Engine with rotary piston

A piston and piston rod technology, applied in the field of reciprocating piston machines, can solve the problems of difficult to filter out impurities, dirty motor parts, difficult time cycle, etc., and achieve the effect of simple maintenance, easy assembly, reduced weight and required space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

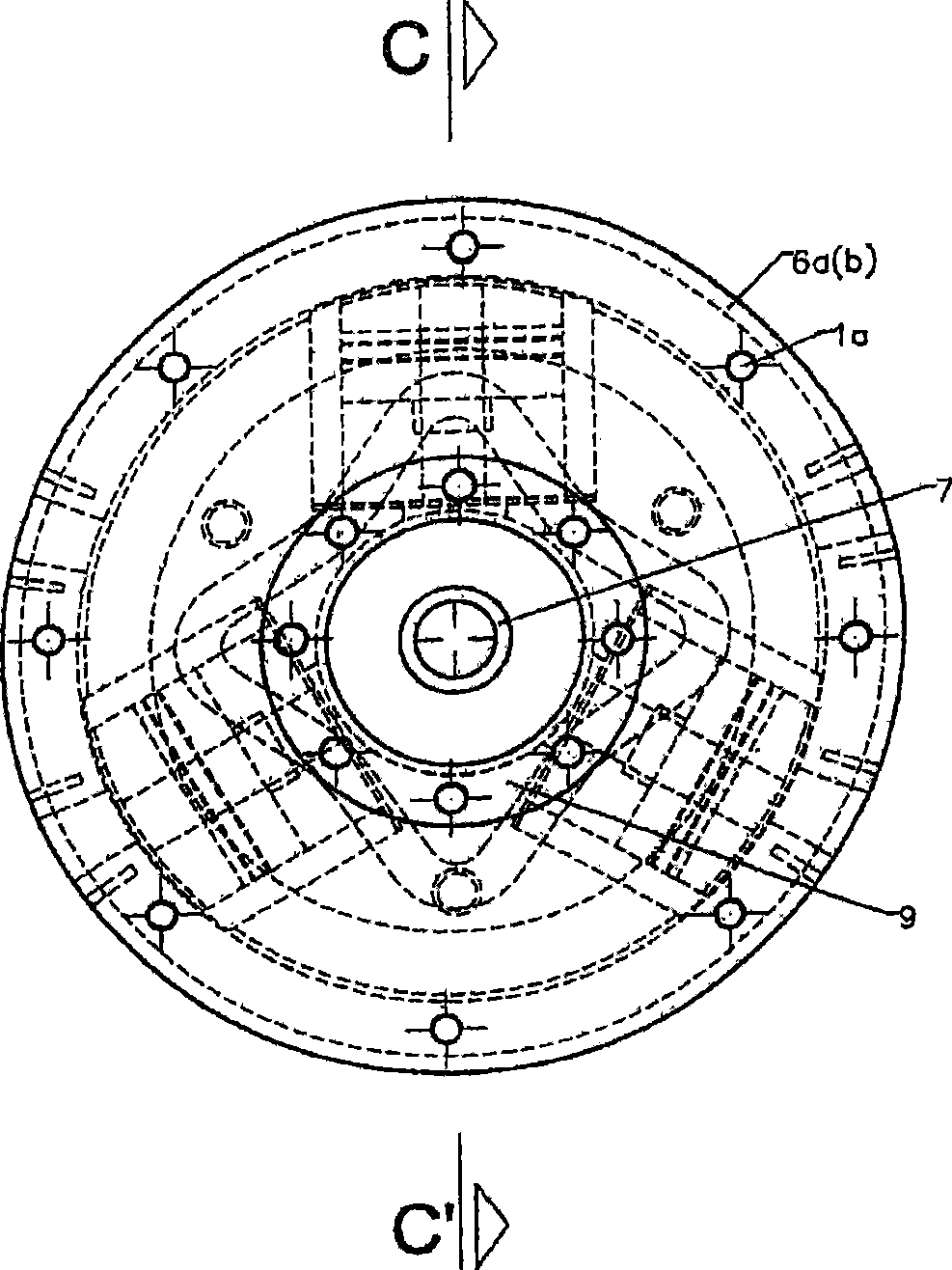

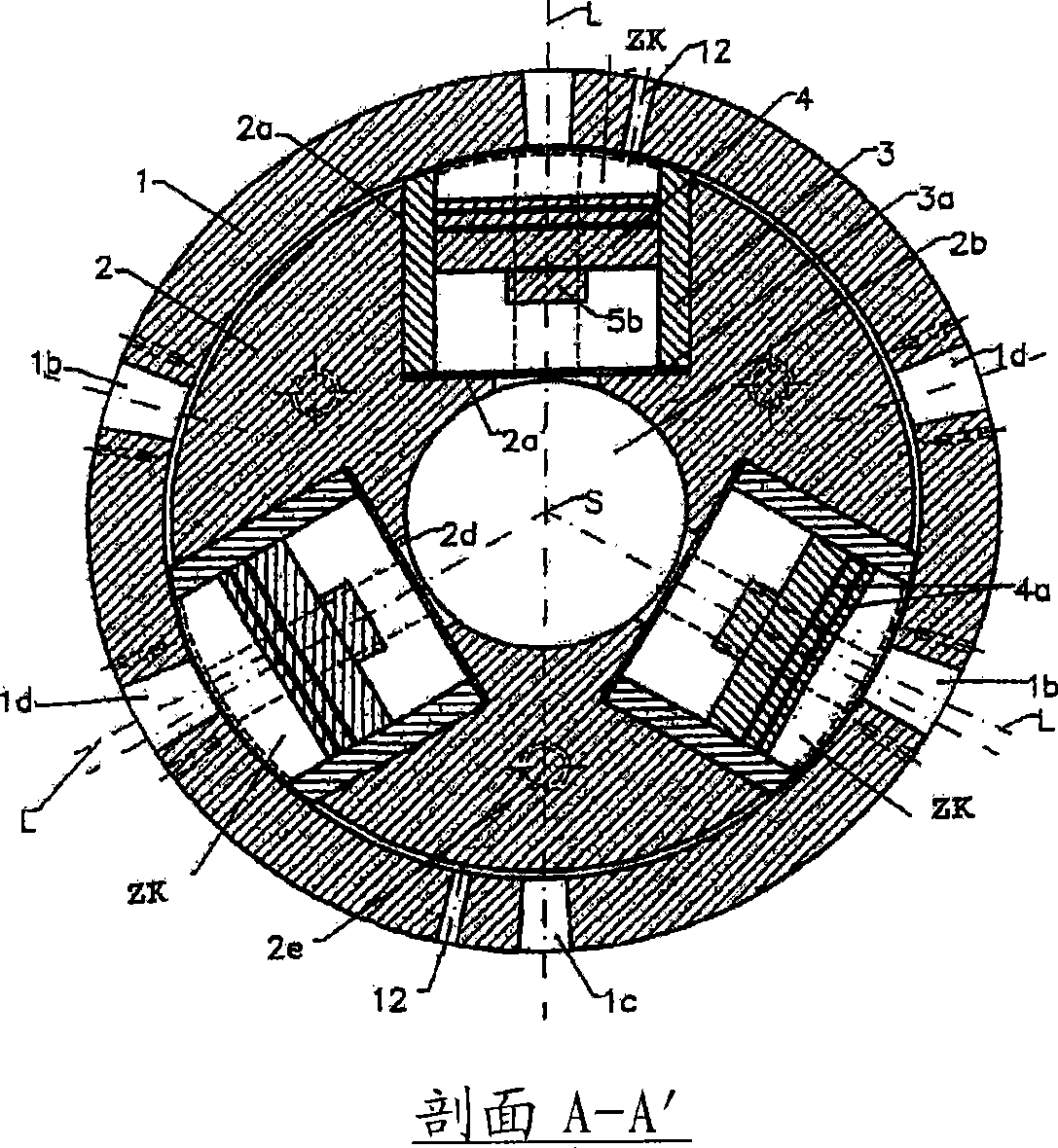

[0027] The application of a rotary reciprocating piston machine as a motor or internal combustion engine will now be described. However, as indicated above, the rotary reciprocating piston machine according to the invention can also be operated as a pump or compressor.

[0028] Furthermore, a rotary reciprocating piston machine will be described below with reference to an embodiment provided with three pistons, but the engine may also be a one or two piston engine, or may be provided with four or more pistons.

[0029] Furthermore, a rotary reciprocating piston machine will be described hereinafter in connection with a star-shaped guide track for two four-stroke work cycles per piston and per rotor revolution. Other guide tracks may also be provided, as described below.

[0030] will now refer to Figures 1 to 8 A rotary reciprocating piston machine is described in more detail. as from Figure 4 As can be seen most clearly in , the rotary reciprocating piston machine has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com