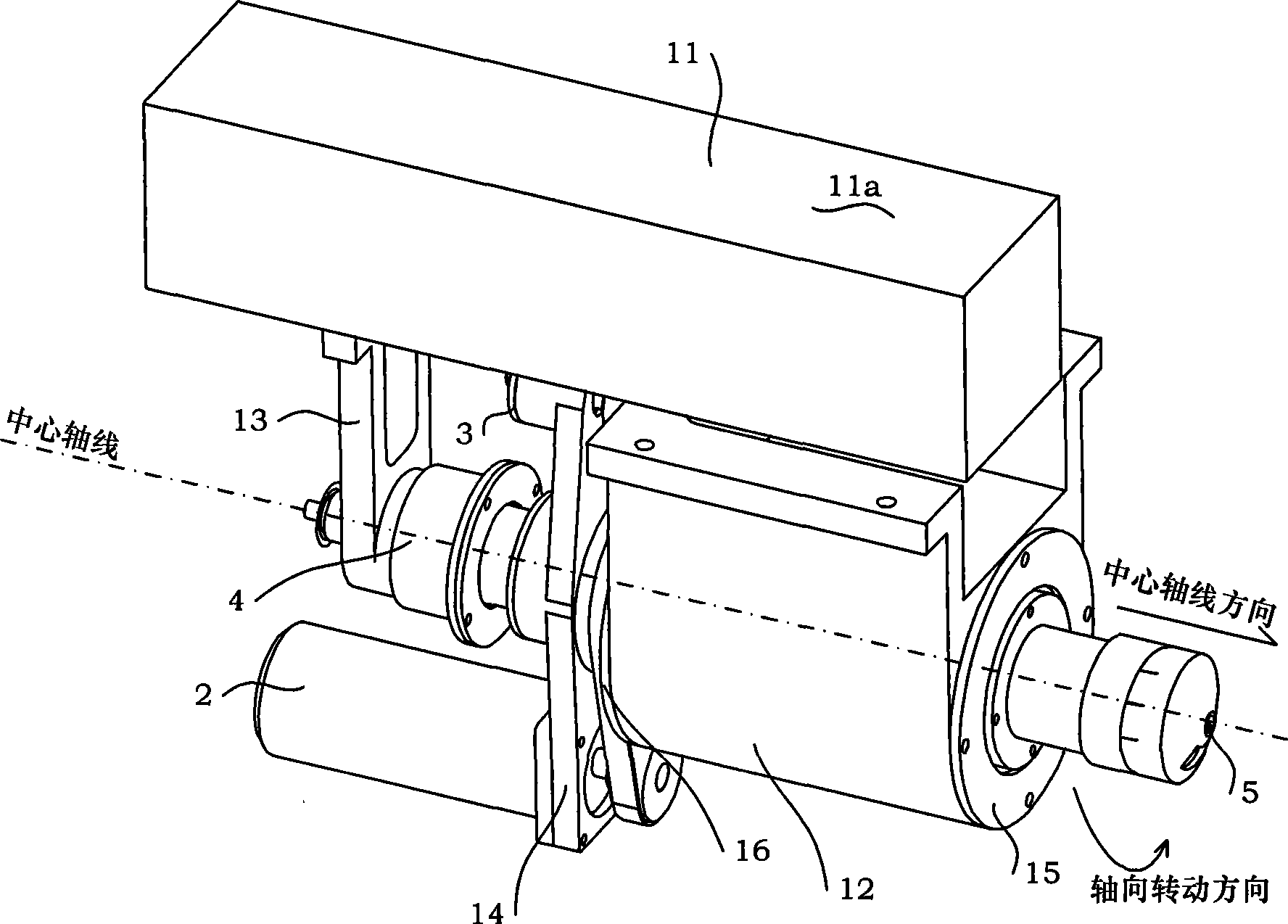

Floating type oval-shaped supersonic vibration micro-engraving device

An ultrasonic vibration, floating technology, applied in the direction of driving device, fluid using vibration, large fixed members, etc., can solve the problems of low precision of micro-grooves, difficult to control the cross-sectional shape of micro-grooves, low precision of groove width, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

