Gallium indium aluminum low congruent melting molten mass and use thereof in air purification

A melt and eutectic technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the working life of the bubbler and failing to meet the requirements of gas purity, and achieve the improvement of purification efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Test method

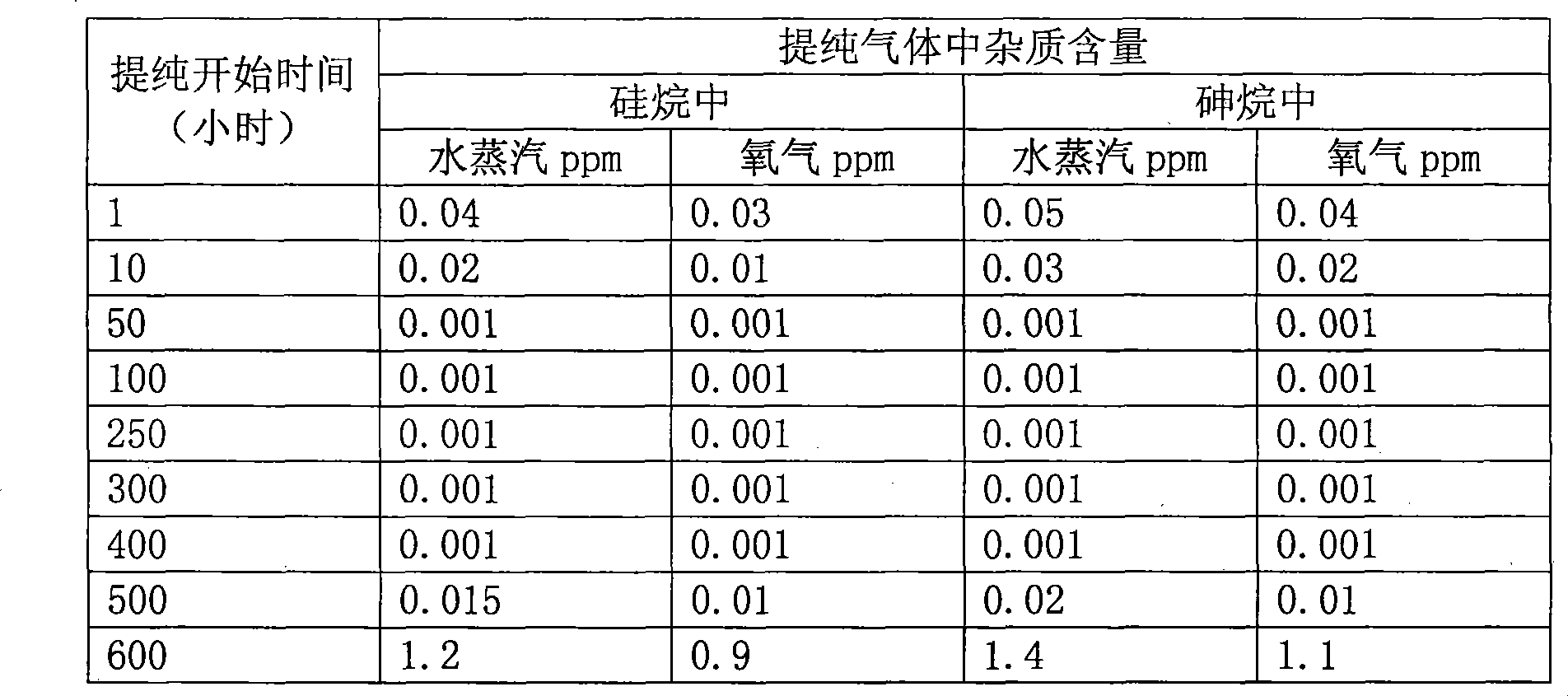

[0014] (1) At room temperature, add 300 grams of gallium, 30 grams of indium, 15.59 grams of mercury, and 16.5 grams of aluminum into the bubbler, and a liquid melt will be formed in almost an hour; 12ppm water vapor, 10ppm oxygen silane; the impurity content in the gas was measured at different time points, and the test results are shown in Table 1.

