Formula of acetate starch and preparation technique thereof

A technology of acetate starch and formulation, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems of low production efficiency and low starch DS value, achieve the effect of improving quality and level, excellent size film performance, and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

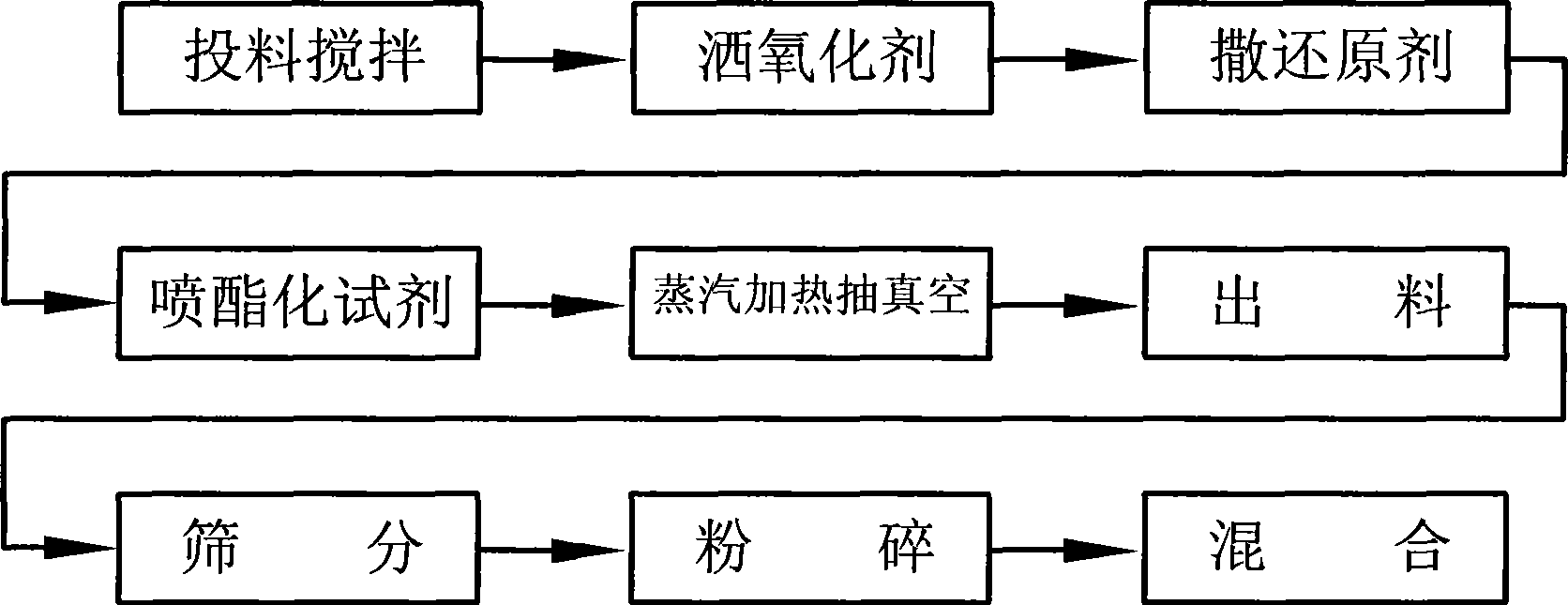

[0038] Feed and add various reagents according to the formula listed in Table 1, and operate according to the following procedures: Feed and stir: add corn starch, caustic soda and alcohol to the material box, and stir for 15 minutes; Sprinkle oxidant: Sprinkle oxidant, the temperature will rise naturally. Control, react under normal pressure conditions for 35 minutes; sprinkle reducing agent: disperse and sprinkle powdered reducing agent to destroy the oxidizing agent in the reaction system, and react for 15 minutes; spray esterification reagent: spray into liquid esterification reagent, react for 65 minutes, during the reaction If the temperature rises above 60°C, use a cooling water pipe to reduce the reaction temperature; steam heating and vacuuming: when the reaction time reaches 70 minutes, use steam to heat to 65°C and continue vacuuming to completely evaporate and recover the alcohol in the material box. Then discharge, sieve, pulverize and mix to complete the whole pro...

Embodiment 2

[0040] Feed and add various reagents according to the formula listed in Table 1, operate according to the following procedures: Feed and stir: add corn starch, caustic soda and alcohol to the material box, and stir for 11 minutes; Sprinkle oxidant: sprinkle oxidant, the temperature will rise naturally. Control, react under normal pressure conditions for 30 minutes; sprinkle reducing agent: disperse and sprinkle powdery reducing agent to destroy the oxidizing agent in the reaction system, react for 15 minutes; spray esterification reagent: spray into liquid esterification reagent, react for 70 minutes, during the reaction When the temperature rises above 60°C, use a cooling water pipe to lower the reaction temperature; steam heating and vacuuming: when the reaction time reaches 60 minutes, use steam to heat to 65°C and continue vacuuming to completely evaporate the alcohol in the material box and recover it by distillation. Discharging, sieving, crushing, and mixing complete the...

Embodiment 3

[0042] Feed and add various reagents according to the formula listed in Table 1, and operate according to the procedure of Implementation 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com