Phase-change heat-storage electrical heater

A phase-change heat storage and phase-change technology, which is applied in household heating, heating methods, electric heating systems, etc., can solve the problem of not being able to provide heating for a long time, and achieve the effect of extending the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

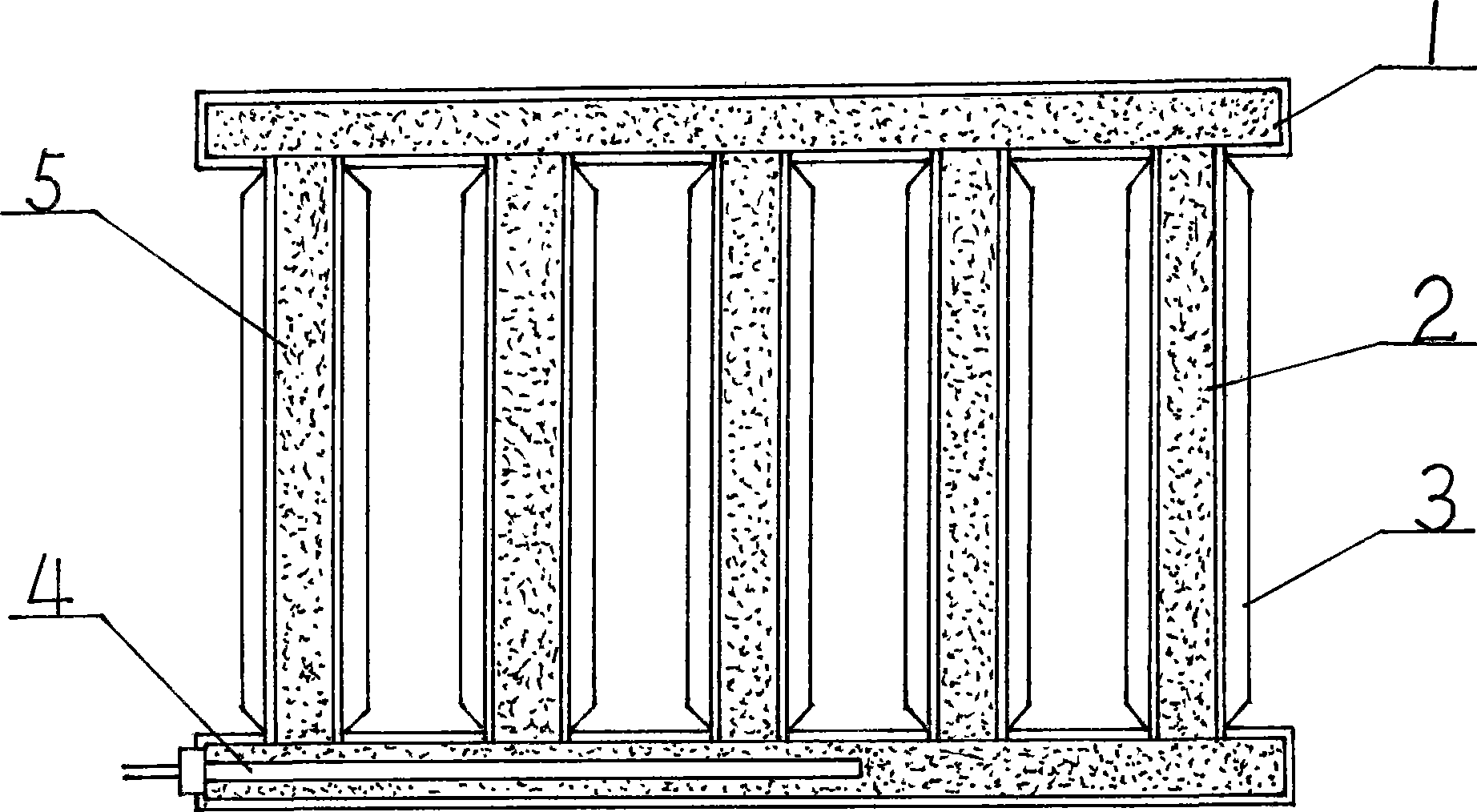

[0008] In the accompanying drawings, in a radiator housing 1, an electric heating tube is installed at the bottom thereof, and the upper part is filled with a phase-change heat storage agent 5. Radiator fins 3 are welded on the outside of the radiator channel tube 2 for heat dissipation. When the heating tube 4 is energized, it generates heat, which is absorbed by the phase-change heat storage agent 5 and changes from solid to liquid, and heats up through the radiator channel tube 2 and cooling fins 3 . When the electric heating tube 4 is powered off to stop heating, the phase-change heat storage agent 5 releases the stored latent heat, and continues heating through the radiator channel tube 2 and heat sink 3. At this time, the phase-change heat storage agent changes from liquid to solid state, and the reciprocating cycle Make the phase change heat storage ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com