Synchronous rack reciprocating blower with two vanes

A synchronous tooth and reciprocating technology, which is applied in the direction of oscillating piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of severe wear, large gas leakage rate, and alarming noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

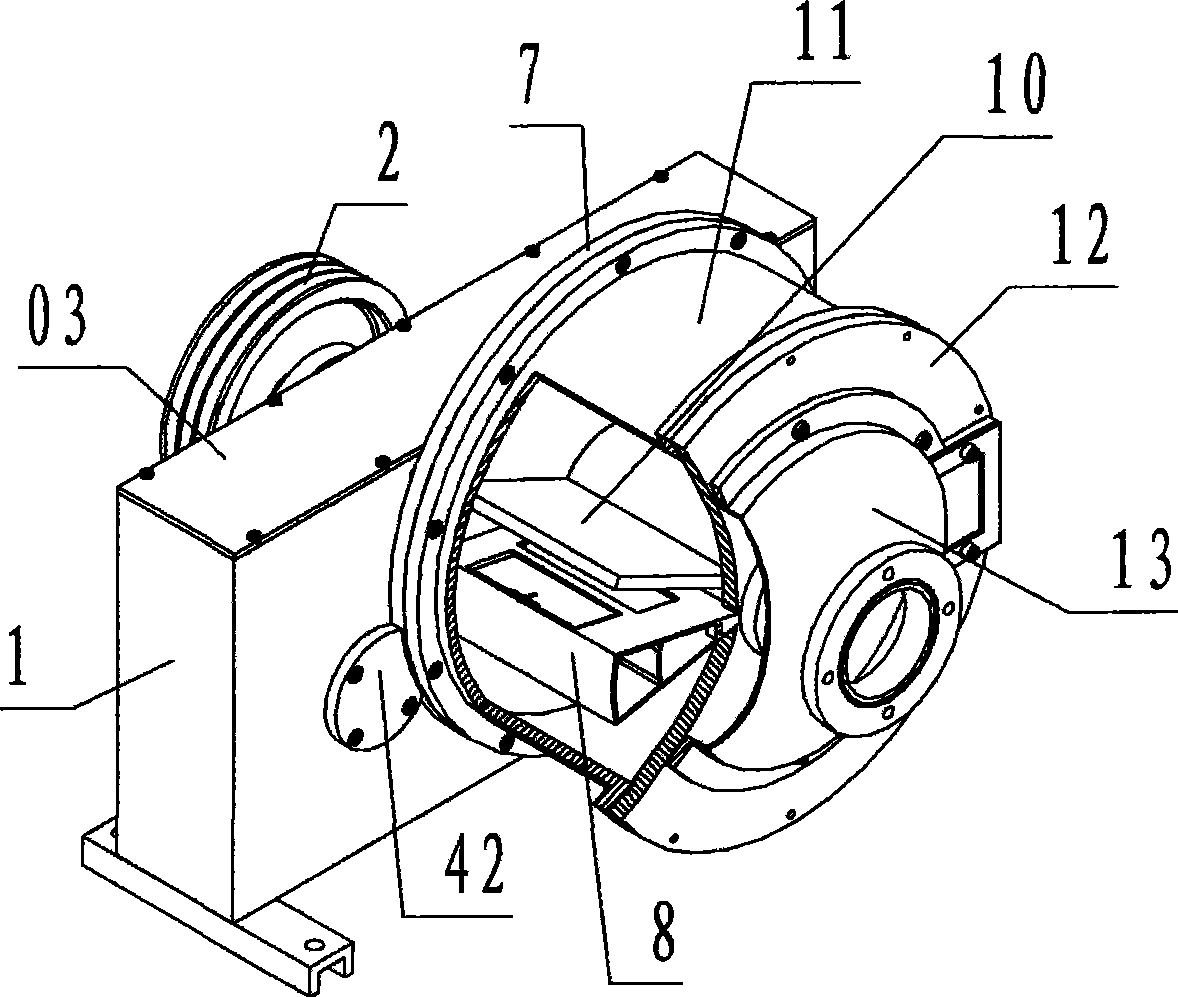

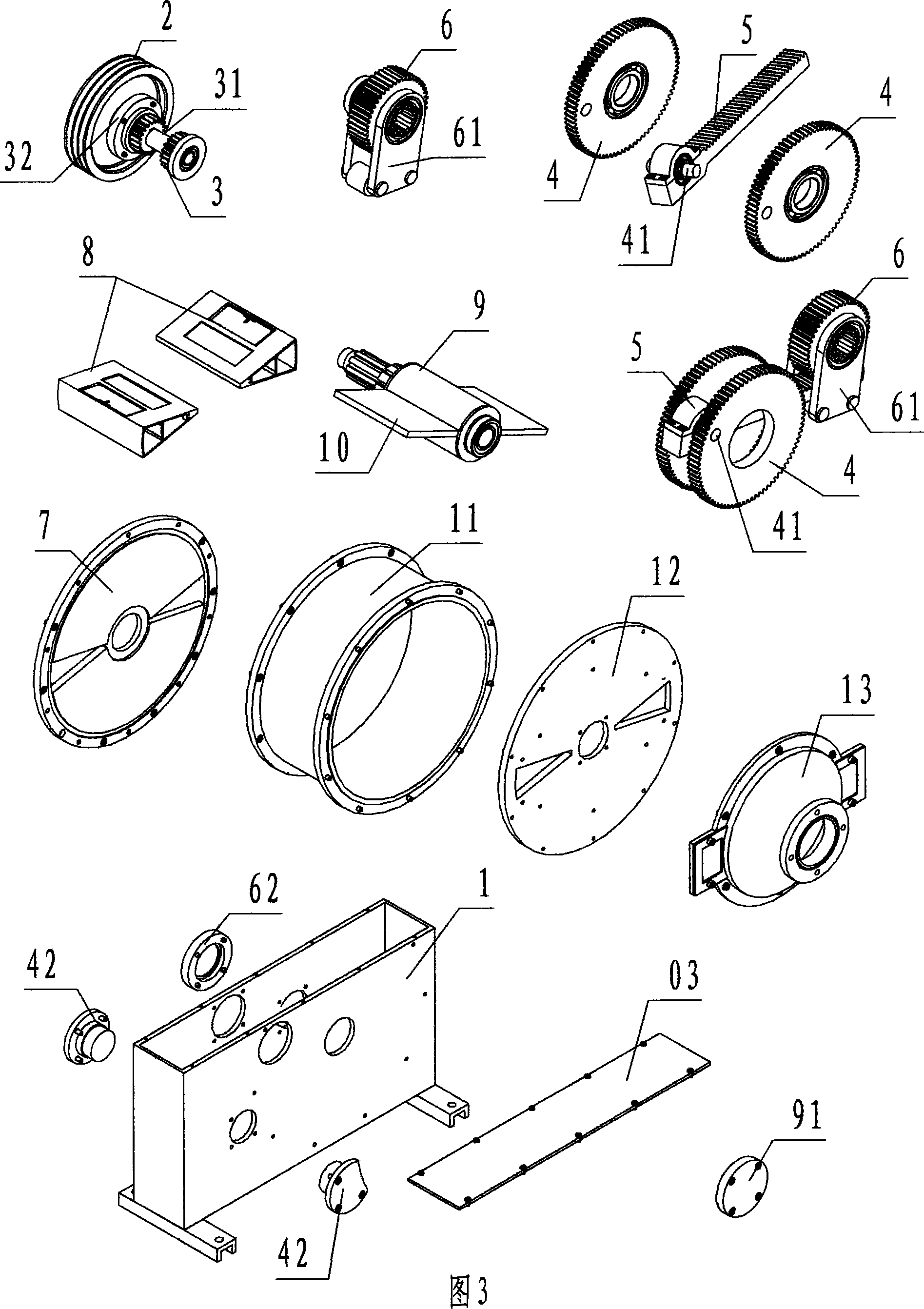

[0024] refer to figure 1 , figure 2, Fig. 3, a kind of two-leaf synchronous rack reciprocating blower of the present invention comprises gear case 1, belt pulley 2, reduction gear 3, reduction gear shaft 31, crankshaft gear 4, crankshaft 41, rocker rack 5, spline gear 6. Press wheel assembly 61, machine base 7, air valve 8, spline shaft 9, blade 10, casing 11, machine cover 12, air duct concentrator 13, wherein: the gearbox 1 is made of steel plate welded or The upper open front and rear side walls of the rectangular cast iron box are provided with several bearing holes and shaft holes, and are equipped with a box cover 03; the belt pulley 2 is a V-belt pulley with a shaft hole with a keyway in the center made of cast iron Described reduction gear 3 is that the center of cast iron or steel is provided with the cylindrical involute spur gear with keyway shaft hole; Described reduction gear shaft 31 is that one end (long end) is provided with the cylindrical step with keyway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com