Frame head apparatus of translational rotary compressor

A rotary compressor, translational technology, used in rotary piston machinery, components of pumping devices for elastic fluids, rotary piston/oscillating piston pump components, etc., can solve the machine compression heat and friction. Heat can not be quickly discharged, the cylinder is bulky, and the heat dissipation performance is poor, so as to improve the heat dissipation effect and compression efficiency, simplify the processing technology, and improve the mechanical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

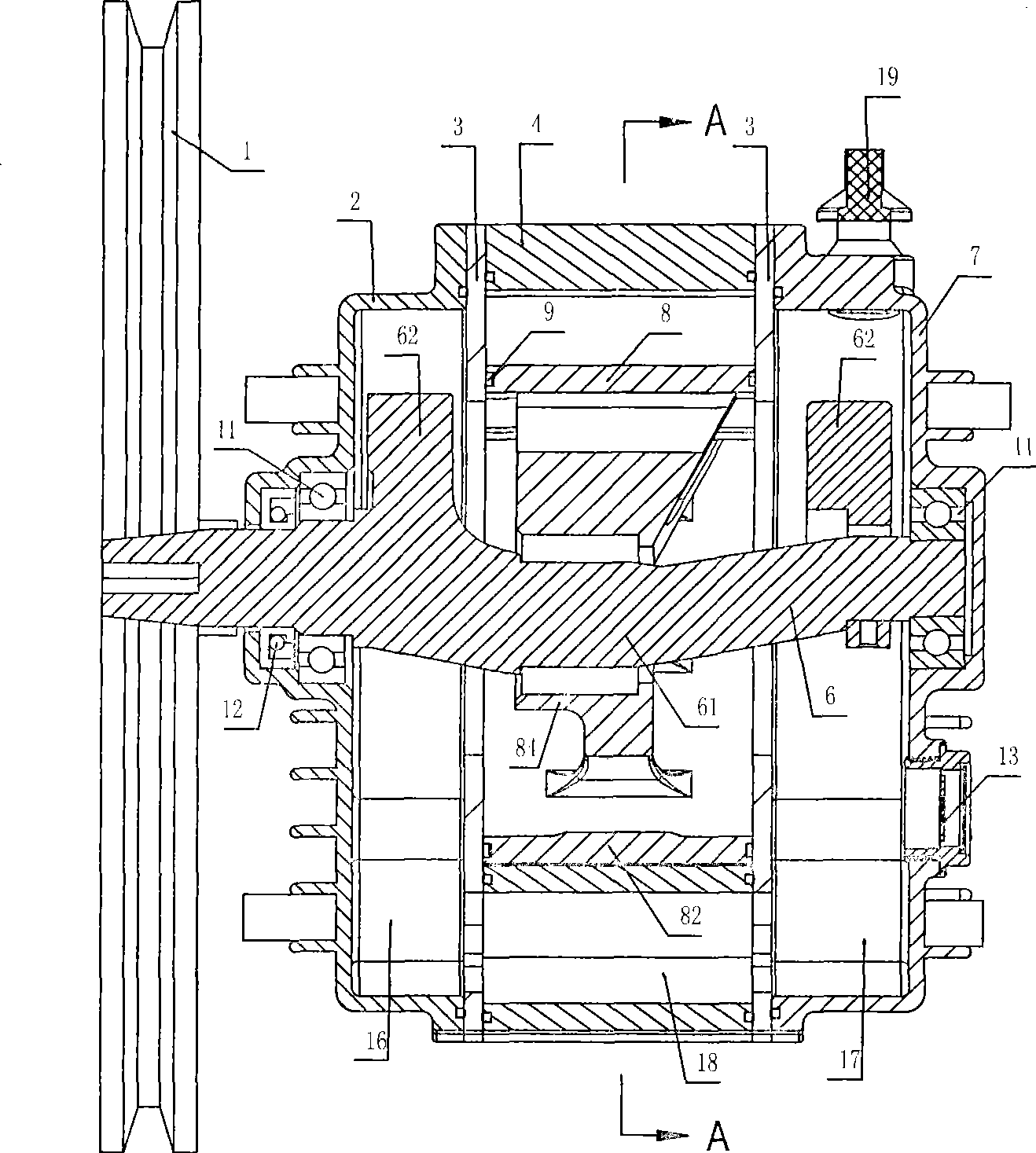

[0034] like figure 1 The machine head device of the translational rotary compressor shown, the device includes a cylinder body 4, a crankshaft 6, a transmission wheel 1, a slide plate 5 and a translational piston 8, and the two ends of the cylinder body 4 are respectively provided with a left end cover 2 and a right end cover 7 , the left end cover 2, the right end cover 7 and the cylinder body 4 are respectively provided with a piston baffle 3, the left end cover 2, the right end cover 7, the cylinder body 4 and the piston baffle 3 are fixedly connected by bolts, the left end cover 2 and the piston baffle 3. Sealing rings are respectively provided between the right end cover 7 and the piston baffle 3 , and between the cylinder body 4 and the piston baffle 3 . like figure 1 As shown, cavities are respectively formed between the left end cover 2, the right end cover 7 and the piston baffle 3, the bottom of the cylinder body 4 is provided with an oil groove 18, and the oil groo...

Embodiment 2

[0042] Such as Figure 5 , Figure 6 As shown, the translational piston 8 includes an inner wall body 84 and an outer wall body 82 , the inner wall body 84 and the outer wall body 82 are connected by a fixed panel 87 , and a plurality of cooling through holes 88 are provided on the fixed panel 87 . Other structural features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com