A kind of tenderization processing method of dried meat

A processing method and tenderization technology, which is applied in meat tenderization, processed meat, slaughtering, etc., can solve the problems of long processing time, unsuitable control of the degree of enzymatic hydrolysis, and easy oily products, so as to improve the tissue structure and taste, The effect of controlling the degree of tenderization of dried meat and reducing the production of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

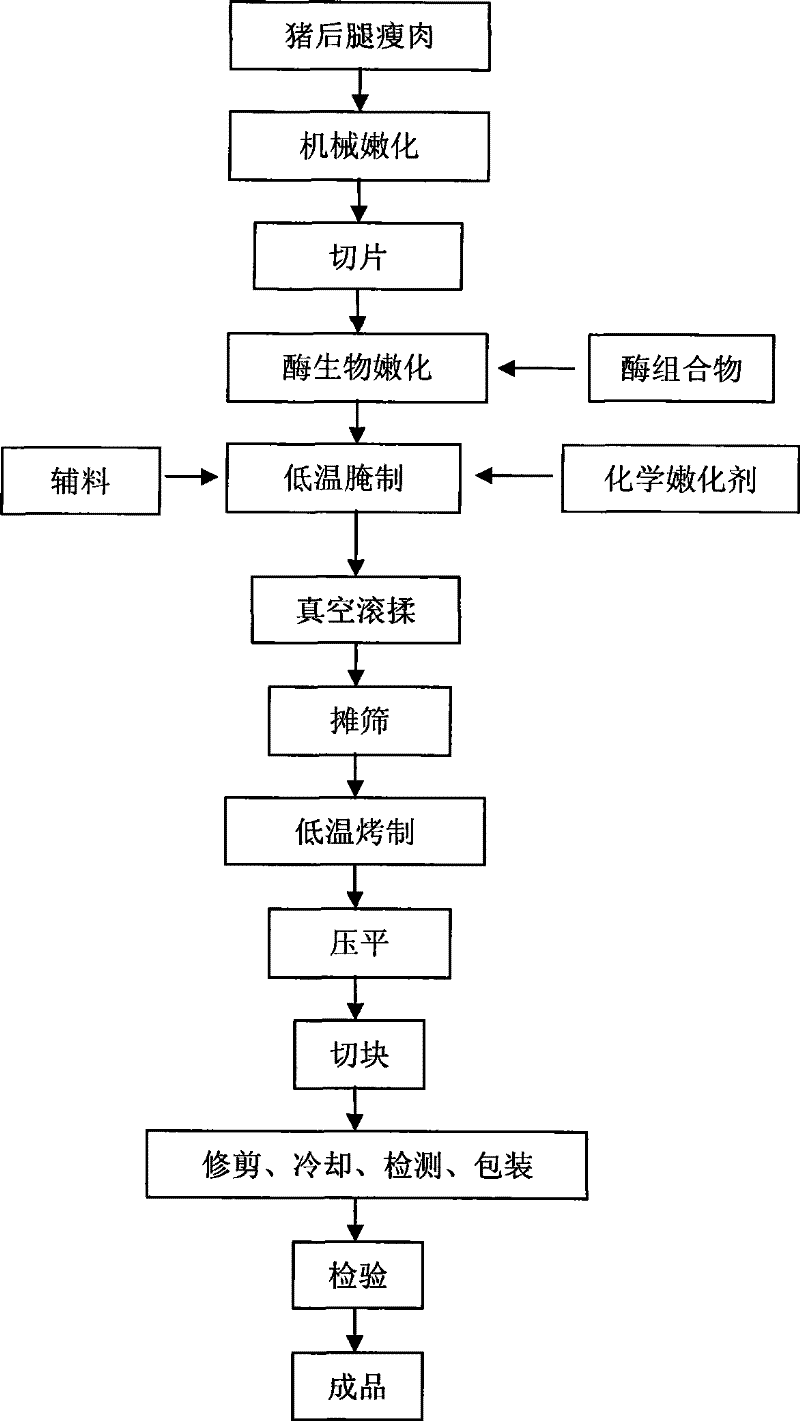

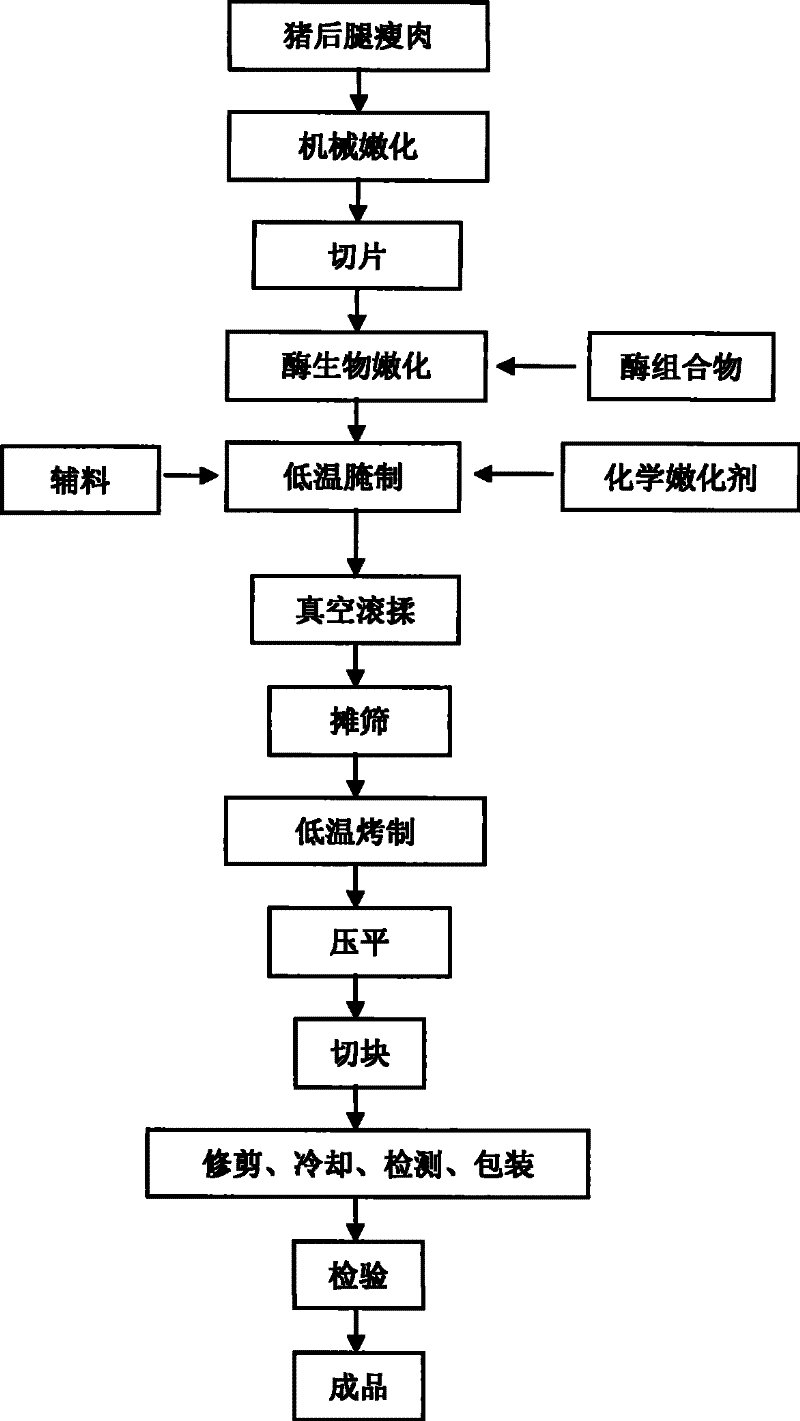

[0010] exist figure 1 , take 100 kg of cold fresh pork hind leg lean meat, use the stainless steel tenderizing knife installed on the saline injection machine to regularly cut off the muscle fibers in the lean meat; then use a slicer to cut the meat into 3mm thick thin meat slices; adding a mass ratio of 1:2500 containing the composition of the enzyme mixture to treat the meat slices for 2 minutes, wherein the enzyme mixture contains 65% bromelain, 25% papain and 10% ginger protease, the amount of the enzyme mixture accounts for 20% of the composition, the amount of the carrier β-cyclodextrin accounts for 80% of the composition; after enzymolysis, add 0.35 kg of complex phosphate, 0.4 kg of calcium chloride and 20 kg of various auxiliary materials, the auxiliary materials are salt, sucrose , eggs, fish marinade, monosodium glutamate, pepper, five-spice powder, nitrite, and other liquid or powdery seasonings made from natural seasonings; marinate and Vacuum tumbling, the vacuu...

Embodiment 2

