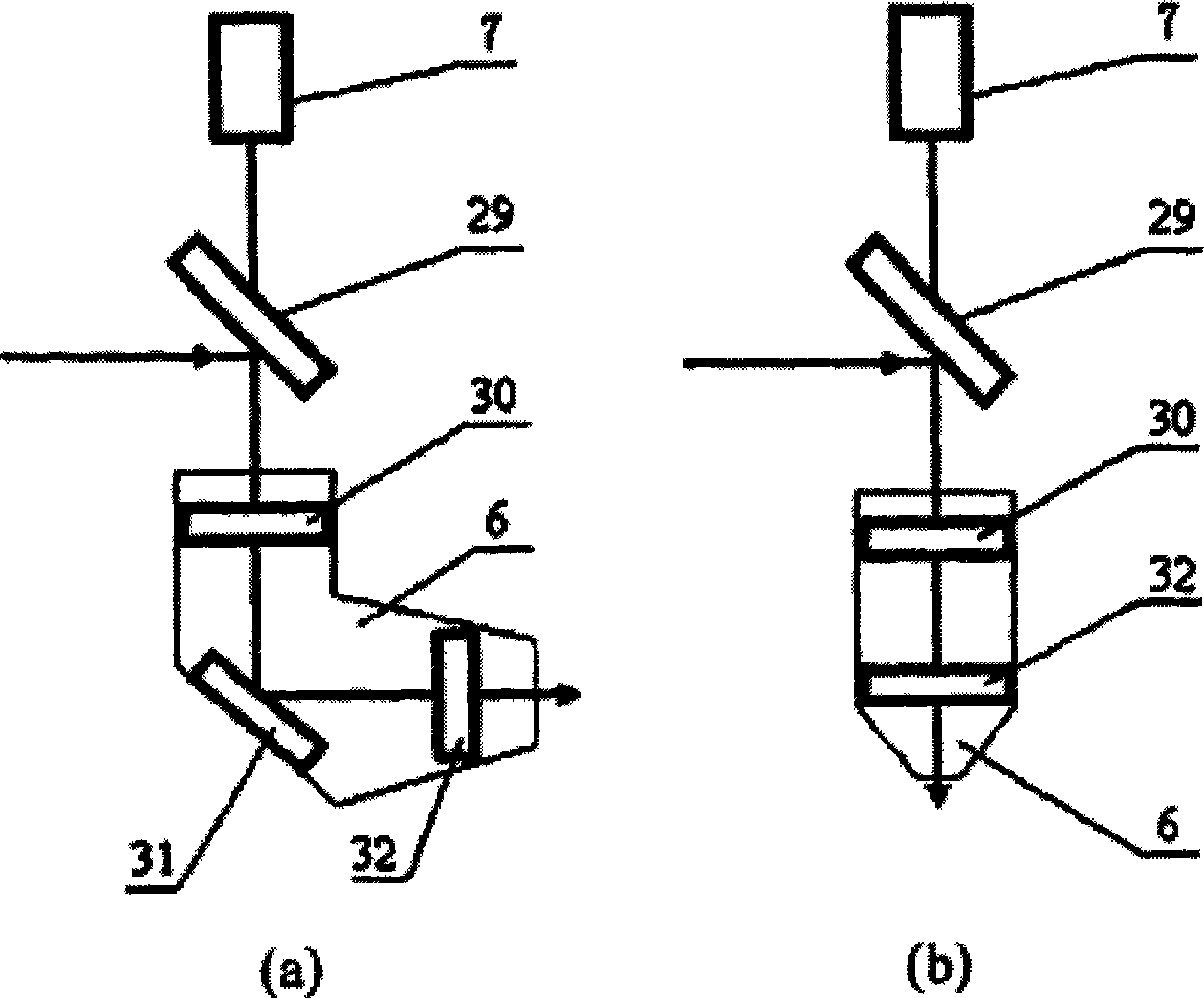

[0046] Such as Figure 10-12 As shown, the micro-cavity 39 and the micro-groove 38 are processed on the zero-leakage non-contact new mechanical seal ring workpiece 36. The basic principle is the same as the processing of the cylinder liner workpiece 35 in Embodiment 1, except that the end face of the seal ring is flat. So the laser processing nozzle consists of image 3 The elbow in (a) becomes image 3 Straight head in (b). Such as Figure 11 , when processing wide spiral grooves 40 with a depth of 1um to 20um and a width of more than 1mm, it can be completed by overlapping the concave cavities into narrow grooves, and then overlapping the narrow grooves into wide grooves , the shape of this macroscopic shallow groove, such as arc groove, spiral groove, etc., can be realized by the control software.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com