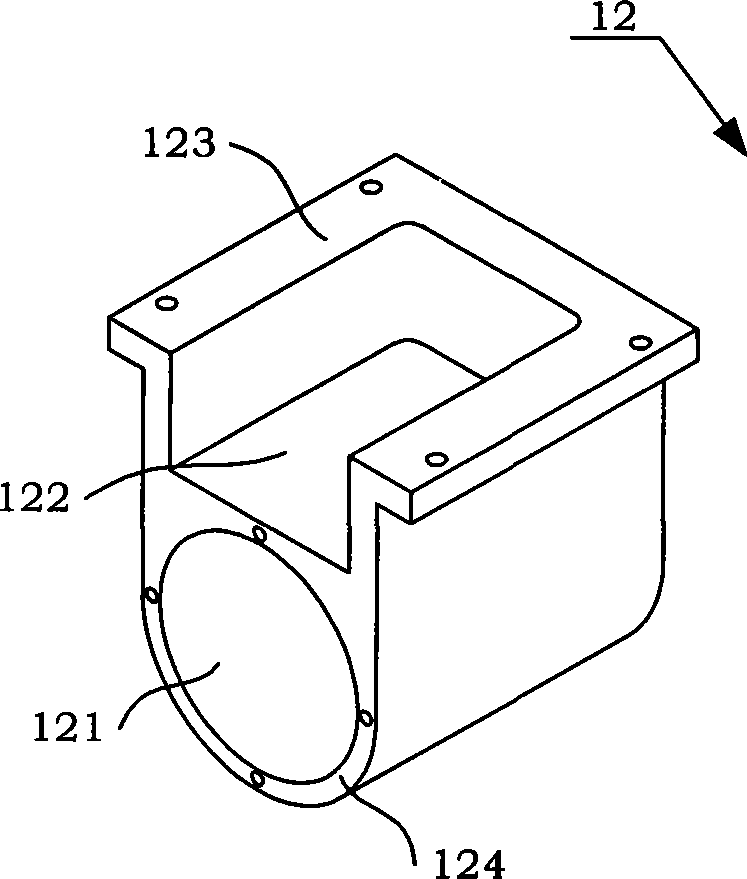

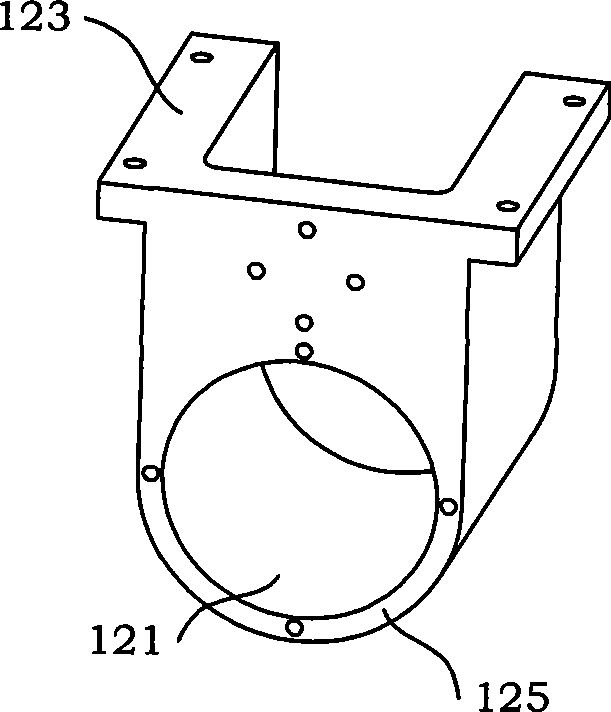

[0026] The floating elliptical ultrasonic vibration micro-engraving device of the present invention can generate elliptical ultrasonic vibration to realize micro-engraving under the drive of an ultrasonic transducer. The micro-engraving device of the present invention uses the floating transducer assembly to ensure that the depth of the processed groove remains constant; and then uses the longitudinal bending transducer to make the tool generate ultrasonic elliptical vibration, and cutting with the help of ultrasonic elliptical vibration can reduce cutting force, improve processing accuracy and reduce The characteristics of surface roughness to ensure that the groove on the surface of the machined part has high geometric accuracy and surface quality and the edge is free of burrs; the combined design of the longitudinal bending transducer and the drive unit mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com