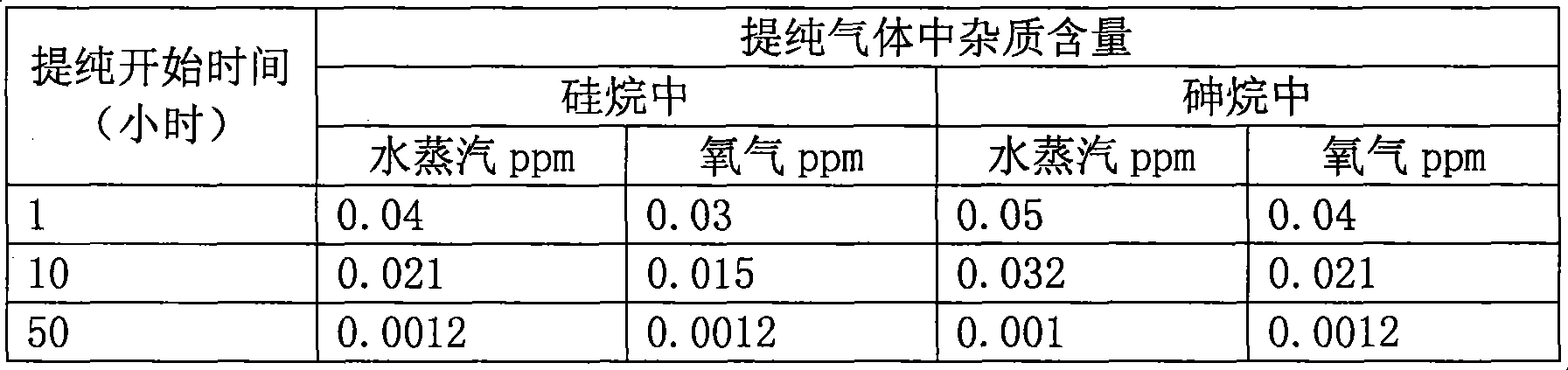

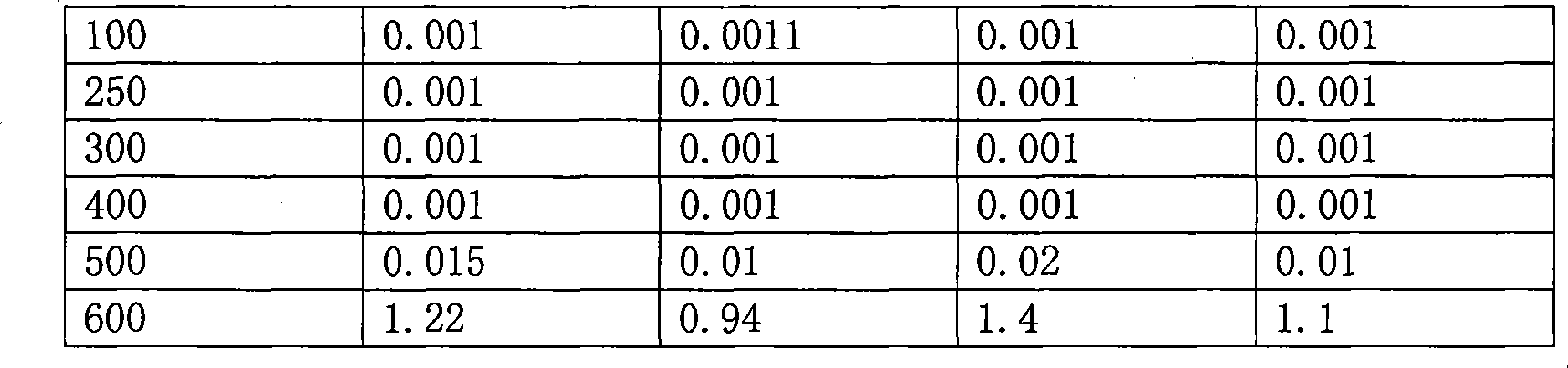

[0015] (2) At room temperature, add 300 grams of gallium, 30 grams of indium, 13.86 grams of mercury, and 16.5 grams of aluminum into the bubbler, and a liquid melt will be formed in almost an hour; The arsine of water vapor and 12ppm oxygen; the impurity content in the gas was measured at different time points, and the test results are shown in Table 2.

[0016] (3) At room temperature, add 300 grams of gallium, 30 grams of indium, 17.325 grams of mercury, and 16.5 grams of aluminum into the bubbler, and a liquid melt will be formed in almost an hour; Water vapor and 12ppm oxygen arsine; the impurity c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com