Method for coating carbon nano-tube with metal doped zinc oxide nano-particle

A ZnO nanometer and metal-doped technology, which is applied in the field of metal-doped ZnO nanoparticle-coated carbon nanotubes, can solve the problems of difficult inorganic nanoparticle interaction, easy agglomeration surface activity, etc., and achieve low cost, particle size The effect of uniform diameter distribution and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

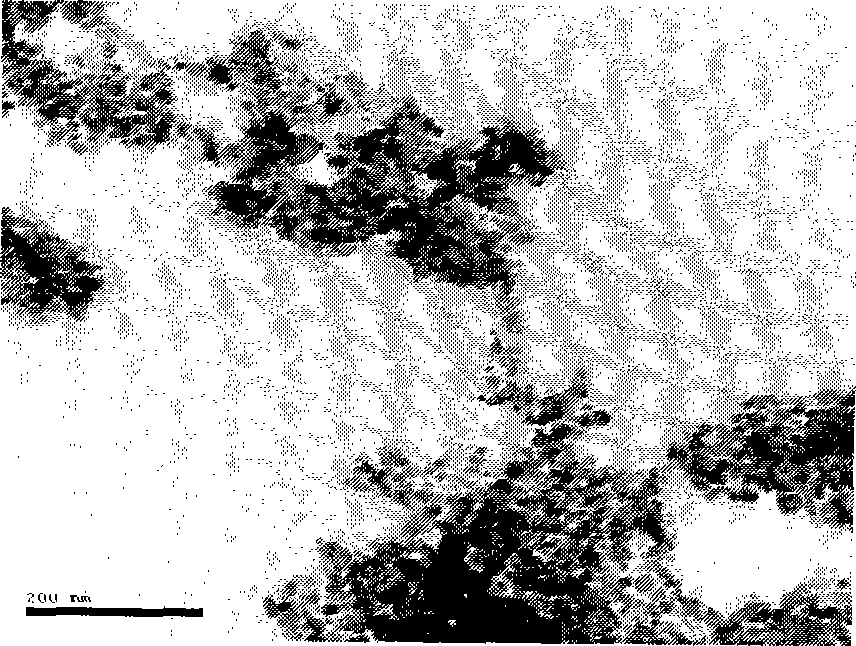

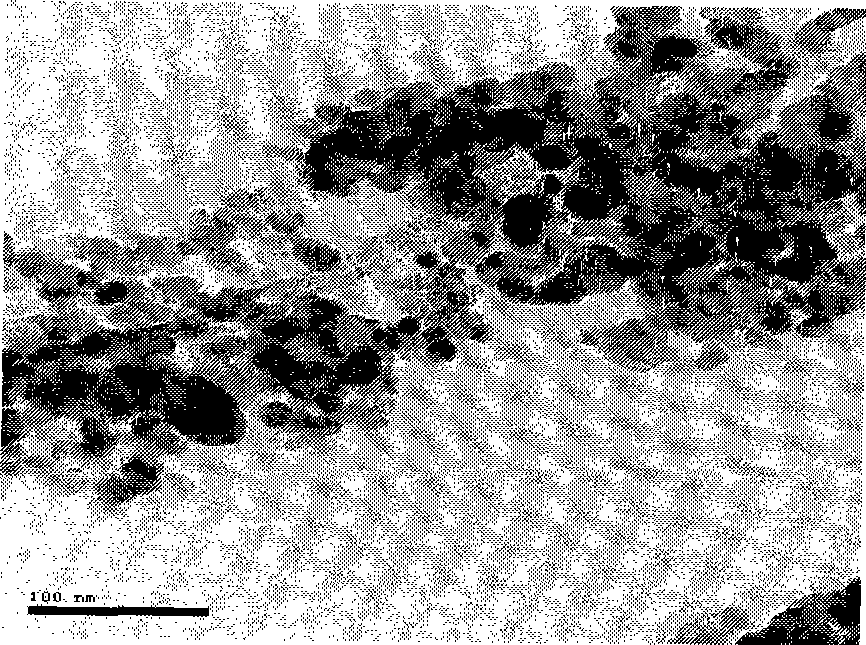

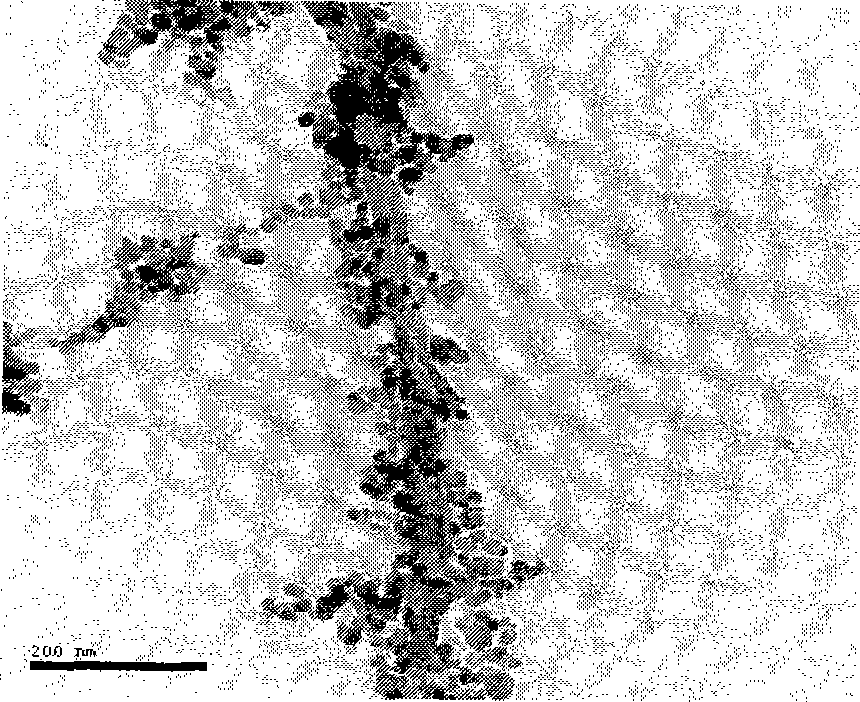

Image

Examples

Embodiment 1

[0023] 1) Dissolve 3 g of single-walled carbon nanotubes prepared by chemical vapor catalytic cracking in 500 mL of NaOH solution with a concentration of 2 mol / L, ultrasonically disperse for 30 min, reflux it for 2 h in a boiling state, then filter and rinse with deionized water several times , so that the pH value of the filtrate is neutral, and finally the obtained precipitate is dried and ground for later use;

[0024] 2) Add the carbon nanotubes obtained in the above step 1) to 500 mL of concentrated sulfuric acid and concentrated nitric acid mixed acid prepared at a volume ratio of 3:1, stir with a magnetic stirrer for 30 minutes, and then ultrasonically disperse for 30 minutes with an ultrasonic instrument, and then Heat to reflux at 100°C for 2h, filter the obtained precipitate and then use 500mL of analytically pure hydrochloric acid with a concentration of 2mol / L to reflux for 2h at 100°C, then filter and rinse with deionized water to make the pH of the filtrate until ...

Embodiment 2

[0028] 1) Dissolve 3 g of multi-walled carbon nanotubes prepared by chemical vapor catalytic cracking in 500 mL of 3 mol / L KOH solution, ultrasonically disperse for 30 min, reflux for 2 h in a boiling state, filter and rinse with deionized water several times, Make the pH value of the filtrate until neutral, and finally dry and grind the obtained precipitate for use;

