Method for preparing coaxial microchannel reactor

A microchannel reactor, coaxial technology, applied in the field of microfluidics, can solve problems such as time-consuming, channel damage, and difficulty in sealing, and achieve the effect of less time-consuming, low cost, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

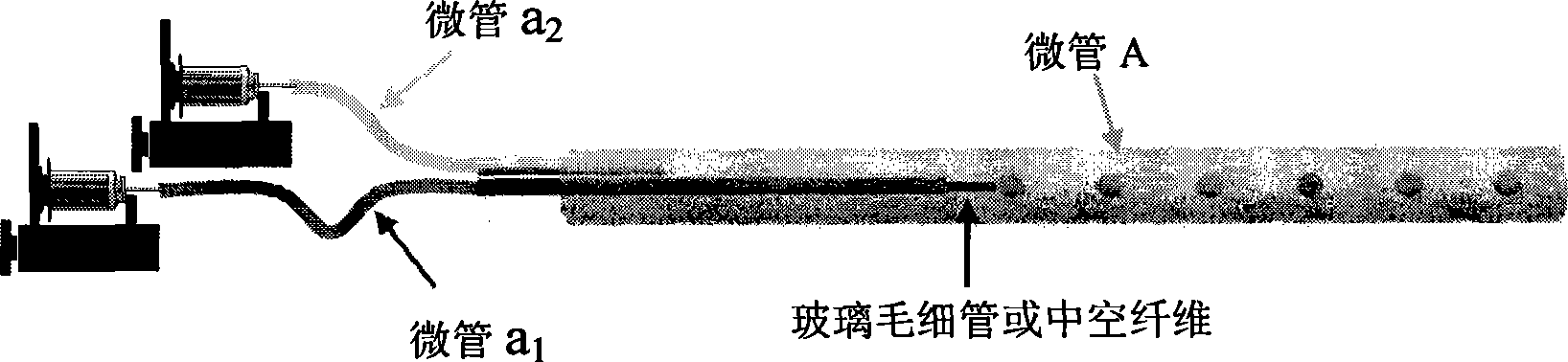

[0030] Take a polytetrafluoroethylene microtube A with an inner diameter of 1.6 mm and a length of 40 cm, and two microtubes a with an inner diameter of 300 μm and an outer diameter of 700 μm and a length of 30 cm 1 and a 2 ; put a 1 、a 2 The microtube is placed into tube A, where a 1 Placed at the central axis of tube A, the length into tube A is 16cm; a 2 The length that enters the tube A is 4 cm; seal and fix the microtube with epoxy resin, and place the microtube a in the microchannel device 1 and a 2 Connect with two syringes placed on the syringe pump respectively to obtain a coaxial microchannel reactor, such as figure 1 shown.

[0031] Use a syringe pump to inject the polylactic acid solution and polyvinyl alcohol solution, which are the raw materials for preparing polymer microspheres, into the microchannel reaction device at a concentration of 0.05 g / mL and 0.015 g / mL respectively. A small amount of red oily dye is added to the polylactic acid solution, The pu...

Embodiment 2

[0033] Take a polytetrafluoroethylene microtube A with an inner diameter of 1.8 mm and a length of 50 cm, and two microtubes a with an inner diameter of 400 μm and an outer diameter of 800 μm and a length of 50 cm 1 and a 2 ; in microtubule a 1 A section of glass capillary with an inner diameter of 200 μm and a length of 5 cm is sealed at the head of the tube A; 1 、a 2 The microtube is placed into tube A, where a 1 Placed at the central axis of tube A, the length into tube A is 18cm, a 2 The length that enters the tube A is 5 cm; seal and fix the microtube with epoxy resin, and place the two thinner microtubes a in the microchannel device 1 and a 2 They are respectively connected with two syringes placed on the syringe pump to obtain a coaxial microchannel reactor.

[0034] Use a syringe pump to inject the polylactic acid solution and polyvinyl alcohol solution, which are the raw materials for preparing polymer microspheres, into the microchannel reaction device. / min, ...

Embodiment 3

[0037] Take a polytetrafluoroethylene microtube A with an inner diameter of 1.2 mm and a length of 50 cm, and two microtubes a with an inner diameter of 200 μm and an outer diameter of 400 μm and a length of 40 cm 1 and a 2 ; in microtubule a 1 A section of polypropylene hollow fiber with an inner diameter of 120 μm and a length of 5 cm is sealed at the head of the tube to be inserted into the tube A;1 、a 2 The microtube is placed into tube A, where a 1 Placed at the central axis of tube A, the length into tube A is 14cm, a 2 The length that enters into tube A is 3 cm; seal and fix the microtube with epoxy resin, and place the two thinner microtubes a in the microchannel device 1 and a 2 They are respectively connected with two syringes placed on the syringe pump to obtain a coaxial microchannel reactor.

[0038] Use a syringe pump to inject the polylactic acid solution and polyvinyl alcohol solution, which are the raw materials for preparing polymer microspheres, into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com