High discharge system for loose unpacked material

A bulk material, high-level technology, applied in loading/unloading, packaging, conveyor objects, etc., can solve the problems of dry mortar segregation, limit the development of dry mixed mortar in bulk, etc., to prevent material segregation, reduce and control material segregation, The effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

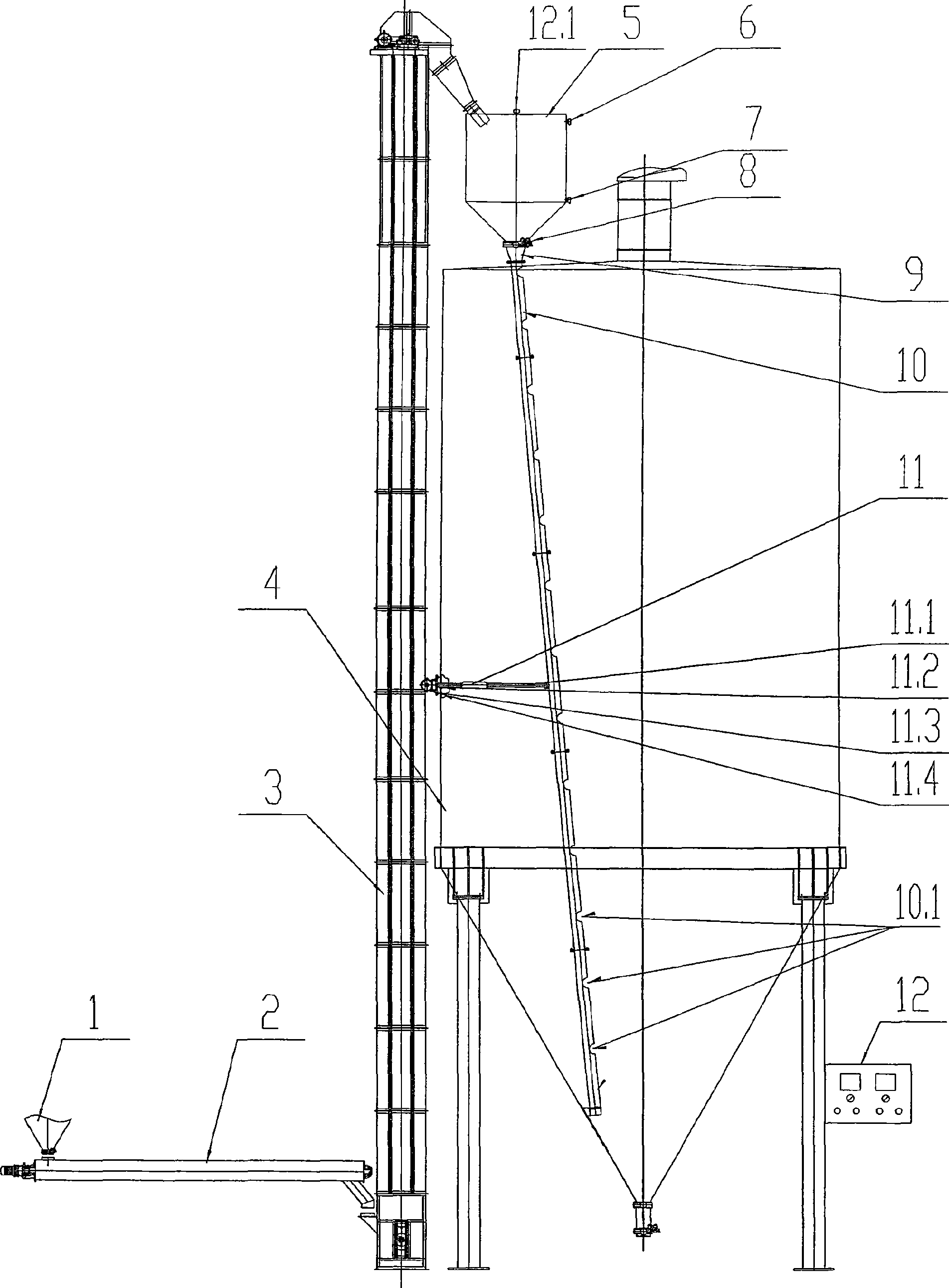

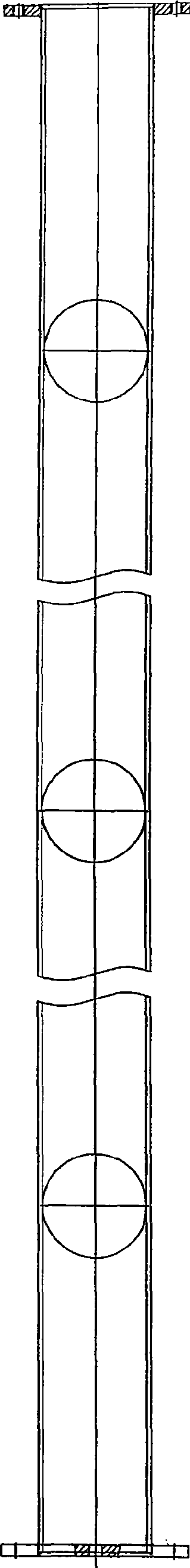

[0019] See figure 1 , The bulk material high-level unloading system of the present invention is mainly composed of mixer unloading hopper 1, horizontal screw conveyor 2, vertical bucket elevator 3, transition silo 5, conical transition hopper 9, bulk silo 4, unloading The pipe 10, the pigging device 11 and the automatic control device 12 are composed. The mixer discharge hopper 1 is arranged above the horizontal screw conveyor 2. The discharge port of the mixer discharge hopper 1 is connected with the feed port of the horizontal screw conveyor 2, and the vertical bucket elevator 3 is placed on the horizontal screw conveyor. On the rear side of the machine 2, the feed port at the lower part of the vertical bucket elevator 3 is connected with the discharge port of the horizontal screw conveyor 2, and the transition silo 5 is arranged on the rear side of the upper discharge port of the vertical bucket elevator 3 The upper and lower material level detector 6 and the lower material le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com