Technique of applying temperature-sensing discolored ink in noble metal coin (badge)

A thermochromic ink and precious metal technology, applied in the field of coin manufacturing, can solve the problems of not being able to directly print metal products, not involving the application of thermochromic ink, etc., to increase anti-counterfeiting performance, enrich artistic expressions, and improve ornamental and collection. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

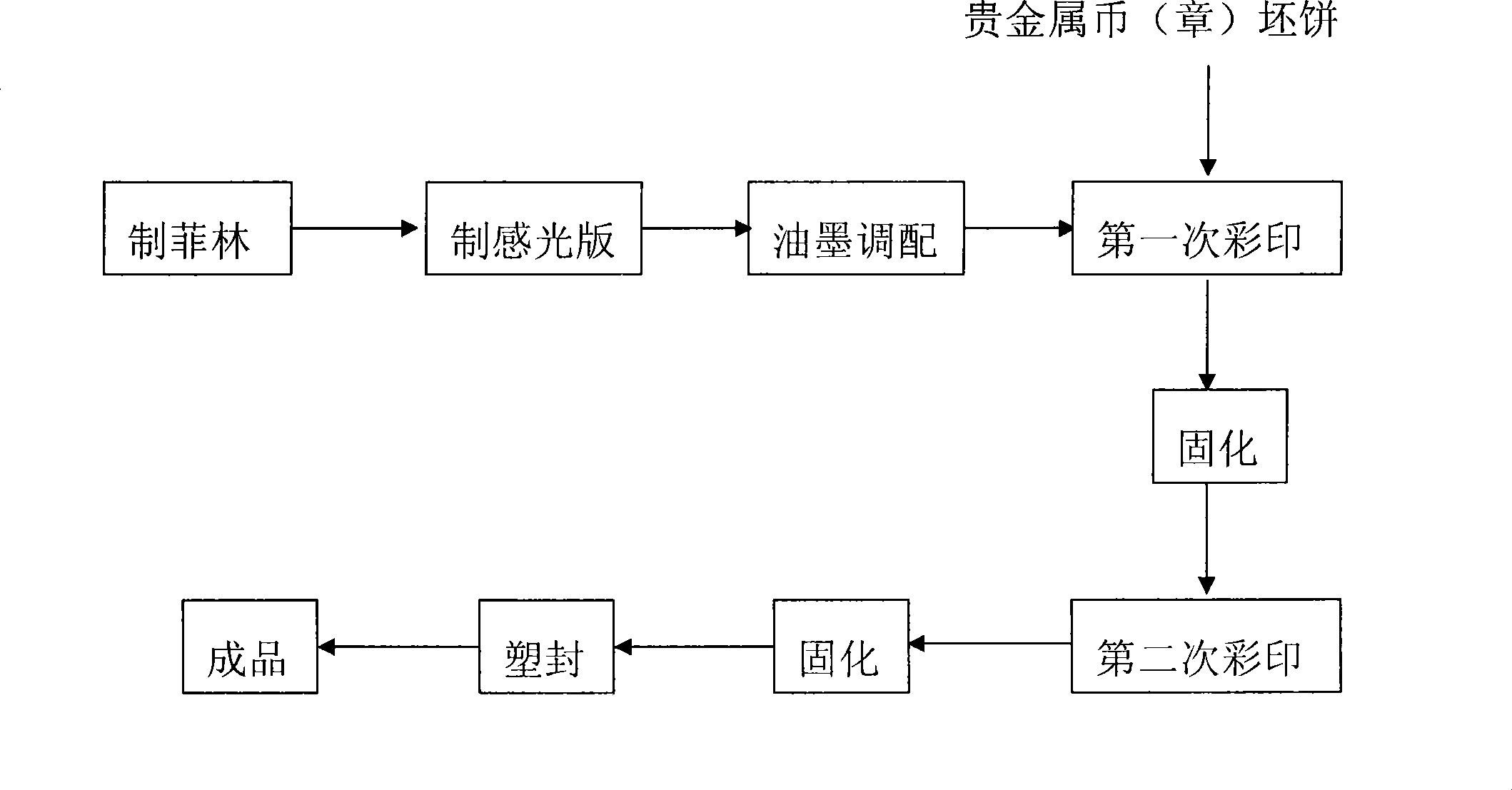

[0020] See attached figure 1 , the present invention carries out overlay color printing to the embossed precious metal coin (chapter) base cake with temperature-sensitive discoloration ink and metal ink, vacuum plastic seals after secondary color printing, solidification, specifically carries out according to the following steps:

[0021] 1. Making film

[0022] (1) Determine the anti-counterfeit printing and non-anti-counterfeiting printing parts according to the specific situation, and make different films according to different printing methods;

[0023] (2) According to the characteristics of the pad printing process, the adjustment of the different tone curves and the precise alignment of the embossed position of the blank cake are carried out within the range of 60% of the dots for the electronic files that need to be color printed, so as to meet the requirements of the color printing process;

[0024] (3) Carry out laser color separation processing on the adjusted elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com