Nonwoven-fabric laminate, moisture-permeable nonwoven-fabric laminated sheet comprising nonwoven-fabric laminate, and sanitary supply employing these

A technology for non-woven fabrics and hygiene products, applied in the directions of non-woven fabrics, layered products, textiles and paper making, etc., can solve the problems of poor softness and insufficient hygiene products, and achieve high flexibility and prevent hot melt. The effect of adhesive contamination and soft use feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

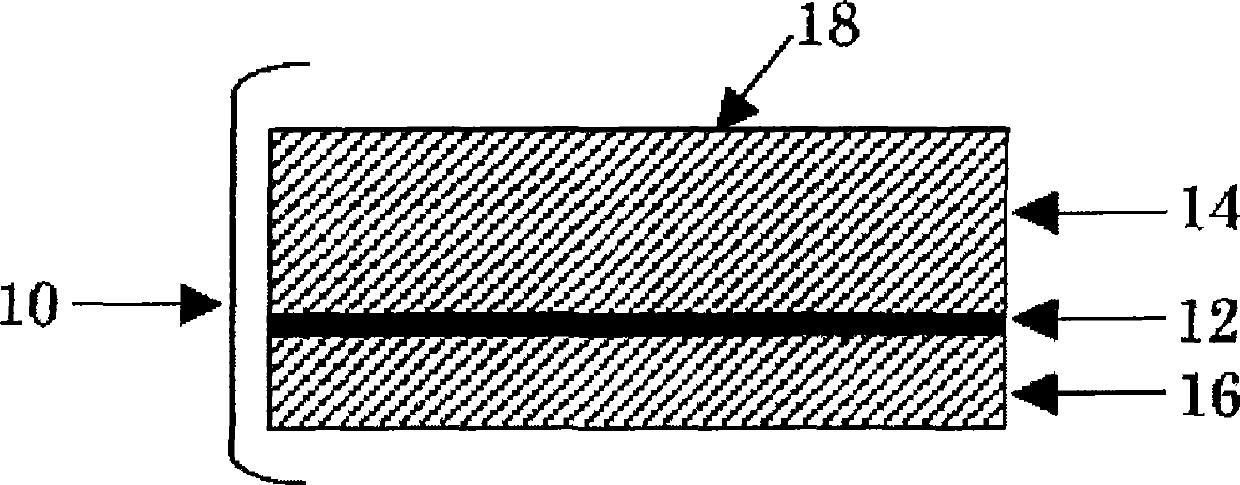

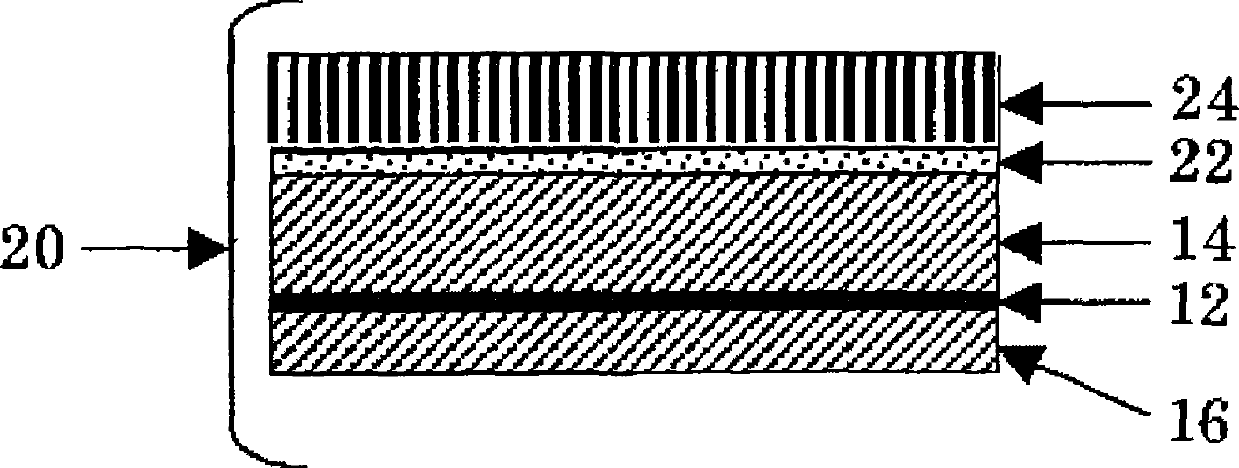

[0103] Polypropylene (propylene homopolymer, MFR (measured at a temperature of 230° C. and a load of 2.16 kg according to JIS K7210-1999): 65 g / 10 minutes) was used as a raw material of the spunbonded nonwoven fabric. Set the temperature of the molten resin at 220°C, the outflow of a single hole at 0.40g / min, the cooling wind speed at 1.4m / s, and the cooling air temperature at 25°C to obtain a fiber diameter of 1.2d, laminated 2-layer spunbonded nonwoven fabric, and the unit weight is 10.8g / m 2 The first SB nonwoven fabric 14.

[0104] Polypropylene (propylene homopolymer, MFR (measured at a temperature of 230° C. and a load of 2.16 kg according to JIS K7210-1999): 900 g / 10 minutes) was used as a raw material of the meltblown nonwoven fabric. Use an extruder to melt and knead at a molding temperature of 290°C, and extrude the obtained melt-kneaded product in a highly heated air flow with a melt blown die to obtain a fiber diameter of 2 μm and a mesh weight of 0.9 g / m 2 MB N...

Embodiment 2

[0111] In Example 1, the molding conditions were adjusted to obtain fiber diameters of 1.4d and mesh weights of 9.4g / m 2 The first SB nonwoven fabric 14 and the fiber diameter are 1.4d, and the weight is 4.7g / m 2 The second SB nonwoven fabric 16.

[0112] And the fiber diameter is 2μm, and the mesh weight is 0.9g / m 2 MB Nonwovens 12.

[0113] Other conditions were the same as in Example 1, and a nonwoven fabric laminate 10 was produced (the thickness of the first SB nonwoven fabric 14 was 148 μm, the thickness of the second SB nonwoven fabric 16 was 81 μm, the unit-to-pay ratio was 2.0, and the thickness ratio was 1.8. The total item payment is 15g / m 2 ) and the moisture-permeable nonwoven fabric laminated sheet 20 were evaluated and measured in the same manner as in Example 1 for each characteristic.

[0114] The results are shown in Table 1.

Embodiment 3~5

[0116] In Example 1, the molding conditions were adjusted to obtain a weight of 9.4g / m respectively. 2 (Example 3), 8.7g / m 2 (Example 4), 10.6g / m 2 The first SB nonwoven fabric 14 of (embodiment 5) and unit weight are 4.7g / m 2 (Example 3), 5.4g / m 2 (Example 4), 3.5g / m 2 The second SB nonwoven fabric 16 of (Example 5).

[0117] And the fiber diameter is 2μm, and the mesh weight is 0.9g / m 2 MB Nonwovens 12.

[0118] Other conditions are the same as in Example 1, and the nonwoven fabric laminate 10 [the thickness of the first SB nonwoven fabric 14 is 143 μm (Example 3), 130 μm (Example 4), 153 μm (Example 5), and the thickness of the first SB nonwoven fabric 14 is 153 μm (Example 5). The thickness of two SB nonwoven fabrics 16 is 78 μm (embodiment 3), 92 μm (embodiment 4), 69 μm (embodiment 5), and the unit payment ratio is 2.0 (embodiment 3), 1.6 (embodiment 4), 3.0 (implementation Example 5), the thickness ratio is 1.8 (embodiment 3), 1.4 (embodiment 4), 2.2 (embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com