Temperature fuse

A technology of thermal fuses and fuses, applied in emergency protection devices, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

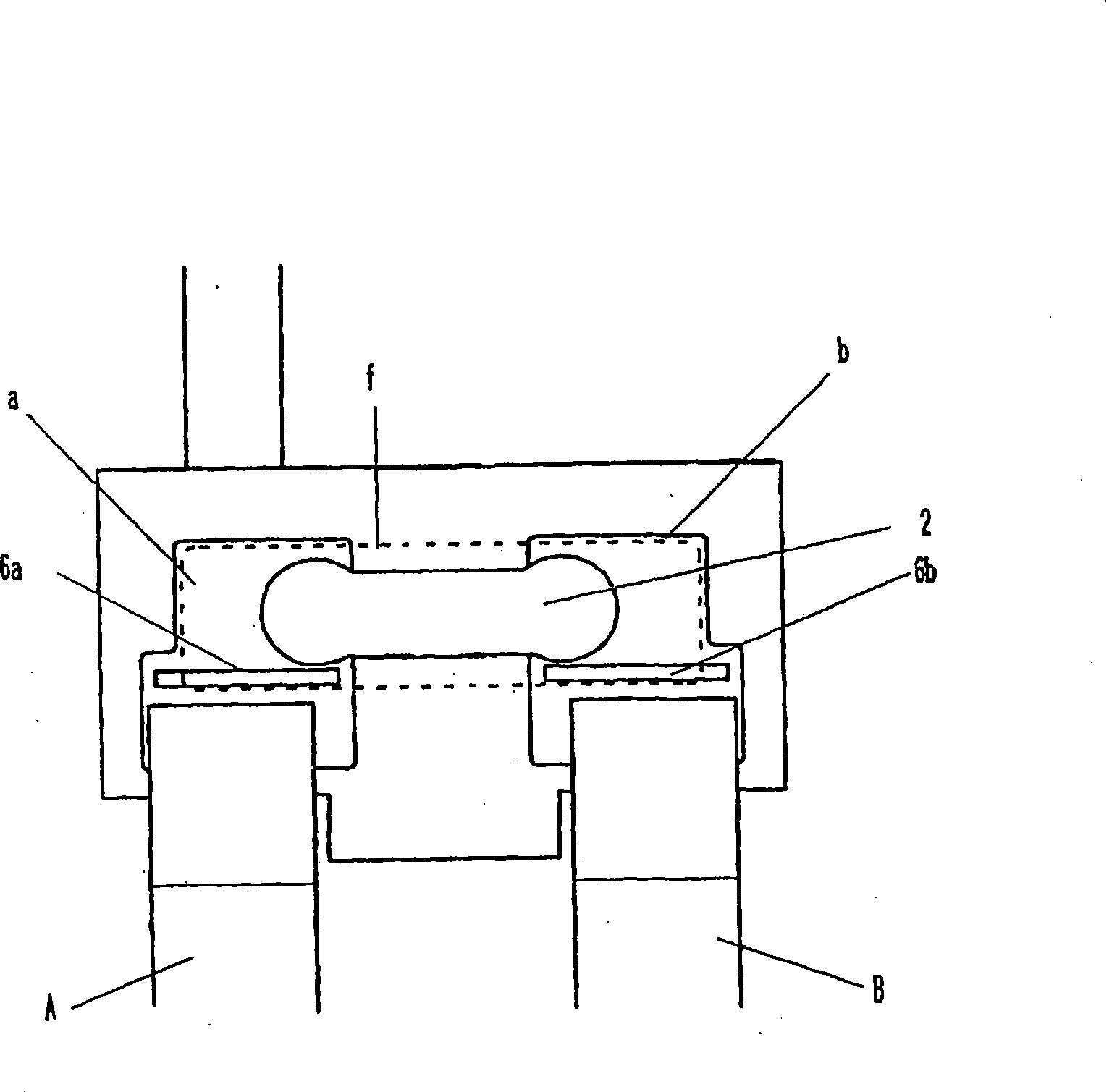

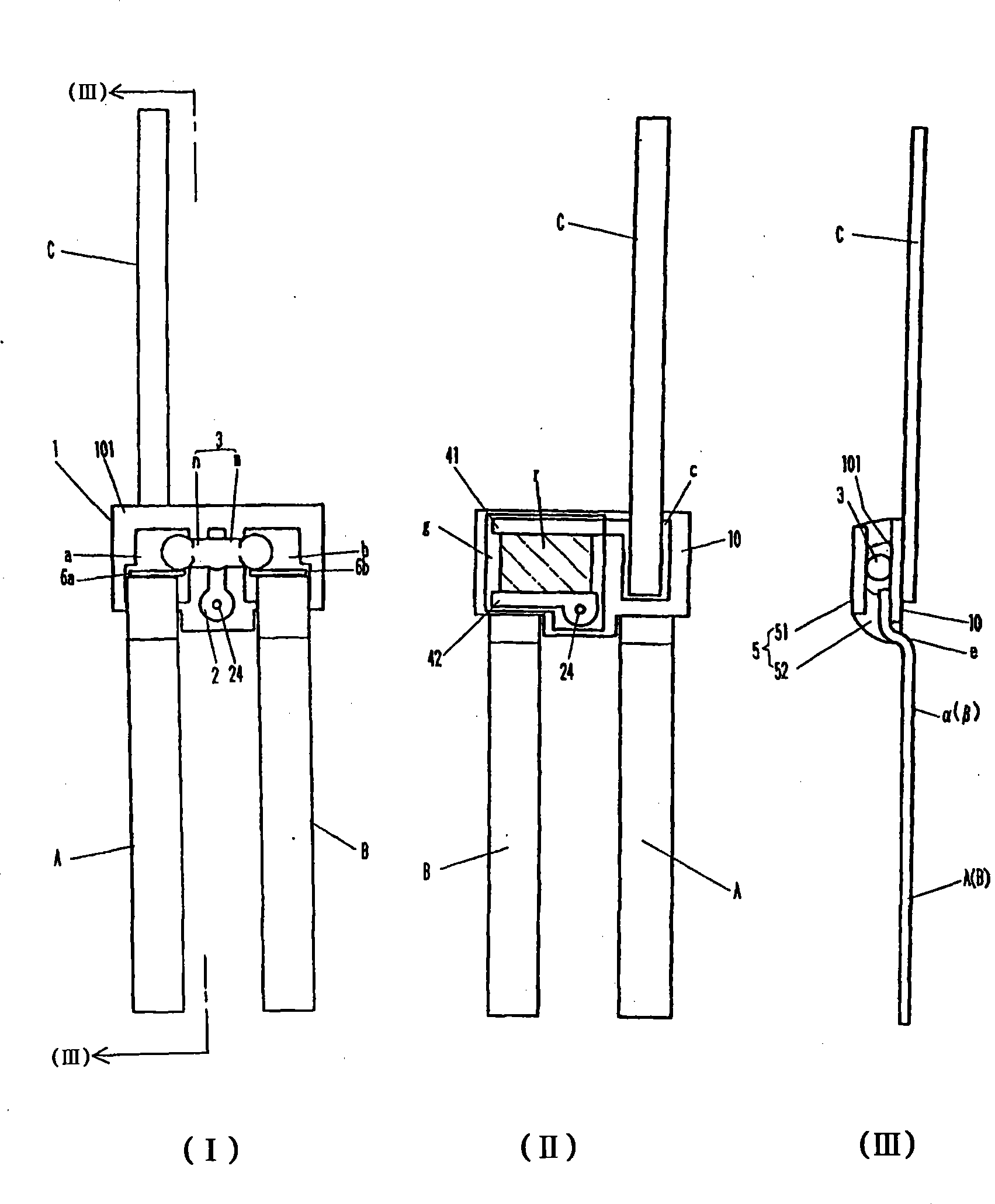

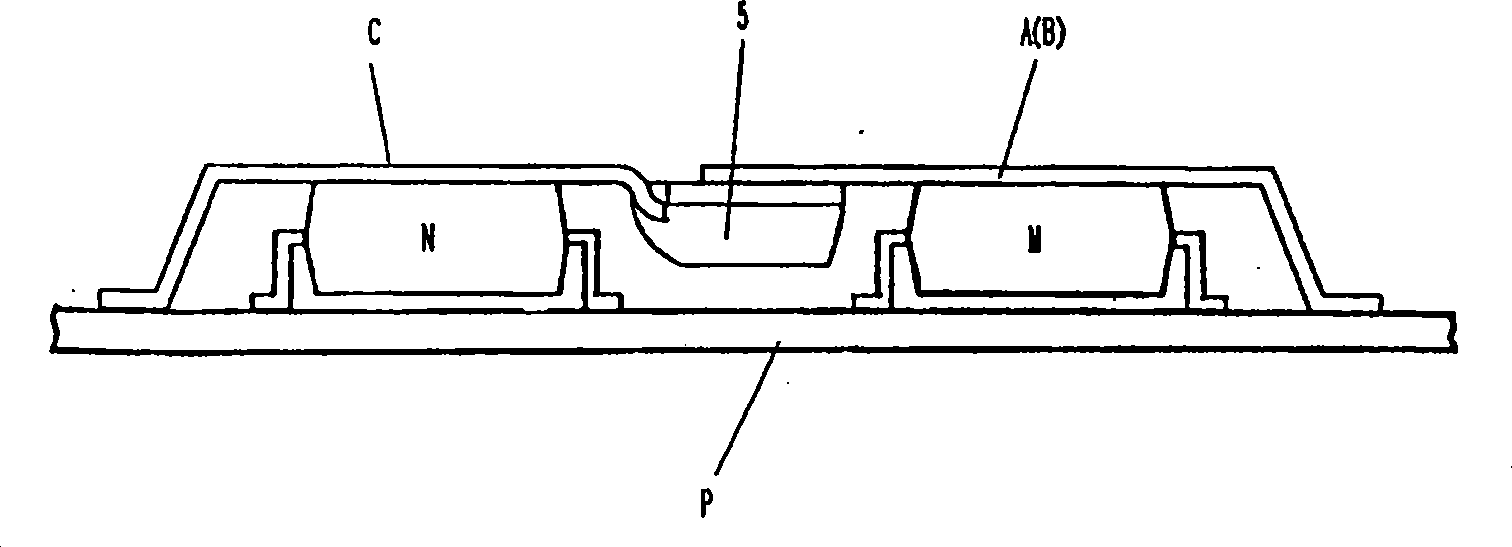

[0031] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described.

[0032] figure 1 It is a partially cutaway plan view showing an embodiment of the thermal fuse according to the present invention.

[0033] exist figure 1 Among them, 1 is an insulating substrate excellent in heat resistance and thermal conductivity, for example, a ceramic plate can be used. a and b are a pair of film electrodes for fuse element connection formed on one surface of the substrate, and can be provided by printing and firing a conductive paste such as silver paste. A and B are ribbon lead conductors, and the thickness of the ceramic plate 1 is as thin as 250 μm to 400 μm, and is soldered to the membrane electrode for fuse element connection. If welding, for example, spot welding lead conductors on an ultra-thin ceramic plate of 250 μm to 400 μm, there is concern about cracks and damage to the ceramic plate, but this disadvantage can be eliminated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com