[0029] 2) Add the carbon nanotubes obtained in the above step 1) to 500 mL of concentrated sulfuric acid and concentrated nitric acid mixed acid prepared at a volume ratio of 3:1, stir with a magnetic stirrer for 30 minutes, and then ultrasonically disperse for 30 minutes with an ultrasonic instrument, and then Heat to reflux at 100°C for 2h, filter the obtained precipitate and then use 500mL of analytically pure hydrochloric acid with a concentration of 2mol / L to reflux for 2h at 100°C, then filter and rinse with deionized water to make the pH of the filtrate until neutral. Finally, dry and grind the obtained p...

Embodiment 3

[0033]1) Dissolve 3g of single-walled carbon nanotubes prepared by chemical vapor catalytic cracking in 500mL of 1mol / L ammonia solution, stir with a magnetic stirrer for 30min, and then disperse it with an ultrasonic instrument for 30min, then reflux it in a boiling state 2h, then filter and rinse several times with deionized water to make the pH of the filtrate neutral, and finally dry and grind the obtained precipitate for use;

[0034] 2) Add the carbon nanotubes obtained in the above step 1) into 500 mL of concentrated sulfuric acid and concentrated nitric acid mixed acid prepared at a volume ratio of 3:1, stir with a magnetic stirrer for 30 minutes, and then ultrasonically disperse for 30 minutes with an ultrasonic instrument, and then in 100 Heat to reflux at ℃ for 2h, filter and then reflux the obtained precipitate with 500mL of analytically pure hydrochloric acid with a concentration of 2mol / L at 100℃ for 2h, then filter and rinse with deionized water to make the pH of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com