Novel lithium iron phosphate anode material used for lithium ion battery and method of manufacturing the same

A lithium-ion battery, lithium iron phosphate technology, applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems that cannot meet the specific capacity and cycle performance requirements of high-rate charge-discharge batteries, and achieve good battery cycles Performance, broad application prospects, effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix 3 moles of lithium fluoride, 2.94 moles of ferrous oxalate, 2.94 moles of ammonium dihydrogen phosphate, and 0.03 moles of sodium thiosulfate, add 1000ml of deionized water and 30ml of industrial alcohol, seal and ball mill (600-800r / min) for 8 hours , the discharge was dried at 100°C and then ball-milled (700r / min) for 4 hours. Under nitrogen protection, the temperature was raised to 360°C at a rate of 2°C / min. / min) mixed for 4 hours, after briquetting, the temperature was raised to 700°C at a rate of 3°C / min under the protection of nitrogen, kept at this temperature for 10 hours, and then dropped to room temperature with the furnace temperature, and after shape shaping, LiFe 0.98 Na 0.02 P 0.98 S 0.02 o 4 Lithium iron phosphate powder positive electrode material, denoted as sample A.

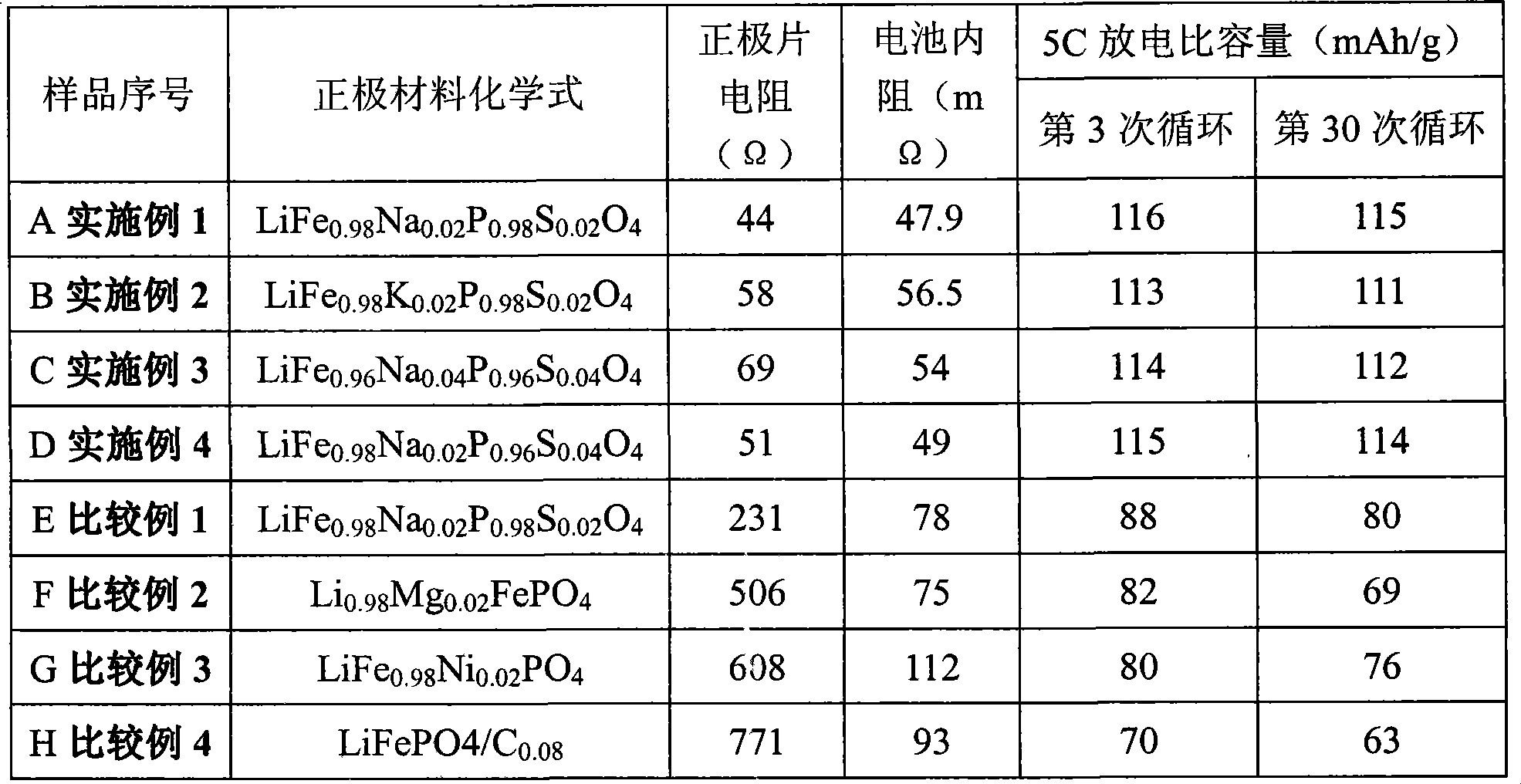

[0038] The electrochemical performance of gained sample is measured by following method, takes by weighing 100g sample A (LiFe 0.98 Na 0.02 P 0.98 S 0.02 o 4 ) lithium iro...

Embodiment 2

[0040] 3 moles of lithium fluoride, 2.94 moles of ferrous oxalate, 2.94 moles of ammonium dihydrogen phosphate and 0.03 moles of potassium thiosulfate were mixed, and the rest of the steps were the same as in Example 1 to obtain LiFe 0.98 K 0.02 P 0.98 S 0.02 o 4 Lithium iron phosphate powder, denoted as sample B.

[0041] According to the method of Example 1, use sample B to make a battery pole piece and measure the resistance of the positive pole piece; assemble a battery and measure the internal resistance of the battery, charge to 4.0V at a rate of 5C, and discharge to 2.0V to obtain the third cycle discharge ratio of the battery The capacity is 113mAh / g, and the specific capacity after 30 cycles of discharge is 111mAh / g, see the simulation battery test table.

Embodiment 3

[0043] 3 moles of lithium fluoride, 2.88 moles of ferrous oxalate, 2.88 moles of ammonium dihydrogen phosphate and 0.06 moles of sodium thiosulfate were mixed, and the remaining steps were the same as in Example 1 to obtain LiFe 0.96 Na 0.04 P 0.96 S 0.04 o 4 Lithium iron phosphate powder, denoted as sample C.

[0044] According to the method of Example 1, use sample C to make battery pole pieces and measure the resistance of the positive pole piece; assemble the battery and measure the internal resistance of the battery, charge to 4.0V at a rate of 5C, and discharge to 2.0V to obtain the third cycle discharge ratio of the battery The capacity is 114mAh / g, and the specific capacity after 30 cycles of discharge is 112mAh / g, see the simulation battery test table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com