[0012] exist figure 1 , take 100 kg of cold fresh pork hind leg lean meat; use the stainless steel tenderizing knife installed on the saline injection machine to regularly cut off the muscle fibers in the lean meat; then use a slicer to cut the meat into 2mm Thick slices; add a composition containing an enzyme mixture with a mass ratio of 1:2000 to treat the meat slices for 1.5 minutes, the amount of the enzyme mixture accounts for 15% of the composition, and the amount of the carrier β-cyclodextrin accounts for 85% of the composition, wherein the enzyme The mixture contains 55% bromelain, 30% papain and 15% ginger protease. After enzymolysis, 0.3 kg of complex phosphate, 0.3 kg of calcium chloride and 16 kg of various auxiliary materials are added. The auxiliary materials are Salt, sucrose, eggs, fish brine, monosodium glutamate, pepper, five-spice powder, nitrite, and other liquid or powdery seasonings made from natural seasonings or a mixture of several of them; at a low te...

Embodiment 3

[0014] exist figure 1 , take 100 kg of cold fresh pork hind leg lean meat; use the stainless steel tenderizing knife installed on the saline injection machine to regularly cut off the muscle fibers in the meat; cut the meat with a slicer into thin slices with a thickness of 4 mm; add a composition containing an enzyme mixture with a mass ratio of 1:3000 to treat the meat slices for 3 minutes, the amount of the enzyme mixture accounts for 25% of the composition, and the amount of the carrier β-cyclodextrin accounts for 75% of the composition, Wherein the enzyme mixture comprises 70% bromelain, 15% papain and 15% ginger protease, after enzymolysis, add 0.4 kg of compound phosphate, 0.45 kg of CaCl2 and 23 kg of various auxiliary materials, auxiliary materials are salt, sucrose , eggs, fish marinade, monosodium glutamate, pepper, five-spice powder, nitrite, and other liquid or powdery seasonings made from natural seasonings; marinate and Vacuum tumbling, the vacuum degree is 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com